Zone Settling in Wastewater Treatment Processes: Understanding the Mechanism

Zone settling is a crucial phase in the wastewater treatment process, which involves the separation of suspended solids from water. This process is based on the differential settling rates of particles under the influence of gravity. In the context of wastewater treatment, zone settling aids in concentrating the solid particles, thus enabling the removal of biological matter and other impurities that can compromise water quality. The effectiveness of this method plays a vital role in determining the efficiency of the entire wastewater treatment system.

The design and operation of zone settling facilities are complex tasks that require a deep understanding of various factors such as particle size distribution, sludge volume, and the dynamics of sedimentation. It is often integrated within secondary treatment processes where biological flocs or coagulated particles must be separated from the treated water before it undergoes further purification or is discharged. Careful control of operational parameters and regular performance evaluation are necessary to ensure compliance with environmental regulations and to achieve optimized treatment results.

Key Takeaways

- Zone settling is essential for removing suspended solids in wastewater treatment.

- Effective zone settling relies on well-designed processes that account for sedimentation dynamics.

- Regular monitoring and adherence to regulations are critical for optimal zone settling performance.

Fundamentals of Zone Settling

Zone settling plays a crucial role in the wastewater treatment process, ensuring the effective separation and removal of suspended solids from liquid effluents.

Definitions and Principles

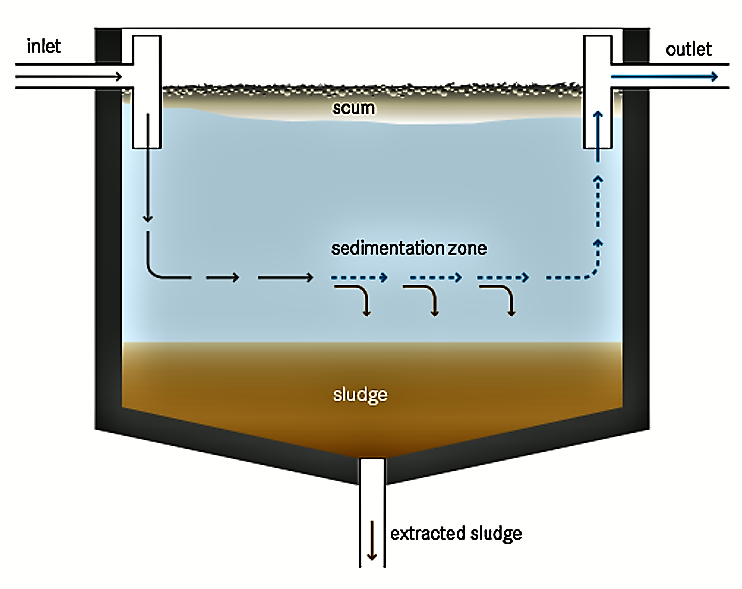

Zone settling refers to the physical process where particulate matter separates from a liquid and descends due to the force of gravity. In wastewater treatment, this principle is leveraged during the clarification phase, where solids gradually fall to the bottom of a settling tank, forming a concentrated sludge layer. This phenomenon occurs across distinct zones within the settler, each characterized by varying solids concentrations and settling velocities.

The Role of Gravity

Gravity is the key driving force in the process of zone settling. The gravitational pull causes denser particles within the wastewater to move downward, leaving clearer water above. The effectiveness of gravity-driven settling is governed by Stokes’ law, which relates the rate of fall to the density and size of the particles, as well as the viscosity of the liquid.

Importance of Solids Concentration

The dynamics of zone settling are significantly influenced by the concentration of solids in the wastewater. When solids are too dilute, settling can be slow and ineffective; conversely, when too concentrated, hindered settling might occur, reducing clarity. Optimal concentration is critical for maximizing efficiency, facilitating the formation of distinct zones where clear liquid separates from solid matter. This contributes to the formation of a blanket of sludge that is subsequently processed or removed.

Process Design

In wastewater treatment, the process design of zone settling is critical for ensuring efficient separation of solids from liquids. This section will detail the specific criteria required for designing a zone settling system and the various types of systems used in the industry.

Design Criteria

The design criteria for zone settling in wastewater focus on several key parameters that dictate efficiency and effectiveness. These include flow rate, solids concentration, detention time, temperature, and tank geometry. It is important to consider the expected influent characteristics such as Biological Oxygen Demand (BOD5), Total Suspended Solids (TSS), and pH levels. Furthermore, the design must accommodate peak flow conditions to prevent system overload. The sludge volume index (SVI) is a crucial parameter for analyzing the settling characteristics of the sludge, which directly impacts the design.

Types of Settling Systems

Zone settling systems in wastewater treatment can be categorized into different types based on their design and functionality. Primary clarification is one of the initial steps in the overall treatment process, designed to remove large solids through gravitational settling. On the other hand, secondary settling tanks are used for the sedimentation of bio flocs and other fine particles after biological treatment processes. Within these categories, designs can further vary, with some systems such as rectangular and circular clarifiers. The choice of system often depends on the spatial constraints of the treatment plant and the specific treatment requirements.

