Dispersed Release DAF Technology: Revolutionizing Wastewater Treatment

Dispersed Air Flotation (DAF) is a water treatment process that clarifies wastewater by the removal of suspended matter such as oil, grease, or solids. The effectiveness of DAF relies on tiny air bubbles that attach to solid particles, increasing their buoyancy and causing them to rise to the water’s surface. This method is widely used in industrial wastewater treatment and is known for its efficiency and speed in separating contaminants from water.

Design principles of Dispersed Release DAF systems are crucial for maximizing treatment efficiency. These principles address the size of microbubbles, the rate of air dissolution under pressure, and the separation of clean water from floating solids. Implementing a Dispersed Release DAF system requires careful consideration of these factors to ensure optimal performance. The benefits of using DAF include improved water clarity, reduced chemical usage compared to conventional methods, and the ability to handle high contaminant loadings, making it a valuable tool in modern water treatment.

Key Takeaways

- Dispersed Release DAF is a treatment process that effectively removes suspended contaminants from wastewater.

- Design principles are vital for the efficiency of Dispersed Release DAF systems.

- DAF is advantageous for its improved water clarity and handling of high contaminant loads.

Overview of Dispersed Release DAF

Dispersed Release DAF (Distributed Autonomous Framework) is a concept tailored towards improving incident management within certain response frameworks. It essentially revolves around the strategic distribution and coordination of assets across dispersed locations. This model is leveraged for effective communication and rapid deployment of resources in emergency response situations.

Key Components:

- Rapid Response: Enables teams to assemble quickly and operate effectively with an expectancy of high performance.

- Coordination: Ensures efficient communication amongst stakeholders, even when resources are spread across varied locations.

- Resource Allocation: Focuses on the optimal distribution of resources, catering to the needs of a dispersed workforce.

With a Dispersed Release DAF, agencies like APHIS (Animal and Plant Health Inspection Service) aim to streamline their actions during emergencies, particularly those involving animal or plant health crises. Notifications and updates reach the relevant parties promptly, supporting a cohesive response despite the physical distances.

Implementation in Agencies:

- The APHIS framework advises roles and coordination to manage situations involving foreign animal diseases effectively, adapting a Dispersed Release DAF strategy to enable rapid and efficient emergency management.

By incorporating the Dispersed Release DAF approach, agencies are now more adept at handling large-scale incidents by utilizing a framework that promotes flexibility, expediency, and reliability, which are crucial elements for successful emergency response operations.

Design Principles for Dispersed Release DAF Systems

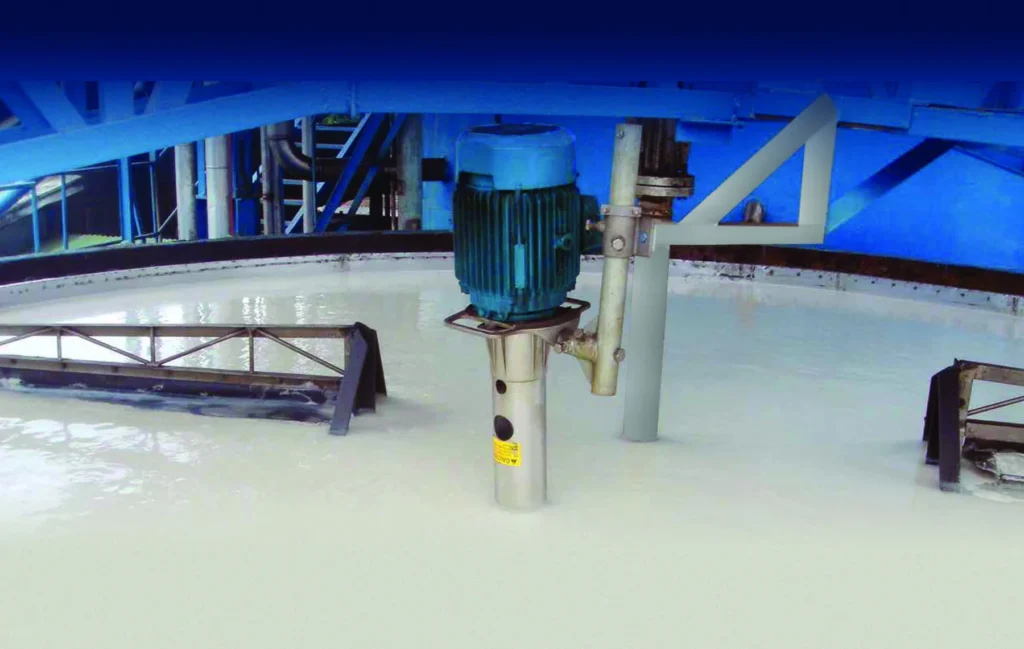

Dispersed Air Flotation (DAF) systems are critical in water treatment processes, particularly in separating fine particles and oils from wastewater. The design principles for Dispersed Release DAF systems are focused on efficiency, reliability, and compliance with environmental regulations.

Key Components

- Aeration system: It introduces air at high pressures to form microbubbles that attach to particles.

