Top 10 Gravity Belt Thickeners Manufacturers for Water and Wastewater

Introduction

In municipal and industrial wastewater treatment, volume reduction is the single most effective method for controlling downstream costs. By thickening Waste Activated Sludge (WAS) from a typical 0.5–1.0% solids concentration to 5–7%, facilities can reduce the hydraulic volume sent to digesters or holding tanks by up to 85%. However, selecting the right equipment to achieve this is often oversimplified. Engineers frequently default to “same as last time” specifications, ignoring advancements in hydraulic loading capabilities and polymer efficiency. This article provides a technical analysis of the Top 10 Gravity Belt Thickeners Manufacturers for Water and Wastewater to assist in rigorous specification and procurement.

Gravity Belt Thickeners (GBTs) operate in a uniquely challenging environment. They must bridge the gap between high-volume, low-solids hydraulic flow and the viscous, abrasive nature of thickened sludge. The consequences of poor selection are immediate and costly: blinding belts, excessive polymer consumption (often the highest O&M line item), and inability to meet solids capture targets, which recirculates fines back into the plant headworks. Furthermore, the mechanical integrity of the frame and bearing systems determines whether the unit lasts 5 years or 25 years in a corrosive, hydrogen sulfide-rich atmosphere.

This guide is written for consulting engineers and plant operations staff. It moves beyond sales brochures to focus on the engineering physics, material selection, and operational realities that differentiate the Top 10 Gravity Belt Thickeners Manufacturers for Water and Wastewater. We will examine how to specify these units for reliability, how to evaluate manufacturer claims, and how to avoid the common pitfalls that plague thickening projects.

How to Select / Specify

Specifying a GBT requires balancing two distinct loading rates—hydraulic and solids—against the specific rheology of the sludge. While the Top 10 Gravity Belt Thickeners Manufacturers for Water and Wastewater all produce functional equipment, their design philosophies regarding frame rigidity, drainage area, and mixing energy differ significantly.

Duty Conditions & Operating Envelope

The first step in specification is defining the operating envelope. GBTs are generally rated based on belt width (typically 1.0 to 3.0 meters). However, sizing based solely on belt width is a recipe for failure.

- Hydraulic Loading Rate (HLR): This is often the limiting factor for thin sludges (WAS < 0.8%). Typical rates range from 100 to 250 gpm per meter of belt width. Exceeding this leads to sludge overflowing the side seals or blinding the belt due to rapid initial drainage.

- Solids Loading Rate (SLR): For thicker feeds, SLR governs. Typical capacities are 500 to 1,500 lbs dry solids per hour per meter. If the SLR is too high, the cake depth prevents water from draining through the belt, regardless of belt speed.

- Variability: Designs must account for diurnal flow peaks and seasonal changes in Sludge Volume Index (SVI). A GBT sized for average flow may be overwhelmed during wasting events.

Materials & Compatibility

Wastewater environments are inherently corrosive. The headspace above a thickener is often saturated with aerosols and H2S.

- Frame Construction: Specifications should mandate AISI 304 or 316 Stainless Steel for all wetted parts and structural frames. While hot-dip galvanized steel is cheaper, it rarely survives the 20-year design life in enclosed thickening rooms.

- Fasteners: Require 316 Stainless Steel for all fasteners to prevent seizing during maintenance.

- Rollers: Rollers should be rubber-coated or stainless steel. Deflection under load must be calculated to ensure belt tracking remains stable. A maximum deflection of L/1000 at full tension is a common engineering standard.

Hydraulics & Process Performance

The efficiency of a GBT is determined before the sludge hits the belt. The polymer injection and mixing system is critical.

- Mixing Energy: High-performance units utilize variable-orifice mixing valves or dynamic mixers rather than static mixers. This allows operators to adjust mixing energy (G-value) in response to changing sludge characteristics without changing flow rates.

- Retention Time: The length of the “feed box” or flocculation tank affects floc formation. Longer retention times allow for larger, stronger flocs that drain faster.

