Aqua-Aerobic vs Aero-Mod for Packaged Treatment Plants: Pros/Cons & Best-Fit Applications

INTRODUCTION

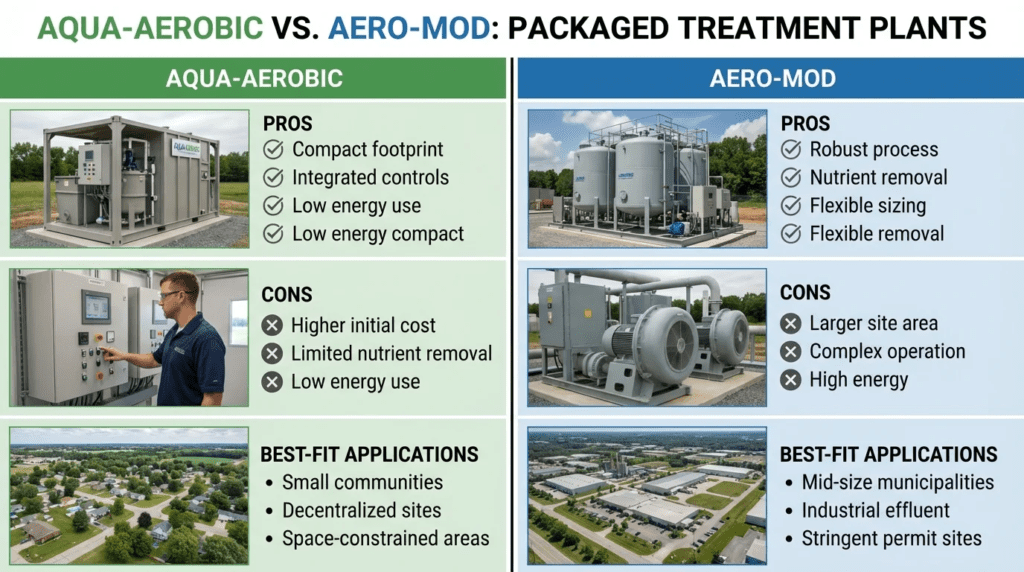

One of the most persistent debates in the small-to-medium wastewater treatment sector centers on the selection of sequencing batch reactor (SBR) technologies versus continuous flow loop variations. Specifically, when engineers evaluate Aqua-Aerobic vs Aero-Mod for Packaged Treatment Plants: Pros/Cons & Best-Fit Applications, they are essentially choosing between two distinct philosophies of hydraulic management and biological process control. A surprisingly high percentage of specifications in the 0.1 MGD to 5.0 MGD range default to whichever system the consulting firm used on their last project, rather than conducting a rigorous analysis of the specific site constraints and operator capabilities.

This oversight can lead to significant operational inefficiencies. While both manufacturers offer robust biological nutrient removal (BNR) capabilities, the mechanical means by which they achieve solid-liquid separation and the way they handle peak flow events differ fundamentally. Aqua-Aerobic Systems typically employs a true time-based SBR approach with mechanical floating decanters, whereas Aero-Mod utilizes a continuous-flow-like process (SEQUOX) with air-lift sludge management and a specialized clarifier zone (ClarAtor). Proper selection matters because the “wrong” choice for a specific application often manifests as chronic solids washout during wet weather events or excessive energy consumption during low-flow periods.

This article provides a technical, unbiased engineering analysis to assist municipal and industrial decision-makers in navigating the complexities of Aqua-Aerobic vs Aero-Mod for Packaged Treatment Plants: Pros/Cons & Best-Fit Applications. We will examine the hydraulic constraints, maintenance burdens, and lifecycle cost drivers that distinguish these two industry heavyweights.

HOW TO SELECT / SPECIFY

Selecting between these technologies requires moving beyond the brochure and analyzing the interaction between the plant’s hydraulic profile and the biological requirements. The following criteria should form the basis of the preliminary design report (PDR) and equipment specification.

Duty Conditions & Operating Envelope

The primary differentiator between these systems is how they manage hydraulic surges. Engineers must evaluate the flow peaking factor rigorously.