- Flotation tank: Serves as the setting for the effective separation of solids from the liquid.

- Skimmer mechanism: Essential for the removal of floated solids from the tank surface.

Operating Parameters

- Pressure: Maintaining proper pressure is crucial for the creation of microbubbles.

- Recycle rate: Adjusting the recycle rate impacts the contact between particles and bubbles.

- pH levels: Controlling the pH helps to optimize the flotation efficiency.

Construction Materials

The choice of construction materials should balance durability with cost-effectiveness, often including corrosion-resistant options like stainless steel or specialized plastics.

Optimization Strategies

- Utilize real-time monitoring to adjust operational parameters for peak performance.

- Regular maintenance schedules ensure system components function effectively.

- Control mechanisms should be in place to adapt to varying wastewater characteristics.

These principles highlight the importance of precision and adaptability in Dispersed Release DAF systems to meet the needs of modern wastewater treatment demands.

Benefits of Dispersed Release DAF

Dispersed Release Dissolved Air Flotation (DAF) systems offer clear advantages across several key areas. They are designed to enhance clarification efficiency for the separation of suspended solids and oil and grease in wastewater.

Environmental Benefits

Dispersed Release DAF systems are an eco-friendly solution to wastewater management. They reduce the need for harmful chemicals that are traditionally used in wastewater treatment, thereby diminishing the environmental footprint. These systems also promote water conservation by allowing higher rates of water recycling and reuse.

Economic Benefits

Economically, the adoption of Dispersed Release DAF technology can lead to significant cost savings. By optimizing water treatment processes, they reduce operational costs over time. This technology also minimizes sludge production which in turn lowers disposal costs. Through improved efficiency, industries can experience a decrease in both initial investment and long-term maintenance expenses associated with wastewater treatment.

Operational Efficiency

Operational efficiency is a hallmark of Dispersed Release DAF systems. They provide high-rate clarification and increased throughput in a compact design, resulting in a smaller footprint compared to conventional systems. Additionally, these systems are simple to operate and can adjust to varying feedwater conditions, ensuring steady performance and reliability.

Implementation Strategies

The successful implementation of Dispersed Release Dissolved Air Flotation (DAF) systems hinges on thorough planning, seamless integration into existing water treatment infrastructures, and meticulous adherence to regulatory standards.

Planning and Assessment

Initial Evaluation: Facilities must conduct a comprehensive assessment of their current water treatment capabilities and needs. The evaluation should consider the Dispersed Release DAF’s capacity to handle the expected influent load and its efficiency in removing solids.

Site-Specific Design: Each implementation strategy should be tailored to the unique characteristics of the site, ensuring that the Dispersed Release DAF system is customized to meet specific treatment goals effectively.

Integration with Existing Water Treatment

- Compatibility: Ensure that the Dispersed Release DAF system complements and enhances the existing water treatment processes, rather than causing disruptive changes or inefficiencies.

- Infrastructure Modifications: In some cases, facilities may require alterations to their current infrastructure to accommodate the Dispersed Release DAF system, which must be planned and executed with precision.

Compliance with Regulations

Local and Federal Regulations: Facilities must navigate a complex landscape of environmental regulations. The implementation of Dispersed Release DAF systems must comply with all pertinent legislation to avoid legal repercussions and ensure environmental protection.

Continuous Monitoring: The adoption of Dispersed Release DAF technology should include establishing protocols for regular monitoring and reporting to maintain compliance with regulatory standards over time.

Challenges and Considerations

In exploring the complexities of Dispersed Release Donor-Advised Funds (DAFs), stakeholders face a series of hurdles spanning technical, financial, and regulatory domains. Each category presents its unique set of issues, demanding careful navigation and strategic planning.

Technical Challenges

Technical challenges in the realm of Dispersed Release DAFs include ensuring secure, efficient distribution of funds to multiple charities. They must also maintain robust data systems for tracking the allocation and impact of those funds. Accurate reporting and data integrity are paramount, as they inform future grant-making decisions and ensure transparency.

- Data Security: Maintaining the confidentiality and integrity of donor information.

- Fund Allocation: Developing algorithms that ensure equitable and purposeful dispersal of funds.

Financial Considerations

When it comes to financial considerations, Dispersed Release DAFs must manage the balance between investment growth and charitable distribution. They also grapple with operational expenses that can impact the overall efficacy and appeal to potential donors.

- Investment Strategy: Choosing strategies that align with donors’ expectations for growth and charitable impact.

- Overhead Costs: Striving to minimize costs to maximize the amount directed toward charitable activities.

Regulatory Hurdles

Regulatory hurdles for Dispersed Release DAFs are not to be underestimated. Compliance with IRS rules regarding charitable giving and the ever-evolving tax laws concerning DAFs must be diligently followed to maintain tax-exempt status.

- IRS Compliance: Adhering to complex IRS regulations that govern DAF activities.

- Tax Law Changes: Staying abreast of and adapting to legislative amendments that affect donor contributions and tax benefits.

Case Studies

Dispersed Release DAF systems have been implemented across a variety of sectors, showcasing their efficacy in removing contaminants and suspended solids from wastewater. The case studies below illustrate their practical applications and outcomes.

