Top OEMs for Butterfly Valves

Introduction

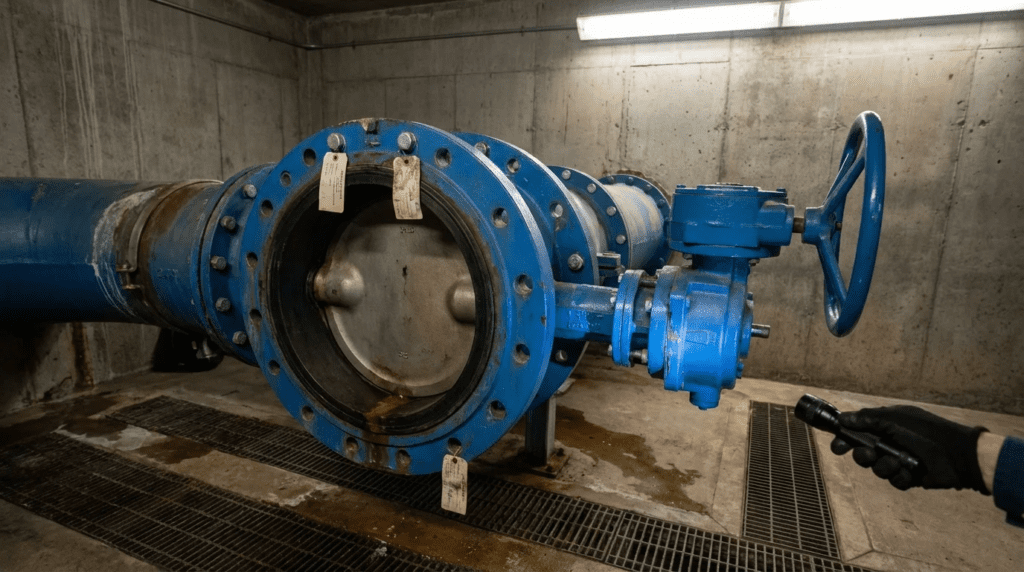

In the landscape of municipal and industrial water and wastewater infrastructure, the butterfly valve represents one of the most ubiquitous and critical components for flow control and isolation. Characterized by a quarter-turn rotary motion and a relatively compact footprint, butterfly valves are utilized across a vast spectrum of applications—from raw water intake and high-pressure transmission mains to wastewater treatment plant aeration systems and sludge handling.

For consulting engineers, plant superintendents, and utility decision-makers, the selection of a butterfly valve Original Equipment Manufacturer (OEM) is rarely a matter of simple commodity purchasing. The operating environments in water treatment plants (WTP) and wastewater treatment plants (WWTP) are notoriously unforgiving. Valves are subjected to galvanic corrosion, abrasive grit, cavitation, hydraulic transients (water hammer), and the degrading effects of chemical additives such as chloramines or ferric chloride.

While the fundamental design of a butterfly valve—a disc rotating on a shaft within a body—appears simple, the engineering nuances distinguishing one OEM from another have profound implications for lifecycle costs. Issues such as seat retention methods, shaft-to-disc connection integrity, bearing materials, and coating specifications determine whether a valve will function reliably for 40 years or fail within five. Furthermore, regulatory standards, specifically AWWA C504 (Rubber-Seated Butterfly Valves), AWWA C516 (Large-Diameter), and NSF/ANSI 61/372 (Drinking Water System Components), impose strict baselines that manufacturers must meet or exceed.

This article provides an engineer-focused evaluation of top OEMs in the butterfly valve market. It moves beyond marketing rhetoric to analyze the mechanical attributes, design philosophies, and application suitability of specific manufacturers. The goal is to equip specifying engineers and end-users with the technical context required to write defensible specifications and select equipment that ensures operational continuity.

How to Select This Valve Type

Selecting the correct butterfly valve requires a holistic engineering approach that balances hydraulic performance, mechanical durability, and maintainability. Engineers must evaluate the following technical criteria to ensure the selected valve meets the specific duty cycle of the application.

1. Valve Geometry and Seat Design

The primary design distinction in butterfly valves is the offset of the shaft relative to the seal.