- Peaking Factors: True SBRs (Aqua-Aerobic) handle peaks by adjusting cycle times or utilizing a “storm cycle” mode where aeration is suspended to allow settling and decanting. This requires precise sizing of the tank volume to accommodate the surge without washing out solids. Aero-Mod systems typically operate with a constant level in the aeration basin and use a surge chamber or the clarifier volume to buffer flows, offering a hydraulic profile closer to continuous flow systems.

- Nutrient Targets: Both systems achieve excellent TN (Total Nitrogen) and TP (Total Phosphorus) removal. However, Aqua-Aerobic’s time-based phase management allows for infinite adjustability of anoxic/anaerobic durations via the PLC. Aero-Mod relies on spatial zones and selector basins. If the permit requires extremely low TP (< 0.1 mg/L) requiring multi-point chemical addition, the flexibility of the PLC-driven batch process may offer tighter control.

- Intermittent Flows: For applications like schools, resorts, or industrial parks where flow stops at night, the Aqua-Aerobic batch process is naturally suited to “idle” without short-circuiting.

Materials & Compatibility

Corrosion resistance is critical in packaged plants, especially if industrial contributors introduce aggressive influent.

- Tankage: Both manufacturers can retrofit into existing concrete basins or supply steel package plants. When specifying steel package plants, verify the coating specification (e.g., SSPC-SP10 near-white blast with high-solids epoxy).

- Internal Components: Aqua-Aerobic utilizes floating decanters and mixers. The materials for floats (fiberglass/stainless steel) and the flexible mooring cables are critical failure points if not specified correctly. Aero-Mod relies heavily on piping and air headers. The specification must dictate Schedule 40/80 PVC or Stainless Steel for air drops, particularly considering the thermal expansion caused by hot compressed air from the blowers.

Hydraulics & Process Performance

The hydraulic profile dictates the civil design and pumping requirements.

- Head Loss: Aero-Mod systems typically require less total dynamic head (TDH) change across the system compared to a variable-level SBR. Aqua-Aerobic systems operate with a variable water level (typically 3-5 feet of decant depth). This fluctuation must be accounted for in the influent pump sizing and the effluent hydraulic grade line.

- Decanting Mechanics: This is a major divergence point. Aqua-Aerobic uses a mechanical decanter that physically lowers into the clear liquid zone. This provides a positive barrier against scum but introduces moving parts. Aero-Mod typically uses hydraulic regulation and air-lift mechanisms to control flow, eliminating moving parts in the water but relying on precise air regulation to prevent solids carryover.

Installation Environment & Constructability

Site constraints often dictate the winning technology.

- Footprint: Aqua-Aerobic SBRs can be deeper, potentially saving surface area, but they require multiple basins for continuous inflow (or a headworks EQ). Aero-Mod’s ClarAtor design often integrates clarification within a rectangular footprint, which can be advantageous for retrofitting existing rectangular aeration basins.

- Electrical: Aqua-Aerobic systems are generally more instrumentation-heavy, requiring extensive conduit runs for decanter actuators, level transducers, and potentially dissolved oxygen (DO) probes per basin. Aero-Mod systems are mechanically simpler, often requiring fewer field electrical connections, as the primary control variable is air distribution.

Reliability, Redundancy & Failure Modes

Understanding how each system fails is crucial for risk management.

- Aqua-Aerobic: Reliability hinges on electromechanical components (actuators, winches, mixers). Redundancy requires spare actuators and mixers on the shelf. The PLC is the brain; if the PLC fails, manual operation is complex due to the timing requirements.

- Aero-Mod: Reliability hinges on the blower system. Since air drives sludge return and decanting (in some configurations), a total blower failure stops the biology and the hydraulics. Redundant blowers are non-negotiable. However, the lack of underwater moving parts significantly increases the Mean Time Between Failures (MTBF) for in-basin equipment.

Controls & Automation Interfaces

The complexity of the control system impacts operator requirements.

- SCADA Integration: Aqua-Aerobic provides a robust, pre-programmed PLC system (IntelliPro or similar). This offers deep data granularity but can be a “black box” that local integrators find difficult to modify.