- Plow/Chicane Design: As sludge thickens along the belt, water gets trapped on top. Rows of plows or chicanes furrow the sludge, opening channels for free water to drain. Specifications should require adjustable plow angles and abrasion-resistant tips.

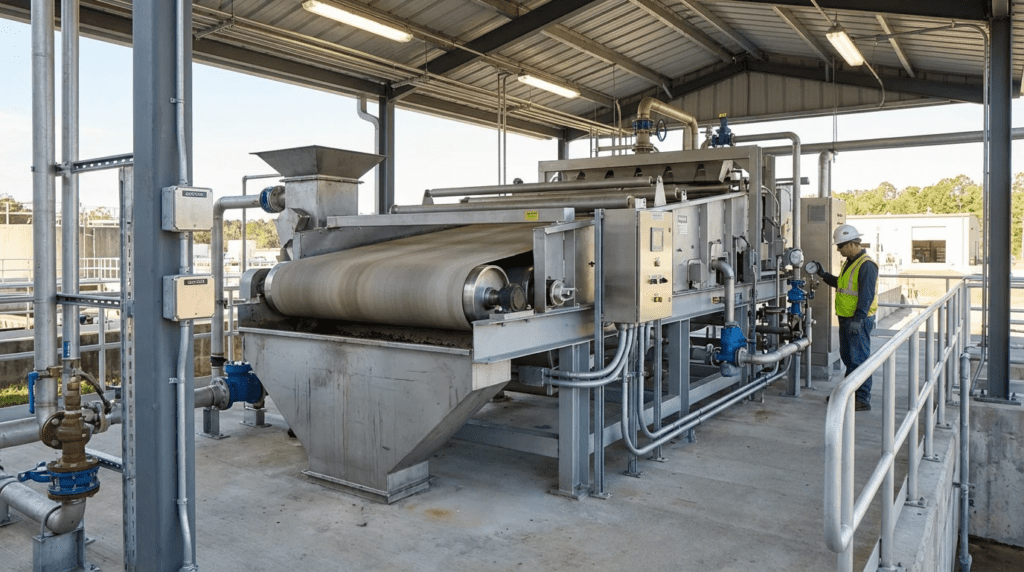

Installation Environment & Constructability

Physical constraints often dictate the choice among the Top 10 Gravity Belt Thickeners Manufacturers for Water and Wastewater.

- Enclosures: For odor control, fully enclosed units are becoming standard. Ensure the enclosure allows visual inspection (large polycarbonate windows) and easy removal of panels for belt changes.

- Drainage: GBTs generate significant washwater mist and filtrate. Floors must be sloped (min 1/4 inch per foot) to large trench drains.

- Access: A minimum of 3 feet of clearance is required around the unit, but 5 feet is recommended at the drive end for motor removal.

Reliability, Redundancy & Failure Modes

Reliability centers on the moving parts: bearings and belts.

- Bearing Protection: Bearings should be mounted externally to the frame, separated by a spacer or lantern ring, to prevent sludge ingress if a seal fails. Look for L-10 bearing life ratings exceeding 100,000 hours.

- Belt Tracking: Pneumatic tracking is common but requires clean, dry instrument air. Hydraulic tracking is more robust but introduces oil leak risks. The specification must define the preferred sensing mechanism (paddle vs. non-contact sensor).

Controls & Automation Interfaces

Modern GBTs are not “set and forget.” Integration with SCADA is essential for polymer optimization.

- Feed Forward Control: Flow meters on the sludge feed should pace the polymer dosing pump.

- Solids Sensors: While difficult to maintain, inline percent-solids sensors on the feed can effectively trim polymer dosing to prevent overdosing.

- Safety Interlocks: Critical interlocks include low washwater pressure, belt misalignment, emergency pull cords, and drive motor overload.

Lifecycle Cost Drivers

Engineers must educate clients that CAPEX is a fraction of the total cost of ownership (TCO).

- Polymer Consumption: A machine that requires 15 lbs of active polymer per dry ton versus one that requires 10 lbs/ton will cost hundreds of thousands more to operate over 20 years.