Operational Considerations

In wastewater treatment, zone settling is a critical phase where operational considerations dictate efficiency and effectiveness.

Flow Rates and Loading

Maintaining optimal flow rates is crucial to the zone settling process. It is necessary to achieve a balance, as higher rates can hinder settling by creating turbulence, while lower rates can lead to the settling of lighter particles and reduced capacity. Loading parameters should align with design specifications to prevent overloading which can lead to the escape of solids.

Temperature Effects

Temperature plays a significant role in the kinetics of zone settling. A higher temperature accelerates particle settling due to reduced water viscosity, whereas cooler temperatures slow it down. Operators must account for seasonal variations as they can affect settling characteristics and adjust operations accordingly.

Chemical Enhancement

Adding coagulants or flocculants to wastewater can enhance zone settling by aggregating fine particles into larger flocs. This chemical enhancement must be carefully controlled since overuse can cause excessive sludge volume and underuse may not provide the desired settling. Regular monitoring and dosage adjustments are imperative for optimal chemical application.

Performance Evaluation

Evaluating the performance of zone settling in wastewater treatment is essential for ensuring the efficiency and reliability of the sedimentation process. It involves regular monitoring and the ability to troubleshoot common issues that may arise.

Monitoring and Control

Monitoring: Effective performance evaluation begins with consistent monitoring of the settling characteristics of the wastewater. This typically includes measuring the settling velocity of particles within the zone settling region and ensuring that the sludge blanket does not rise to a level that would cause carryover into the effluent. Parameters such as influent and effluent suspended solids, sludge volume index (SVI), and return activated sludge (RAS) rates are tracked regularly.

Control Measures: Real-time control systems are implemented to adjust the wastewater treatment process in response to changes in the measured parameters. For instance, an increase in the inflow rate or load may necessitate adjustments in RAS rates or aeration times to maintain optimal zone settling conditions.

Troubleshooting Common Issues

Common Issues: Issues in zone settling can manifest as poor settling characteristics, such as high SVI, or a sludge blanket that rises too quickly.

Solutions: When these issues are identified, the following steps are taken:

- Adjusting RAS Rates: Managing the quantity of sludge recycled back to the aeration tank to ensure proper balance.

- pH Adjustments: Sometimes pH levels can affect settling; thus it’s crucial to monitor and adjust pH when needed.

- Aeration Control: Modifying the aeration to maintain oxygen levels that support flocculation and settling.

Troubleshooting is systematic and relies on data collected from the monitoring step to guide the necessary adjustments.

Regulations and Compliance

Zone settling in wastewater treatment processes is governed by stringent regulations to ensure environmental protection and public health. Adherence to these regulations is crucial for treatment facilities to maintain compliance and minimize the environmental impact of wastewater discharge.

Local and Federal Guidelines

Regulatory bodies at both local and federal levels set forth guidelines that dictate the acceptable parameters for zone settling in wastewater treatment. Local ordinances may vary based on regional environmental factors, but they typically align with federal regulations to form a comprehensive regulatory framework. For instance, the U.S. Environmental Protection Agency (EPA) oversees the National Pollutant Discharge Elimination System (NPDES), which mandates the proper management and treatment of pollutants, including the specific requirements for sedimentation processes such as zone settling. Facilities must obtain an NPDES permit and demonstrate compliance with the Clean Water Act to legally discharge treated wastewater into the waters of the United States.

- Permit Requirements: Facilities must adhere to specific zone settling metrics outlined in their NPDES permit.

- Monitoring and Reporting: Regular reporting on wastewater quality and sedimentation processes is essential for compliance.

Environmental Impact Considerations

The environmental impact of wastewater treatment, particularly zone settling, is a key focus of compliance regulations. These considerations ensure that the settling process adequately removes suspended solids and associated pollutants without harming aquatic ecosystems. Regulatory compliance not only encompasses the efficiency of solids removal but also includes the prevention of excess sludge accumulation, which can lead to adverse environmental consequences if not properly managed.

- Impact Mitigation: Facilities are required to implement measures that prevent excess sludge from impacting local waterways.

- Sustainability Practices: Adoption of best management practices, such as those found in the Best Management Practices (BMPs) Siting Tool, is encouraged to improve the sustainability of zone settling processes.

Throughout the zone settling process, facilities must regularly consult regulatory guidelines and demonstrate their compliance through effective wastewater treatment practices, continuous monitoring, and adherence to permit conditions.

Case Studies and Applications

Zone settling plays a critical role in the treatment of wastewater. This section explores practical applications in both municipal and industrial settings, illustrating the efficiency and adaptability of zone-settling processes in managing waste.

Municipal Wastewater Treatment

In municipal wastewater treatment, zone settling often occurs within secondary clarifiers after the activated sludge process. A notable case study involves the John E. Egan Wastewater Treatment Plant in Illinois, where upgrades to the settling tanks improved effluent quality and plant capacity. The implementation of Enhanced Settling Systems significantly increased the plant’s ability to handle high flow rates during storm events, leading to more effective settling and fewer instances of overflow.

Key Components:

- Clarifier Design: Upgrades to improve settling efficiency.

- Flow Management: Enhanced capacity to manage increased flow during wet weather.