- Control Philosophy: Aero-Mod logic is often simpler—based on timers and air valves. For smaller municipalities with limited instrumentation technicians, this simplicity is a significant advantage.

Maintainability, Safety & Access

- Water-Based Access: Maintaining a floating mixer or decanter on an Aqua-Aerobic system often requires a boat or a crane to lift the unit to the walkway. Engineers must specify davit crane sockets at strategic locations on the tank rim.

- Dry-Side Access: Aero-Mod maintenance is primarily focused on the blowers and air valves, located in a dry room or enclosure. In-basin maintenance (diffusers) typically requires tank drainage, which must be accounted for in the train redundancy design (e.g., can the plant meet permit with one train offline for cleaning?).

Lifecycle Cost Drivers

When analyzing Aqua-Aerobic vs Aero-Mod for Packaged Treatment Plants: Pros/Cons & Best-Fit Applications, the Total Cost of Ownership (TCO) often diverges from the capital cost.

- Energy: SBRs (Aqua) can optimize aeration energy by turning blowers off during settle/decant/idle phases. However, they may require larger blowers to meet oxygen demand during the shortened “react” window. Aero-Mod systems run blowers continuously (or on VFDs), but air is also used for pumping, which can be less efficient than mechanical pumps for RAS/WAS movement, though significantly lower maintenance.

- Spare Parts: Aqua-Aerobic will have higher long-term costs for actuator and mixer replacements. Aero-Mod will have costs associated with diffuser cleaning/replacement and potential air valve maintenance.

COMPARISON TABLES

The following tables provide a direct comparison to assist engineers in making objective specification decisions. These tables contrast the fundamental technology differences and application suitability.

Table 1: Technical & Operational Comparison

| Feature | Aqua-Aerobic (True SBR) | Aero-Mod (ClarAtor/SEQUOX) |

|---|---|---|

| Process Type | Time-based Batch Reactor (Fill, React, Settle, Decant) | Continuous/Sequencing Flow (Clarify-at-end) |

| Decanting Mechanism | Mechanical Floating Decanter (Actuated) | Hydraulic/Air-Lift Displacement (No moving parts in water) |

| Sludge Return (RAS) | Not typically required (Single tank reaction/settling) | Air-lift or Gravity (Process dependent) |

| Controls Complexity | High (PLC intensive, phase management) | Moderate (Timer/Air valve logic) |

| Hydraulic Profile | Variable Level (Requires upstream or in-tank EQ) | Constant Level (or near constant) |

| Primary Maintenance | Actuators, Floating Mixers, Decanter Seals | Blowers, Air Valves, Diffusers |

| Energy Strategy | Blower on/off cycling; batch aeration | Continuous aeration; air use for pumping |

| Typical Limitation | Mechanical complexity over water; peak flow management | Fixed clarifier geometry; dependency on air for hydraulics |

Table 2: Application Fit Matrix

| Scenario / Constraint | Aqua-Aerobic Fit | Aero-Mod Fit | Decision Criteria |

|---|---|---|---|

| Variable/Intermittent Flow | Excellent | Good | True batch mode handles “zero flow” periods better without short-circuiting. |

| Strict BNR (TN < 3, TP < 0.1) | Excellent | Very Good | PLC flexibility allows Aqua to tweak anoxic times easily; Aero-Mod requires proper selector sizing. |

| Low Operator Skill Level | Fair | Excellent | Aero-Mod’s lack of moving parts and simpler logic is more forgiving for part-time operators. |

| Existing Rectangular Tanks | Good | Excellent | Aero-Mod geometry fits easily into old activated sludge basins. |

| High Peak Wet Weather Flow | Requires upsizing | Good | Aero-Mod’s clarifier design generally handles hydraulic surges with less risk of washout than a batch decant cycle. |

| Limited Head Profile | Poor | Good | Aqua-Aerobic requires vertical depth for decanting; Aero-Mod operates with lower head loss. |

ENGINEER & OPERATOR FIELD NOTES

Beyond the catalog data, real-world experience dictates the success of these installations. The following notes are compiled from field observations regarding commissioning, O&M, and troubleshooting.

Commissioning & Acceptance Testing

When commissioning these systems, the Site Acceptance Test (SAT) is critical.