- Capture Rate: A 90% capture rate returns 10% of solids to the headworks. This recirculating load increases aeration costs and effectively reduces plant capacity. High-performance GBTs target >95% (often >98%) capture.

Comparison Tables

The following tables provide an engineering comparison of the leading manufacturers and technology applications. These are not rankings but rather a guide to understanding the diverse approaches within the Top 10 Gravity Belt Thickeners Manufacturers for Water and Wastewater. Note that “Series” names change; verify current model numbers with representatives.

| Manufacturer | Primary Engineering Strengths | Typical Applications | Limitations / Considerations | Maintenance Profile |

|---|---|---|---|---|

| Alfa Laval | Integrated automation; extremely compact designs; global support network. | Municipal plants with limited space; projects requiring high-level SCADA integration. | Higher initial CAPEX; proprietary parts can be costly. | Low maintenance frequency due to sealed designs, but specialized technician often required for major repairs. |

| Andritz | Heavy-duty industrial scale; high hydraulic throughput capacity. | Large municipal plants (>20 MGD); industrial pulp/paper applications. | Large footprint; may be overkill for small rural facilities. | Robust components designed for 24/7 continuous duty; straightforward mechanics. |

| BDP Industries | US-manufactured; exceptionally rigid frame construction; highly customizable. | Municipal retrofits; plants requiring specific dimensional customization. | Lead times can vary based on custom engineering requirements. | Excellent maintenance access; uses standard non-proprietary bearings and motors where possible. |

| Bellmer | German engineering focus on energy efficiency and polymer economy. | Plants with strict OPEX budgets; high-strength waste streams. | North American parts availability should be verified for specific regions. | Designed for ease of belt replacement; “Turbo” series offers high drainage rates. |

| Charter Machine Company | Simplicity; operator-centric design; “no-frills” durability. | Small to mid-sized municipalities; operators with limited automation support. | Less focus on advanced proprietary automation packages. | Very high operator favorability due to easy access and standard components. |

| Huber Technology | Fully enclosed stainless steel designs; focus on odor control and operator hygiene. | Indoor installations near residential areas; plants with strict odor constraints. | Enclosed design can make quick visual checks harder without opening hatches. | Integrated cleaning systems reduce manual washdown requirements. |

| Komline-Sanderson | Legacy reliability; massive installed base; conservative engineering ratings. | Conservative municipal specs; upgrades to existing K-S installations. | Traditional designs may lack some modern quick-release features of newer competitors. | Known for extremely long service life (20+ years) with routine bearing/belt care. |

| Ovivo (Eimco) | Process expertise; strong integration with overall plant flowsheet. | Greenfield plants where thickener is part of a larger Ovivo treatment train. | Best value realized when purchased as part of a package. | Standardized maintenance procedures; good technical manual documentation. |

| Parkson | Thickech Rotary Drum typically, but offers GBT solutions; focus on capture efficiency. | Plants needing extremely high capture rates to protect downstream processes. | Specific focus on rheology testing prior to installation. | Requires precise belt tensioning protocols to maintain capture performance. |

| Phoenix Process Equipment | Split-frame designs for easy belt changes; aggressive dewatering focus. | Mining and heavy industrial wastewater, as well as municipal. | Industrial focus means rugged finish rather than architectural aesthetics. | Cantilevered design options simplify belt installation significantly (reducing labor hours). |

| Application Scenario | Recommended Configuration | Key Constraint | Operator Skill Impact | Relative Cost Driver |

|---|---|---|---|---|

| Small Muni (< 1 MGD) | 1.0m width, manual polymer control, open or semi-enclosed. | Simplicity & Budget | High (Manual adjustment required) | Labor (O&M) |

| Large Muni (> 20 MGD) | 2.0m – 3.0m width, fully automated polymer/feed, enclosed. | Throughput & Reliability | Low (Automated) | Polymer & Energy |

| Odor Sensitive Area | Fully enclosed stainless steel with negative pressure ducting. | Odor Emissions | Medium | CAPEX (Enclosure) |

| High Grease/Oil (FOG) | High-pressure hot water wash system; aggressive plow design. | Belt Blinding | High (Frequent cleaning) | Washwater Heating |

Engineer & Operator Field Notes

The success of a gravity belt thickener project is rarely determined by the brand alone; it is determined by the integration of the machine into the process. The following notes are derived from commissioning and operational experience with the Top 10 Gravity Belt Thickeners Manufacturers for Water and Wastewater.