- Concentric (Zero Offset): The shaft passes through the centerline of the disc and the seat. This is the standard resilient-seated design used in most low-to-medium pressure water applications. The interference fit between the disc and the rubber liner provides the seal. While cost-effective, the constant friction between the disc and seat can lead to wear over high cycle counts.

- Double Offset (High Performance): The shaft is offset from the centerline of the disc and the centerline of the bore. This cam-action design allows the disc to lift off the seat immediately upon opening, reducing friction and wear. These are preferred for higher pressures, higher temperatures, or modulating service.

- Triple Offset: Utilized primarily in extreme industrial applications or high-pressure steam/gas, featuring a metal-to-metal seal. While less common in standard municipal water, they are seen in power generation and specific industrial wastewater processes.

2. Seat Retention and Materials

The method of seat retention is a frequent point of failure. Engineers must specify based on repairability requirements:

- Bonded/Vulcanized Seats: The elastomer is vulcanized directly to the valve body. This eliminates the risk of seat collapse or “bunching” under high flow or vacuum conditions. However, these seats are typically not field-replaceable; a damaged seat often requires a full valve replacement or factory refurbishment.

- Mechanically Retained Seats: The seat is held in place by a retaining ring or hardware. These are field-replaceable, which is advantageous for large-diameter valves where removing the body from the line is logistically difficult. However, the hardware presents potential crevice corrosion sites if not properly specified (e.g., 316SS hardware).

- Seat-on-Disc vs. Seat-in-Body: In large diameter AWWA valves, the rubber seat is often mounted on the disc edge, mating with a stainless steel seat ring in the body. This allows for adjustment of the seat compression to ensure bubble-tight shutoff over time.

3. Shaft and Connection Engineering

The connection between the shaft (stem) and the disc is the transmission point for torque. Weakness here leads to hysteresis (slop) in control or total failure.

- Through-Shaft vs. Stub Shaft: A through-shaft provides continuous support but restricts flow capacity (Cv). Stub shafts maximize flow but rely heavily on the disc structure for rigidity.

- Connection Methods: Taper pins, tangential pins, and splined connections are common. Tangential pins are generally preferred in high-vibration applications as they are mechanically locked and less prone to backing out than standard taper pins. Splined connections offer high torque transmission with zero play, ideal for modulating control.

4. Actuation and Operating Torque

Proper actuator sizing requires calculating not just seating/unseating torque, but also dynamic torque (fluid dynamic forces acting on the disc). In high-velocity applications, the flow can create a hydrofoil effect that tends to close the valve (self-closing torque). Actuators must be sized with adequate safety factors (typically 1.25 to 1.5) to handle “breakaway” torque after long periods of inactivity, where the rubber seat may have taken a compression set or adhered to the disc.

5. Cavitation and Flow Characteristics

Butterfly valves have a high recovery factor, making them susceptible to cavitation when used for throttling at high pressure drops. Engineers must evaluate the Sigma factor and potential for incipient cavitation. For severe throttling, anti-cavitation trims or alternative valve types (like plunger valves) may be required, though some high-performance butterfly valves handle modulation well within a 30% to 70% open range.

Comparison Table

The following table provides a technical comparison of the designated OEMs. This table is not a ranking system but a guide to understanding the primary engineering focus, design strengths, and typical application ranges of each manufacturer. It is intended to help engineers align the specific constraints of their project—such as pressure class, media type, or installation footprint—with the most appropriate manufacturer portfolio.

| OEM Name | Core Valve Technologies | Primary Strengths | Limitations / Constraints | Best-Fit Applications |

|---|---|---|---|---|

| Henry Pratt | Rubber-Seated AWWA C504; Concentric Design; Truss-style Disc | Industry-standard reliability for municipal water; E-Lok® seat design allows field adjustment; extensive large-diameter experience. | Standard designs may struggle in severe abrasive slurry without specialized trims; heavy reliance on custom specs for non-standard pressures. | Municipal potable water distribution; Water treatment plant isolation; Buried service. |

| DeZURIK | BAW (AWWA) Series; BHP (High Performance); Seat-on-Body and Seat-on-Disc options | Exceptional corrosion resistance options; robust shaft-to-disc pinning; designs specifically engineered for both water and wastewater solids. | Premium engineering often carries a higher initial capital cost compared to commodity valves; heavier weight in some large diameter classes. | Wastewater treatment (aeration, sludge); Pump isolation; Industrial process water. |

