Mastering Centrifugation in Modern Water Treatment Solutions

Mastering Centrifugation in Modern Water Treatment Solutions

Introduction

Welcome to the world of centrifugation, where science meets efficiency in the quest for cleaner water! If you’re a municipal engineer, wastewater treatment operator, or just someone curious about how we keep our water systems running smoothly, you’re in for a treat. Think of centrifugation as the superhero of water treatment solutions spinning away impurities faster than a speeding bullet!

So, what exactly is this magical process? At its core, centrifugation leverages the power of centrifugal force to separate particles from liquids. Imagine you’re at a party, and everyone starts dancing. The heavier dancers let’s say the ones wearing those massive shoes are naturally going to gravitate towards the edges of the dance floor while lighter ones twirl in the center. That’s sedimentation in action!

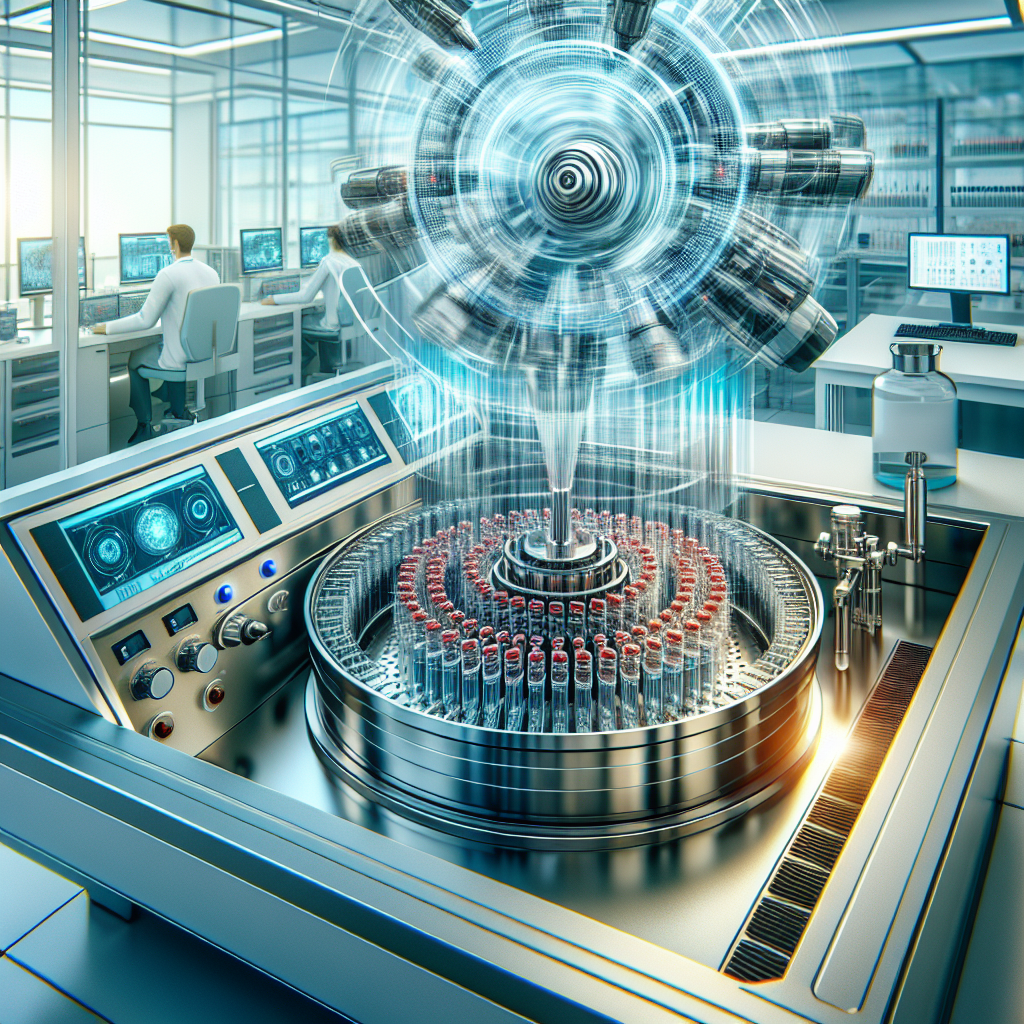

In modern water treatment, this principle is applied using various types of centrifuge machines that come equipped with different rotor types and speeds to optimize separation efficiency. From high-speed centrifuges used in industrial applications to compact benchtop models for clinical labs, each has its own unique role in ensuring our water is clean and safe.