- For Aqua-Aerobic: Verify the “Storm Mode” logic. Simulate a high-level alarm input and confirm the PLC automatically shortens the cycle or switches to a settling-only phase. Visually inspect the decanter throughout its full travel range to ensure the flexible hose or knee-joint moves freely without kinking.

- For Aero-Mod: Focus on the air balance. The system relies on precise air distribution to different zones. Ensure that the air-lift pumps for sludge return are calibrated to the design flow rates and that the coarse bubble diffusers in the mixing zones are creating adequate turbulence without dead spots.

Common Specification Mistakes

One of the most frequent errors in specifying Aqua-Aerobic vs Aero-Mod for Packaged Treatment Plants: Pros/Cons & Best-Fit Applications is the neglect of scum removal.

- In SBRs, scum can accumulate during the settle phase. If the decanter does not have a scum exclusion mechanism (e.g., a sub-surface withdrawal or a scum guard), effluent quality will suffer.

- In Aero-Mod systems, the clarify-at-the-end design must have a robust surface skimming method. Engineers often undersize the airlift skimmers, leading to a “crust” forming on the clarifier surface.

O&M Burden & Strategy

Aqua-Aerobic Strategy:

The maintenance supervisor must implement a rigorous preventive maintenance (PM) schedule for the electromechanical actuators. These are the Achilles’ heel of the system.

Labor Estimate: 4-6 hours/week for mechanical inspection and sensor cleaning.

Aero-Mod Strategy:

The focus is on the blowers. Since the blowers run the hydraulics, their oil changes, belt tensioning, and filter changes are paramount.

Labor Estimate: 2-4 hours/week, mostly dry-side mechanical work.

Troubleshooting Guide

Symptom: High Solids in Effluent

- Aqua-Aerobic: Check the settling time. If sludge settles slowly (bulking), the decanter may be lowering into the sludge blanket. Solution: Increase settle time via PLC or increase WAS rate. Also, check for decanter seal leaks.

- Aero-Mod: Check the clarifier inlet velocity. If surges are too high, solids won’t settle. Check the RAS (Return Activated Sludge) rate; if the airlift is clogged, the clarifier will fill with solids and spill over.

DESIGN DETAILS / CALCULATIONS

Sizing Logic & Methodology

Proper sizing for these package plants follows standard Activated Sludge logic but with hydraulic modifiers.

1. Food to Microorganism Ratio (F/M)

Typical range: 0.05 to 0.15 lb BOD/lb MLSS/day for extended aeration/BNR.

- Aqua-Aerobic: Calculate based on the low water level volume, as this is the minimum reactive mass.

- Aero-Mod: Calculate based on the total aeration volume excluding the clarifier zone.

2. Hydraulic Retention Time (HRT)

Typical range: 18-24 hours for municipal wastewater.

- Aqua-Aerobic Calculation:

$$ V_{tank} = frac{Q_{daily} times HRT}{24} times frac{1}{Decant Ratio} $$

Note: The decant ratio (typically 30%) dictates that the tank must be ~30% larger than a flow-through tank to accommodate the batch volume.

Specification Checklist

When writing the spec, ensure these items are included:

- Oxygen Transfer Efficiency (OTE): Require independent verification of Alpha factors. Fine bubble diffusers in deep SBR tanks can achieve high OTE, but intermittent operation impacts membrane life.

- Blower Turndown: Blower packages must handle the minimum mixing air requirements versus the maximum design O2 demand. This often requires VFDs with a 4:1 turndown capability or multiple blower units.

- Material Certifications: For Aero-Mod, specify 304L or 316L stainless steel for all submerged air piping to prevent long-term corrosion.

Standards & Compliance

Both systems must meet the Ten States Standards (Great Lakes-Upper Mississippi River Board). Specifically regarding SBRs:

- Redundancy: A minimum of two basins (or trains) is required so that one can be taken offline for maintenance while the other handles the flow (potentially at reduced capacity).

- Scum Handling: Specific provisions for scum removal and disposal must be detailed.

FAQ SECTION

What is the primary difference between Aqua-Aerobic SBR and Aero-Mod systems?