| Bray International | Resilient Seated (Series 30/31); High Performance Double Offset (Series 40/41) | Modular design ideal for automation; extensive stock and distribution network; high-performance options handle higher pressures/temps. | Heritage is stronger in industrial/HVAC than large-scale AWWA civil infrastructure; light-duty series not suitable for buried service. | Plant automation; HVAC cooling water; Industrial wastewater; Chemical handling (with PTFE liners). |

| VAG | EKN® Double Eccentric; TEWS (Telescopic); Plunger Valves | EKN design offers “lift and turn” motion to reduce seat wear; massive diameter capabilities; superior hydrodynamics for transmission lines. | European design standards (DIN/ISO) occasionally require careful spec coordination for US retrofit projects (flange drilling, etc.). | High-pressure transmission mains; Dams and reservoirs; Pump discharge control; Severe duty isolation. |

| Crispin Valve | K-Flo Series (47/500); Butterfly/Check combinations | Legacy of the K-Flo design; Lens-shaped discs maximize flow coefficient (Cv); Strong domestic manufacturing footprint. | Product portfolio is more focused on clean water and specific AWWA niches than extreme industrial chemical processing. | Raw water intake; Potable water distribution; Filter gallery isolation. |

| DHC International | Concentric Wafer/Lug; AWWA C504 variants | Cost-effective solutions for general purpose isolation; strong focus on meeting dimensional interchangeability. | Less focus on highly engineered, custom-fabricated large-scale infrastructure projects compared to Pratt/VAG. | General plant service; Low-pressure irrigation; Auxiliary water systems. |

Top OEM Manufacturers

The following section details the engineering profiles of the six mandatory OEMs. This analysis focuses on their manufacturing capabilities, design philosophies, and suitability for critical water and wastewater infrastructure.

Henry Pratt

Henry Pratt is arguably the most recognizable name in the North American municipal water butterfly valve market. Historically, Pratt is credited with pioneering the rubber-seated butterfly valve, essentially setting the benchmark for what became the AWWA C504 standard. Their engineering philosophy centers on long-term reliability in buried and plant service applications.

From a technical standpoint, Pratt’s hallmark is the “E-Lok” seating system and the “Triton” and “Groundhog” valve designs. The E-Lok seat is a mechanically retained rubber seat located in the valve body (as opposed to on the disc). This design allows for field adjustment and replacement without dismantling the valve disc or shaft, a critical feature for maintenance in large-diameter piping galleries. The seat is retained by epoxy or stainless steel segments, preventing the “pop-out” failure mode common in inferior bonded seat designs.

Pratt utilizes a flow-through disc design (often a truss or lens shape) to maximize strength-to-weight ratios while minimizing head loss. Their shafts are typically constructed of Type 304 or 316 stainless steel, utilizing a specific connection geometry that ensures robust torque transmission. For consulting engineers, Pratt represents the “safe specification” for potable water distribution, offering a vast installation base and proven longevity.

Crispin Valve

Crispin Valve, while historically famous for air release valves, has established a significant footprint in the butterfly valve market, particularly following their acquisition and integration of the K-Flo product line. The Crispin (K-Flo) Series 47 and Series 500 are staples in the municipal water sector, designed strictly to AWWA C504 standards.

The engineering strength of the Crispin line lies in its hydraulic efficiency. Their disc designs are streamlined to provide high flow coefficients (Cv) and low pressure drops, which contributes to lower energy pumping costs over the lifecycle of the system. The valves feature a seat-on-body design in smaller sizes and options for seat-on-disc in larger configurations. They utilize stainless steel shafts with self-lubricating sleeve bearings, typically PTFE-lined, to lower operating torque and reduce actuator size requirements.

Crispin is particularly favored in raw water and potable water applications where domestic manufacturing (Buy American Act compliance) is a priority. Their designs focus on simplicity and ruggedness, minimizing the number of internal parts to reduce failure points.

DHC International

DHC International operates within the valve market providing a range of flow control products including resilient seated butterfly valves. While they may not have the century-long history of Pratt or DeZURIK in the municipal space, DHC serves a vital role in providing cost-competitive, standards-compliant valves for general utility and industrial service.