But wait! Before you dive into the nitty-gritty of how these machines work (and trust me, it’s fascinating), let’s take a moment to appreciate their significance. Centrifugation isn’t just about separating solids from liquids; it’s about enhancing water quality, reducing waste, and making our treatment processes more efficient.

Did you know? The sedimentation rate can be significantly increased through optimized rotor speed and g-force settings in centrifuges. This means faster processing times and better quality outputs!

In this blog post, we’ll explore everything from the basic principles behind centrifugation to its various applications in modern wastewater treatment solutions. So buckle up as we embark on this scientific journey it’s going to be a wild ride!

Understanding Centrifugation

Centrifugation is like the superhero of the separation world, swooping in to rescue us from the clutches of unwanted particles and impurities. But what exactly is it? At its core, centrifugation is a process that uses centrifugal force to separate components in a mixture based on their density. Think of it as a high-speed dance party where heavier particles gravitate toward the dance floor (the bottom) while lighter ones float gracefully above them.

In the realm of water treatment, centrifugation plays a vital role. It helps municipalities and engineers efficiently remove solids from liquid waste, ensuring that our water sources remain clean and safe. The significance of this process cannot be overstated; without it, we’d be swimming in a pool of potential contaminants!

Key Benefits of Centrifugation:

- Effective separation of solids and liquids.

- Improved water quality for consumption and environmental discharge.

- Cost-effective solution for wastewater treatment facilities.

But wait, there’s more! The centrifuge machine itself is an engineering marvel. With various rotor types like swing bucket and fixed angle rotors, each designed for specific tasks, it’s no wonder that centrifuges have become indispensable tools in both laboratory and industrial settings.

You might be wondering about the different types of centrifugation techniques available. From ultracentrifugation used for separating biological macromolecules to differential centrifugation, which sorts out cellular components like some sort of biological sorting hat, there’s a method for nearly every application imaginable!

In summary, understanding centrifugation is crucial for anyone involved in water treatment solutions. It not only enhances operational efficiency but also contributes significantly to public health by ensuring cleaner water systems. So next time you think about water treatment processes, remember: it’s all about that spinning magic!

The Centrifuge Process

Centrifugation is like the superhero of water treatment, swooping in to save the day by separating out unwanted particles and impurities. But how does this magical process work? Let’s dive into the centrifuge process, shall we?

Basic Principles of Centrifugal Force

At its core, the centrifuge process relies on centrifugal force, which is generated when the centrifuge machine spins samples at high speeds. This force pushes denser materials outward, allowing them to settle at the bottom of the container a phenomenon known as sedimentation.

Key Components of a Centrifuge Machine

A centrifuge machine is made up of several key components that work together to achieve efficient separation:

- Rotor: The spinning heart of the centrifuge where samples are placed. Different rotor types, like swing bucket and fixed angle rotors, offer unique advantages depending on the application.

- Drive System: Powers the rotor and determines its speed (rpm). Higher speeds create greater g-forces, enhancing separation efficiency.

- Sample Tubes: Hold your samples during centrifugation. Balancing these tubes correctly is crucial for safe operation.

- Control Panel: The brain behind the operation, allowing users to set parameters like speed and time.

Centrifuge Uses in Water Treatment

The applications of centrifugation in water treatment are vast and varied. Here are just a few ways this powerful technique is employed:

- Sewage Treatment: Helps separate solids from liquids in wastewater processes, making it easier to treat effluents.