Commissioning & Acceptance Testing

Commissioning is the phase where theory meets reality. A rigorous plan is essential.

- Hydraulic Stress Test: Before introducing sludge, run the unit with water at maximum hydraulic capacity to verify seal integrity and drainage plumbing. Drain lines are frequently undersized in design, causing backups onto the floor.

- Polymer Optimization: Do not accept the “standard” dose. Require the manufacturer to perform a jar test series and a ramping trial on the full-scale machine to find the optimal G-value (mixing energy) and dose curve.

- Belt Tracking Verification: Simulate a tracking failure by manually pushing the tracking paddle. Verify that the belt corrects itself smoothly without “hunting” (oscillating back and forth) and that the emergency over-travel switch kills the motor instantly if the belt goes too far.

Common Specification Mistakes

- Ignoring Washwater Pressure: GBTs require high pressure (80-100 psi) but relatively low flow for the spray bars. Plant water systems often fluctuate. A dedicated booster pump per GBT (or per pair) is mandatory for reliable operation.

- Missing Filtrate Sampling: Engineers often forget to specify sample ports on the filtrate drain line. Without this, measuring solids capture efficiency requires dangerous confined space entry or guesswork.

O&M Burden & Strategy

Operational strategy shifts from “fixing” to “maintaining” with proper scheduling.

- Belt Cleaning: The spray bar is the heart of the GBT. If nozzles clog, the belt blinds, and sludge washes over the sides. Operators should rotate the handwheel on self-cleaning brush headers once per shift.

- Doctor Blade Inspection: The doctor blade (discharge blade) removes the thickened cake. If it becomes nicked or warped, it will streak sludge onto the return belt, fouling the washbox and rollers. Inspect weekly; replace annually or as needed.

- Labor Estimates: A typical GBT requires approximately 0.5 to 1.0 operator hours per shift for startup, shutdown, and visual inspection, assuming automated polymer systems are functioning correctly.

Troubleshooting Guide

Symptom: Sludge spilling off the sides of the belt (Pooping).

- Cause 1: Hydraulic loading too high. (Check flow meter).

- Cause 2: Polymer dose too low or mixing energy insufficient (floc is weak and water isn’t draining).

- Cause 3: Belt is blinded (Check spray wash pressure and nozzle status).

- Cause 4: Plows are blocking flow rather than furrowing (Adjust plow angle).

Symptom: Low thickened solids concentration.

- Cause 1: Belt speed too high (Sludge not on the table long enough).

- Cause 2: Feed concentration dropped (Check WAS pumps).

- Cause 3: Ramp/Dam height too low (Sludge exiting too quickly).

Design Details / Calculations

Proper sizing protects the engineer from liability and ensures the plant meets its solids handling goals.

Sizing Logic & Methodology

Never rely on a single parameter. Size for the worst-case scenario (typically Maximum Month loading or thinning due to seasonal turnover).

- Determine Design Loading: Calculate total dry solids (lbs/day) and total volume (gallons/day). Convert to max hourly rates based on the planned operating schedule (e.g., 6 hours/day vs. 24 hours/day).

- Check Hydraulic Loading Rate (HLR):

HLR = Flow (gpm) / Belt Width (m)

Limit to 200-250 gpm/m for WAS. - Check Solids Loading Rate (SLR):

SLR = Dry Solids (lbs/hr) / Belt Width (m)

Limit to 1,000-1,200 lbs/hr/m for typical municipal WAS. - Select Width: Choose the belt width that satisfies both criteria. Usually, WAS is hydraulically limited, while digested sludge is solids limited.