DHC’s product line typically includes concentric wafer and lug style valves that comply with MSS SP-67 and API 609, as well as AWWA C504 compliant double flanged models. Their engineering approach focuses on interchangeability and broad chemical compatibility. They utilize phenolic-backed or aluminum-backed cartridge seats in their resilient seated lines, which provide dimensional stability and prevent the seat from collapsing under vacuum or high-velocity conditions.

For engineers, DHC is often a strong candidate for auxiliary systems, plant water services, and applications where a heavy, custom-fabricated valve is unnecessary, but reliable isolation is required. Their focus is on the standard concentric, rubber-lined design that serves the vast majority of low-to-medium pressure HVAC and water applications.

Bray International

Bray International is a dominant force in the industrial and automation sectors, with a growing presence in municipal water and wastewater. Bray’s engineering DNA is distinct from the traditional “heavy iron” AWWA manufacturers; they excel in high-performance, modular, and automated solutions.

Bray is best known for two distinct lines: the resilient-seated Series 30/31 and the high-performance Series 40/41 (McCannalok). The Series 30/31 features a unique tongue-and-groove seat design that isolates the body entirely from the line media, allowing for the use of economical body materials while maintaining high corrosion resistance internally. The high-strength, through-stem design utilizes an internal double-D drive connection, eliminating the need for disc screws or taper pins which are common corrosion or failure points.

The Series 40/41 is a double offset (high performance) butterfly valve. This design cams the disc off the seat immediately upon opening, virtually eliminating friction and wear during travel. For wastewater engineers dealing with high-pressure aeration blowers or systems requiring modulation, Bray’s high-performance valves offer superior cycle life and control accuracy compared to standard concentric rubber-lined valves.

DeZURIK

DeZURIK is a heavyweight in the wastewater and pulp & paper industries, sectors known for difficult, abrasive, and clogging media. Consequently, their butterfly valve designs—specifically the BAW (Butterfly AWWA) and BHP (High Performance) series—are engineered with extreme durability in mind.

DeZURIK’s BAW series distinguishes itself with a focus on corrosion protection and robust shaft connections. They offer valve construction with sintered stainless steel bearings which provide a very low coefficient of friction and are chemically inert. A critical engineering feature is their disc design in relation to solids; DeZURIK valves are frequently specified in wastewater treatment because their streamlined discs reduce the potential for “ragging” or solid accumulation.

Furthermore, DeZURIK is a leader in the application of high-performance butterfly valves (BHP) for water service. Their designs feature a double-offset geometry and often utilize PTFE or metal seats. This makes them suitable for higher temperatures and pressures found in thermal hydrolysis processes or high-lift pump stations. Their focus on the “Total Cost of Ownership” often appeals to maintenance supervisors who prefer a valve that costs more upfront but requires zero intervention for decades.

VAG

VAG is a global powerhouse in valve manufacturing, with a particularly strong reputation in large dams, transmission mains, and high-pressure applications. In the US market, VAG is often associated with the engineering legacy of GA Industries.

The crown jewel of VAG’s butterfly valve portfolio is the EKN® Double Eccentric Butterfly Valve. The engineering behind the EKN series is focused on hydrodynamics and seat longevity. The double offset design ensures that the rubber seal on the disc completely releases from the body seat after just a few degrees of opening. This frictionless motion significantly reduces torque requirements and wear on the seal, making it ideal for frequent operation or modulation.

VAG also incorporates advanced welding and coating technologies, with fusion-bonded epoxy applied to completely encapsulated castings. For consulting engineers designing large-scale water transmission lines (36-inch and above), VAG offers unique solutions like internal locking devices and specialized hydraulic actuation systems that are integrated directly into the valve design for safety in surge conditions.

Application Fit Guidance

Matching the specific OEM strengths to the application is critical for system performance. The following breakdown assists engineers in aligning manufacturer capabilities with project requirements.

Municipal Water Distribution

Preferred OEMs: Henry Pratt, Crispin Valve, VAG.

For buried service and distribution vaults, adherence to AWWA C504 is the primary requirement. Henry Pratt and Crispin offer the most extensive experience with standard mechanical joint and flanged connections suited for this environment. VAG is the preferred choice for large-diameter transmission mains where pressure recovery and low head loss are paramount.