- Sludge Thickening: Concentrates sludge before further processing or disposal, reducing volume and improving efficiency.

- Microbial Separation: Used in laboratory settings for cell fractionation methods to isolate specific microorganisms from water samples.

- Turbidity Reduction: Removes suspended solids from drinking water sources to enhance clarity and safety.

Centrifugation can achieve sedimentation rates that are significantly faster than gravity alone, making it an indispensable tool in modern water treatment solutions!

Types of Centrifugation

Centrifugation isn’t just a single trick pony; it’s more like a whole circus of separation techniques! Each type of centrifugation serves its own purpose, tailored to specific applications. Let’s dive into the main types and see what makes each one special.

-

Laboratory Centrifuge vs. Industrial Centrifuge

Laboratory centrifuges are typically smaller and designed for precision tasks such as blood sample separation or cell fractionation methods. In contrast, industrial centrifuges are the heavyweights, used for large-scale operations in wastewater treatment and other industrial processes.

-

Ultracentrifugation and Its Applications

This technique spins samples at incredibly high speeds (think 100,000 rpm or more) to achieve maximum separation based on density. It’s often used in research labs for isolating cellular components or purifying proteins.

-

Differential Centrifugation Explained

This method separates particles based on their size and density by applying increasing centrifugal force. It’s like sorting your laundry: heavy items (pellets) sink first while lighter ones (supernatant) remain suspended.

-

Density Gradient Centrifugation Overview

In this technique, a gradient of density is created within the centrifuge tube. Particles will settle at their respective densities, allowing for precise separation perfect for isolating specific cell types or organelles!

-

Analytical vs. Preparative Centrifugation Methods

Analytical centrifugation is all about measurement think of it as taking the pulse of your samples to determine their characteristics. Preparative centrifugation, however, focuses on separating components for further use like extracting that sweet supernatant from your sample!

Understanding these types of centrifugation helps you select the right method for your specific needs whether you’re treating wastewater or conducting cutting-edge research!

Takeaway: Always choose the type of centrifugation that aligns with your project goals to maximize efficiency and effectiveness!

Centrifugal Force and Sedimentation Rate

When we talk about centrifugation, we’re diving into the fascinating world of centrifugal force and its pivotal role in sedimentation. Think of it like a roller coaster ride for particles in a liquid only instead of thrill-seekers, we have tiny solids and liquids trying to find their place in the world.

Centrifugal force is essentially the magic that makes this all happen. As the centrifuge machine spins, it generates a force that pushes denser materials outward, allowing them to settle at the bottom of the centrifuge tube, while lighter components remain suspended. This process is crucial for achieving effective separation in various applications, especially in water treatment.

Key Insight: The efficiency of separation largely depends on the sedimentation rate, which is influenced by several factors including particle size, shape, and density.

Understanding g-force in Centrifuges

The term “g-force” refers to the acceleration experienced by an object due to gravity. In our centrifuge context, it’s what helps separate those pesky particles from your sample. The higher the g-force, the more effective your separation will be. For instance, a high-speed centrifuge can generate forces exceeding 20,000 g!

The Relationship Between RPM and g-force

Now you might be wondering how this relates to RPM (revolutions per minute). The relationship between RPM and g-force is not linear; it’s actually exponential! As you increase the rotor speed (RPM), you’re ramping up that centrifugal force significantly. Here’s a little formula that can help you out:

g = (r × (RPM²)) / 1,118

Where “g” is the acceleration due to gravity (in units of g), “r” is the radius of the rotor in centimeters, and “RPM” is your rotor speed. So next time you’re calibrating your centrifuge machine, remember this formula it could save you from some serious sedimentation woes!

The Role of Rotor Speed in Separation Efficiency

The speed at which your rotor spins plays a critical role in how efficiently your samples separate. Fast rotor speeds lead to quicker sedimentation rates but can also introduce challenges like heat generation or sample degradation if not managed correctly. Different types of centrifugation techniques like differential or density gradient centrifugation exploit these differences effectively.