Operational Benefits:

- Improved Effluent Quality: Clearer water discharged into receiving bodies.

- Increased Plant Capacity: Ability to treat higher volumes of wastewater without compromising effluent standards.

Environmental Impact:

- Reduced Overflow Events: Healthier aquatic ecosystems due to fewer discharges of untreated water.

Industrial Wastewater Scenarios

Industrial applications often demand specialized zone-settling techniques due to the diverse and complex nature of the waste. The Sequencing Batch Reactors (SBR) at XYZ Chemical Facility demonstrate successful adaptation to variable waste streams. The SBR system allows for precise control over the settling phase, which adapts to changes in the industrial process effluent.

Settling Challenges:

- Variable Waste Composition: Changes in the waste require flexible settling strategies.

- High Concentrations of Contaminants: Industrial waste may contain heavier organic and inorganic loads.

Solutions Implemented:

- Customized SBR: The design involves periodical settling and decanting, ensuring thorough treatment.

- Continuous Monitoring: The system adapts to real-time changes in waste composition, adjusting the settling phase as needed.

Industry-Specific Outcomes:

- Tailored Treatment: Achieved compliance with strict discharge regulations.

- Minimized Downtime: Reduced interruptions to industrial operations due to efficient waste management.

Advancements and Innovations

Zone settling in wastewater treatment has seen significant advancements and innovations aimed at improving efficiency and performance. The field benefits from continuous research and technological development, pushing the boundaries of what is possible in separation processes.

Emerging Technologies

In the realm of zone settling, advanced materials have been introduced for constructing settlers, which enable better sludge compaction and clearer effluent. For instance, the implementation of lamella plates, which increases the surface area, allows for a greater amount of solids to settle out by gravity, thereby enhancing the settling process within the same footprint.

Additionally, real-time monitoring systems have been integrated into zone settling processes, utilizing sensors and online instrumentation to provide immediate feedback on the quality of the settled effluent and the density of the sludge layer. These systems allow for precise control over the addition of coagulants and flocculants, improving the efficiency of the settling process.

Research and Development

Research in zone settling has focused on optimizing the various stages of the process, including flocculation, transportation, and clarification. Studies are examining the impact of factors such as flocculant type, dosing rates, and the aspects of hydraulic design on settling rates and effluent quality.

Recent developments in computational fluid dynamics (CFD) modeling offer insights into the flow patterns and solid-liquid separation mechanics, which can be used to design more effective settling tanks. This research is essential for developing next-generation zone settler designs, which aim to achieve higher capacities and better adapt to varying wastewater characteristics.

Conclusion

Zone settling plays a critical role in the wastewater treatment process. It is the phase where particles within the wastewater begin to settle out by gravity, leading to clearer effluents and reduction of pollutants. The efficiency of zone settling directly impacts the overall effectiveness and operational costs of a treatment facility.

The process is governed by factors such as particle size, density, and the viscosity of the wastewater. Consultants and engineers must carefully design settling tanks to ensure optimal conditions for the different zones of settling—discrete, flocculent, hindered, and compression—to function effectively.

Furthermore, the monitoring and regulation of this process are essential to mitigate potential issues like tank overloading or inefficient settling, which can lead to higher levels of suspended solids in the discharged water. Continuous research and advancement in technology can lead to improved methods for monitoring and managing zone settling in wastewater, thus ensuring compliance with environmental regulations and protecting natural water bodies from contamination.

In summary, the significance of zone settling in the realm of wastewater treatment is paramount, requiring attention to detail and constant supervision for sustaining water quality standards and ecological safety.

Frequently Asked Questions

How does zone settling differ from other sedimentation processes in wastewater treatment?

Zone settling in wastewater treatment is distinct because it involves a stratification process where solids settle at different rates, forming distinct layers or zones within a sedimentation tank, contrasting with uniform settling where particles descend at the same rate.

What are the key factors that influence the effectiveness of the settling zone in sedimentation tanks?

The effectiveness of the settling zone is significantly influenced by factors such as particle size and concentration, wastewater flow rate, and the design and dimensions of the sedimentation tank.

Can you describe the four distinct zones typically found within a settling tank and their specific functions?

A settling tank typically contains four zones: the clear zone at the top, where clarified water collects; the settling zone, where particles descend; the sludge zone at the bottom, where settled solids accumulate; and the thickening zone, where compaction of solids occurs.

In what ways does the inlet zone design impact the overall performance of a sedimentation tank?

The inlet zone design affects the distribution and flow of incoming wastewater, which is crucial to prevent disruptions in the settling process and to ensure uniform sedimentation across the tank.

What operational practices are essential to maintain the sludge zone in optimal conditions within a sedimentation tank?

To maintain optimal conditions in the sludge zone, routine sludge removal, monitoring sludge volume, and ensuring that the sludge has sufficient time to compact are essential practices.

How does the design of the outlet zone contribute to the quality of effluent in sedimentation basins?

The outlet zone's design contributes to the quality of effluent by allowing only the clear supernatant to exit, which minimizes the resuspension of settled solids and ensures the removal of high-quality clarified water from the tank.