Industrial Application: In one instance, a major food processing plant employed a Dispersed Release DAF system to treat its wastewater. Before implementing DAF, the facility struggled with high levels of organic waste. Post-installation, analyses indicated a significant reduction in Biological Oxygen Demand (BOD), with levels dropping by approximately 90%.

- Pre-DAF BOD levels: 3000 mg/L

- Post-DAF BOD levels: 300 mg/L

Municipal Wastewater Treatment: A city’s wastewater treatment plant integrated Dispersed Release DAF to manage the loads during peak periods. The system allowed for flexible operation with its ability to handle sudden increases in wastewater volume while maintaining compliance with environmental discharge regulations.

- Peak flow handling increase: 25%

- Compliance rate: 99.7%

Results in Oil and Wastewater Management: In the oil industry, the use of Dispersed Release DAF facilitated the separation of oil and suspended solids from produced water, enabling reuse or safer disposal of water. The system’s high efficiency in oil removal contributed to the plant’s overall cost savings by reducing the need for secondary treatments.

- Oil removal efficiency: >95%

- Cost savings: Estimated 20%

Each case study reinforces the Dispersed Release DAF’s versatility and efficiency across different scenarios. The adoption of this system can lead to substantial improvements in wastewater treatment processes, aligning with environmental standards while offering operational advantages.

Future Developments in DAF Technology

Dissolved Air Flotation (DAF) systems are integral to various industries, ranging from wastewater treatment to mining. Future developments in DAF technology point toward more efficient, automated, and environmentally friendly systems.

Efficiency Improvements

- Energy Usage: Advances aim to reduce the high energy demands of current systems.

- Dissolved Air System: Innovations in dissolved air production methods are anticipated to enhance microbubble generation.

Automation and Control

- Robotic monitoring systems are being integrated for real-time adjustments.

- Advanced sensors could allow for automated chemical dosing, optimizing the treatment process.

Environmental Impact

- Developers are focusing on minimizing chemical use, thereby reducing environmental footprints.

- Closed-loop systems are being designed to recycle processed water.

Cost Reduction

- Materials: Research is geared towards more cost-effective materials that maintain or enhance durability.

- Lifecycle: Increased system lifespan is a key goal, looking to decrease long-term operational costs.

Specialized Applications

- Tailoring DAF systems for specific industrial needs, such as selective removal of certain contaminants, is expected.

- Dispersed Release DAF could see advancements in targeted applications, such as the precise treatment of algal blooms in water bodies.

Technological advancements in DAF systems will likely continue to progress in ways that align with global sustainability goals and efficiency imperatives.

Conclusion

Dispersed Release DAF (Distributed Ambrosia Fuselage) technology represents a significant advancement in the field of aeronautics and dispersion methodologies.

Dispersed Release Mechanism: Dispersed Release DAF employs a streamlined release mechanism, significantly improving upon traditional systems.

- Durability: The design showcases enhanced durability against various stress factors.

- Efficiency: Operational efficiency has been a key focus, with metrics indicating a notable increase in effectiveness over previous models.

Integration with Existing Systems: The technology integrates seamlessly with existing frameworks, facilitating a smoother transition from older models to this state-of-the-art system.

- Compatibility: High compatibility with a range of systems and models.

- Upgrade Path: Offers a clear pathway for upgrading from legacy systems without the need for extensive overhauls.

In terms of deployment, entities utilizing Dispersed Release DAF experience fewer complications, leading to more predictable outcomes and sustained operation performance. This reliability translates into both time and cost savings for operators, who can depend on the technology to perform consistently under diverse conditions.

To conclude, Dispersed Release DAF stands as a testament to innovation and progress in its field, demonstrating an impressive blend of resilience, efficiency, and compatibility. Its adoption is a testament to its designers’ commitment to addressing the sophisticated needs of modern aeronautics.

Frequently Asked Questions

Can you provide examples of sustained-release drug formulations?

Sustained-release drug formulations are designed to release medication at a predetermined rate to maintain a constant drug concentration for a specific period. Examples include various oral tablet and capsule systems such as osmotic pressure-controlled release oral delivery systems (OROS), and matrix-based tablets which often incorporate hydrophilic polymers such as hydroxypropyl methylcellulose.

How is controlled release dosage formulated?

Controlled-release dosage formulations involve a precise design that ensures a medication is released gradually and at a uniform rate. The formulation strategies may involve encapsulating the drug in a polymer matrix or coating the dosage form with semi-permeable membranes. Techniques to achieve this include microencapsulation and employing biodegradable polymers that allow the drug to be released as the material breaks down.

In pharmaceutics, what are the distinctions between dissolution and dispersion processes?

Dissolution is a process where solid forms of the drug dissolve in a solvent, usually leading to the drug becoming available for absorption. Dispersion, on the other hand, involves the drug being distributed throughout a medium, which can be a solid, liquid, or gas. In the context of controlled release formulations, dissolution is often a rate-determining step in the release of the drug, while dispersion can refer to the distribution of the drug within the dosage form or the body.