- High-Speed Centrifuges: Perfect for rapid separation but require careful monitoring.

- Refrigerated Centrifuges: Ideal for sensitive biological samples that need temperature control during processing.

- Benchtop Models: Great for smaller labs needing flexibility without sacrificing performance.

In conclusion, understanding how centrifugal force interacts with sedimentation rates can dramatically enhance your centrifugation processes in water treatment solutions. So buckle up those particles; it’s going to be a wild ride!

Centrifuge Components and Features

Understanding the centrifuge machine is like peeking under the hood of a high-performance vehicle. Each component plays a crucial role in ensuring that the centrifugation process runs smoothly and efficiently. Let’s break down the main features that make these machines tick.

Rotor Types: The Heart of Centrifugation

The rotor is arguably the most critical part of any centrifuge, as it determines how effectively samples are separated. There are two main types:

- Swing Bucket Rotor: This rotor swings outward during operation, allowing for a gentle separation process. It’s ideal for applications where sample integrity is paramount, such as in biological separation techniques.

- Fixed Angle Rotor: This rotor holds samples at a fixed angle, which can lead to faster sedimentation rates and higher efficiency. It’s great for applications requiring quick results, like blood sample separation.

Microcentrifuge Features

If you’re working with small volumes, you can’t overlook the microcentrifuge. These compact machines pack a punch with features tailored for high-speed operations:

- High Rotor Speeds: Microcentrifuges can achieve impressive g-forces, making them perfect for analytical centrifugation and cell fractionation methods.

- Versatile Accessories: Many come with interchangeable rotors to accommodate various tube sizes and types, enhancing their utility across different laboratory settings.

- User-Friendly Controls: Modern models often include digital displays and programmable settings to streamline operations.

The Benefits of Refrigerated Centrifuge Models

Centrifuging sensitive samples? A refrigerated centrifuge might be your best bet!

Refrigerated centrifuges maintain low temperatures during operation, preventing heat-induced damage to biological samples. This feature is particularly beneficial when dealing with proteins or nucleic acids that are sensitive to temperature fluctuations.

Centrifugal Force: The Driving Power

The power behind all this separation magic lies in centrifugal force. Understanding how g-force impacts your samples can help you optimize your centrifugation processes:

- The higher the g-force, the faster particles will sediment but balance is key! Overloading can lead to inefficiency or even equipment failure.

- A good rule of thumb: always consult your centrifuge’s manual for optimal settings based on sample type and desired outcomes.

Centrifuge technology continues to evolve, offering new features that enhance performance while ensuring safety and efficiency in water treatment solutions. By understanding these components and their applications, operators can harness the full potential of centrifugation in their processes.