The primary difference lies in the flow regime and mechanical complexity. Aqua-Aerobic utilizes a true batch process (SBR) with time-based phases and mechanical floating decanters. Aero-Mod utilizes a continuous-flow-like process (SEQUOX) with a distinct clarification zone (ClarAtor) and utilizes air-lift hydraulics to minimize moving parts within the tank.

Which system is better for nutrient removal (BNR)?

Both systems are highly capable of BNR. Aqua-Aerobic allows for greater operational flexibility because the anoxic and anaerobic phases can be adjusted via the PLC without physical modifications. Aero-Mod relies on physical selector zones; while effective, adjusting the retention time in these zones requires hydraulic manipulation. For applications with highly variable influent nutrient loads, Aqua-Aerobic’s time-based control often provides a slight edge.

How do the maintenance requirements differ?

Aqua-Aerobic systems require maintenance on electromechanical components located over the water (actuators, winches, floating mixers). This can present safety and access challenges. Aero-Mod systems concentrate maintenance on the dry-side blowers and valves. While Aero-Mod generally has fewer moving parts, diffuser maintenance requires tank drainage, whereas Aqua-Aerobic diffusers or mixers are often retrievable.

How does Aqua-Aerobic vs Aero-Mod for Packaged Treatment Plants compare in cost?

Typically, Aero-Mod may have a lower initial capital cost for the equipment package due to fewer actuators and sensors. However, civil costs must be factored in; Aqua-Aerobic SBRs can sometimes result in a smaller total footprint but deeper tanks. Operational costs (OPEX) depend on blower efficiency; Aqua-Aerobic can shut off blowers completely during settling, while Aero-Mod typically runs blowers continuously for hydraulic functions.

Can these systems handle high peak flows?

Aqua-Aerobic SBRs are volume-limited; high peak flows can force premature termination of settling phases, risking solids washout unless the tank is sized with significant freeboard. Aero-Mod systems act more like continuous flow plants with clarification zones, generally offering more hydraulic forgiveness during peak wet weather events.

Are these systems suitable for retrofitting existing plants?

Yes. Aero-Mod is particularly well-suited for retrofitting existing rectangular aeration basins due to its modular wall and piping layout. Aqua-Aerobic SBR equipment can be dropped into almost any basin shape, but the batch process requires verifying that the existing tank depth allows for sufficient decant volume.

CONCLUSION

KEY TAKEAWAYS

- Flow Profile: Choose Aqua-Aerobic (True SBR) for intermittent flows or strict batch control. Choose Aero-Mod for consistent flows or where hydraulic buffering is preferred.

- Maintenance Philosophy: Aqua-Aerobic = Electromechanical maintenance (actuators/PLC). Aero-Mod = Pneumatic/Blower maintenance.

- Simplicity: Aero-Mod offers “no moving parts in water,” ideal for plants with limited staffing. Aqua-Aerobic offers “PLC-driven flexibility,” ideal for plants requiring tight process adjustments.

- Constructability: Aero-Mod fits well in existing rectangular tanks. Aqua-Aerobic maximizes vertical depth usage.

- Reliability: Redundancy in blowers is critical for Aero-Mod. Redundancy in actuators is critical for Aqua-Aerobic.

In the final analysis of Aqua-Aerobic vs Aero-Mod for Packaged Treatment Plants: Pros/Cons & Best-Fit Applications, there is no single “winner”—only the best fit for the specific application. Engineers should avoid the trap of copy-pasting specifications from previous jobs.

If the project demands rigorous nutrient control with variable influent characteristics and the utility has a capable operator comfortable with SCADA systems, the Aqua-Aerobic SBR offers unmatched process control. However, if the priority is mechanical simplicity, minimizing in-basin maintenance, and providing a robust system for a small community with limited operator availability, the Aero-Mod solution often proves to be the superior lifecycle choice.

The most successful designs result from a transparent evaluation of the hydraulic profile (peaking factors) and an honest assessment of the end-user’s maintenance capabilities. By aligning the technology’s strengths with the utility’s realities, engineers can deliver a treatment plant that remains compliant and cost-effective for decades.