Municipal Wastewater Treatment

Preferred OEMs: DeZURIK, Henry Pratt.

Wastewater applications introduce solids, grit, and corrosive gases (H2S). DeZURIK’s heritage in handling fibrous materials and their robust bearing seals make them a top contender for sludge and raw sewage isolation. Pratt’s rubber-lined valves are also widely used in clarifier isolation and aeration basins, provided the seat material (typically EPDM or Buna-N) is carefully matched to the chemical exposure.

Industrial Water & Wastewater

Preferred OEMs: Bray International, DeZURIK.

Industrial environments often involve higher temperatures, aggressive chemicals, or the need for precise automation. Bray’s high-performance double offset valves and their ease of integration with pneumatic/electric actuators make them ideal for process skids and plant automation. DeZURIK’s high-performance lines are also standard in power and pulp/paper wastewater streams.

High-Pressure & Pump Control

Preferred OEMs: VAG, DeZURIK.

For pump discharge applications where check valve functionality might be combined with isolation, or where high pressure drops exist, the double-eccentric designs from VAG and DeZURIK provide the necessary mechanical advantage. These valves handle the dynamic torque of high-velocity flow better than standard concentric designs.

Engineer & Operator Considerations

Beyond selecting the OEM, the successful deployment of butterfly valves relies on proper specification, installation, and maintenance strategies. The following technical considerations are derived from field experience and failure analysis.

1. Installation Orientation and Solids

In wastewater or raw water applications containing suspended solids, the valve shaft should invariably be installed in the horizontal position. When a shaft is vertical, grit and solids tend to accumulate in the bottom bearing area, eventually scoring the shaft and destroying the seal. Horizontal mounting allows the flow to scour the bottom of the valve body, preventing accumulation. Engineers must explicitly detail this orientation in the P&ID and installation details.

2. Upstream and Downstream Piping

Butterfly valve discs protrude into the flow stream. Turbulence caused by elbows, tees, or pumps immediately upstream can cause uneven loading on the disc (flutter), leading to premature bearing failure and shaft fatigue. A general rule of thumb is to maintain at least 6 pipe diameters upstream and 4 diameters downstream of straight pipe. If this is not possible, the valve rating/safety factor must be increased, or the actuator sizing must be adjusted to account for increased dynamic torque.

3. Velocity and Seat Washout

Engineers must calculate the actual fluid velocity through the valve. While butterfly valves can handle high flows, velocities exceeding 16 ft/s (5 m/s) can cause “cold flow” or washout of bonded rubber seats if the valve is used for throttling. In high-velocity applications, mechanically retained seats or high-performance metal-seated valves are superior.

4. Actuator Sizing and Safety Factors

A common mistake in specification is relying solely on the valve manufacturer’s “seating torque.” Over time, rubber seats harden, and debris increases friction. Operators frequently encounter valves that cannot be cracked open because the actuator was sized without a sufficient safety factor for “aged” conditions. Specifications should require actuator sizing based on unseating torque at maximum differential pressure, plus a minimum 25% safety factor.

5. Spare Parts and Obsolescence

For critical isolation points, the ability to replace a seat in situ is a major operational advantage. Bonded-seat valves are essentially disposable in smaller sizes, but for 24-inch and larger valves, the cost of removal is prohibitive. Selecting an OEM like Pratt or DeZURIK that supports field-replaceable seat designs can save tens of thousands of dollars in maintenance costs over the valve’s life.

Conclusion

The selection of a butterfly valve OEM for water and wastewater applications is a decision that dictates the reliability of the system for decades. It is not merely a choice of brand, but a choice of engineering philosophy. Henry Pratt and Crispin Valve define the standard for general municipal compliance and potable water distribution. DeZURIK and VAG offer the heavy-duty engineering required for wastewater solids, high pressures, and critical isolation. Bray International bridges the gap between industrial performance and municipal automation, while DHC International provides essential standard solutions for general service.

For the consulting engineer and the utility manager, the “best” valve is not the one with the lowest purchase price, but the one that aligns mechanically with the specific challenges of the fluid media and the installation environment. By focusing on seat retention methods, shaft geometry, materials of construction, and reputable OEM support, utilities can ensure their infrastructure remains robust, efficient, and maintainable for the long term.