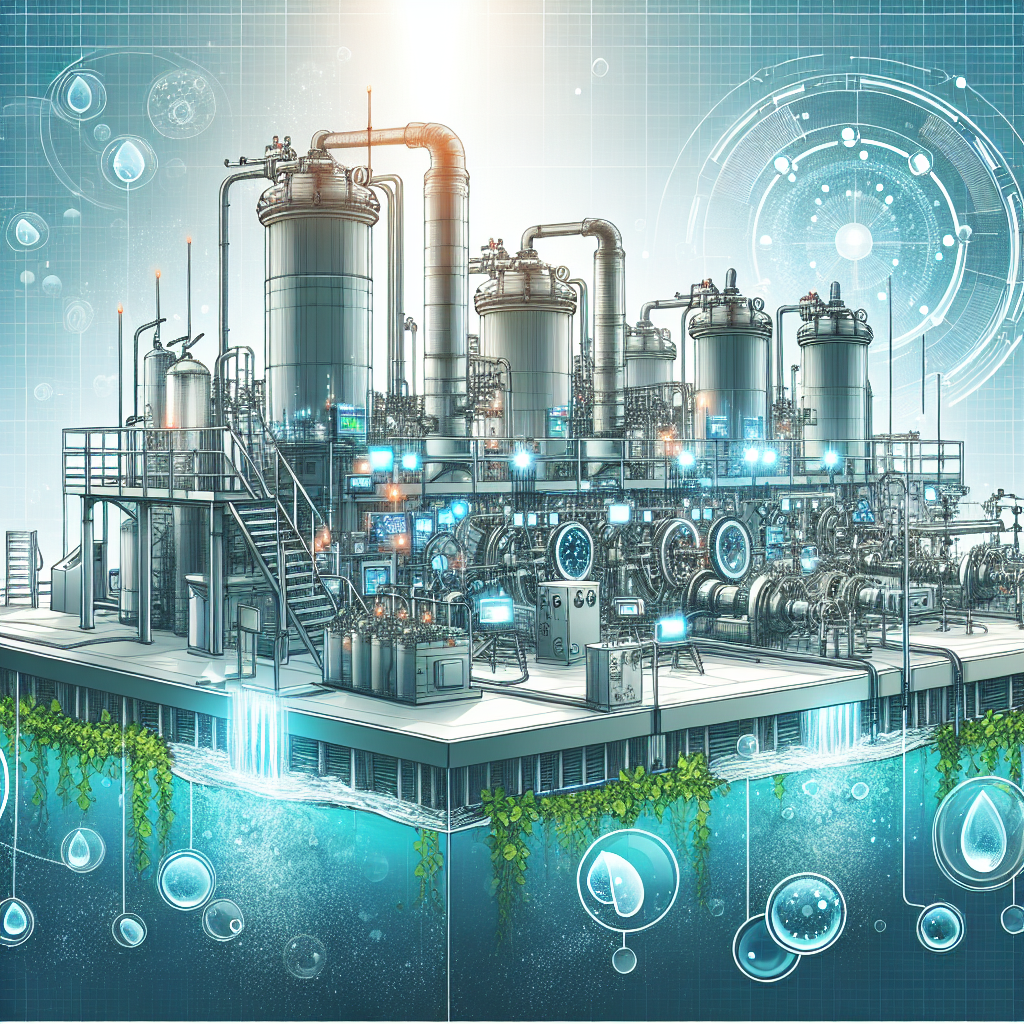

Centrifugal Separation Applications in Water Treatment

Centrifugation is not just a fancy word for spinning things around; it’s a powerhouse technique in the realm of water treatment. Let’s dive into how this biological separation technique works wonders for our water supply and wastewater management.

- Industrial centrifugation applications in wastewater treatment: In wastewater treatment plants, centrifuges play a pivotal role in separating solids from liquids. They effectively reduce the volume of sludge, making disposal easier and more efficient. Think of it as the ultimate spin cycle for your dirty laundry, but instead, we’re talking about dirty water!

- Clinical lab centrifuges usage guide for water quality testing: Centrifuge machines are also employed in laboratories to analyze water samples. By using high-speed centrifuges, technicians can quickly separate contaminants from clean water, ensuring that what flows from our taps is safe to drink. This process often involves blood sample separation techniques adapted for environmental testing talk about versatility!

Key Takeaway: The efficiency of centrifugal separation not only enhances the quality of treated water but also optimizes operational costs in both industrial and clinical settings.

The beauty of centrifugation lies in its adaptability across various types of operations from small-scale laboratory setups to large industrial applications. For instance, while a laboratory centrifuge might spin at lower rotor speeds to achieve precise analytical results, industrial models crank up the g-force to handle larger volumes with ease.

As we continue to face challenges like population growth and climate change, embracing advanced centrifugation methods will be crucial for sustainable water treatment solutions. Whether it’s through improving sedimentation rates or refining the separation process, the future looks bright (and clean) thanks to these spinning wonders!

- < li >Industrial centrifugation applications in wastewater treatment< / li >< li >Clinical lab centrifuges usage guide for water quality testing< / li >< / ul > section >