Specification Checklist

- Active Gravity Zone Area: Specify the minimum effective drainage area in square feet or square meters. This prevents manufacturers from supplying short units.

- Drive System: Variable Frequency Drive (VFD) is mandatory. Belt speed adjustment is the primary operator control variable.

- Polymer System: Specify a “neat” polymer pump and a programmable water dilution system. Aging polymer activates differently; flexibility is key.

- Standards:

- ANSI/B11.19 for machine guarding.

- NEMA 4X (Type 316 SS) for all local control panels and junction boxes.

- AWWA standards for wastewater treatment equipment (general applicability).

Frequently Asked Questions (FAQ)

What is the difference between a Gravity Belt Thickener and a Belt Filter Press?

A Gravity Belt Thickener (GBT) is used to thicken sludge (e.g., from 1% to 6%) to reduce volume before digestion or storage. It relies solely on gravity drainage through a porous belt. A Belt Filter Press (BFP) includes a gravity zone (similar to a GBT) but follows it with a wedge zone and a high-pressure zone where sludge is squeezed between two belts to produce a dewatered cake (typically 18-25% solids) suitable for landfill or incineration. GBTs pumpable product; BFPs produce solid cake.

How do you select the right belt mesh for the Top 10 Gravity Belt Thickeners?

Belt selection is a trade-off between capture efficiency and drainage rate. A tighter weave captures more solids (higher capture rate) but drains slower (lower hydraulic capacity) and blinds more easily. A more open weave handles high flow but may allow fines to pass through. Standard municipal WAS applications typically use a belt with air permeability around 300-450 CFM. Pilot testing or using a “test leaf” device is the best way to confirm mesh selection.

What is the typical lifespan of a Gravity Belt Thickener?

A well-specified GBT constructed of 304 or 316 stainless steel should last 20 to 25 years structurally. However, wear parts have shorter cycles: belts typically last 2,000 to 4,000 operating hours; seals and doctor blades last 1-2 years; and rollers/bearings typically last 7-10 years depending on maintenance quality and environment. The manufacturers listed in the Top 10 Gravity Belt Thickeners Manufacturers for Water and Wastewater are generally known for supporting this lifespan.

How much polymer does a Gravity Belt Thickener consume?

Polymer consumption varies by sludge type. For Waste Activated Sludge (WAS), typical active polymer dosage ranges from 8 to 15 pounds per dry ton of solids. For anaerobically digested sludge, it may range from 15 to 25 pounds per dry ton. Consumption is heavily influenced by the mixing energy (G-value) applied and the quality of the polymer make-down system. Over-dosing polymer can blind the belt, actually reducing performance.

Why is my Gravity Belt Thickener capture rate low?

Low capture rate (below 90-95%) usually indicates one of three issues: (1) The belt weave is too open for the particle size of the sludge; (2) The polymer dose is insufficient or the polymer type is incorrect (wrong charge/molecular weight), preventing strong floc formation; or (3) The hydraulic loading is too high, forcing sludge through the belt mesh rather than allowing gentle drainage. Verify the filtrate quality to diagnose the issue.

Conclusion

- Volume Reduction is King: GBTs are the most cost-effective way to reduce downstream hydraulic load.

- Size for Hydraulics and Solids: Do not size on belt width alone. Verify both Hydraulic Loading Rate (gpm/m) and Solids Loading Rate (lbs/hr/m).

- Material Matters: In H2S environments, 304 or 316 Stainless Steel is mandatory for longevity.

- Polymer is the Hidden Cost: A cheap machine with poor mixing can cost double its purchase price in wasted polymer over 5 years.

- Spec the Auxiliaries: Washwater booster pumps, proper ventilation, and easy-access platforms are as important as the thickener itself.

Selecting from the Top 10 Gravity Belt Thickeners Manufacturers for Water and Wastewater is not simply a matter of finding the lowest capital cost. It is an engineering exercise in matching mechanical capability with process reality. The best equipment in the world will fail if applied to a hydraulic load it cannot drain or a sludge type it cannot flocculate.

Engineers should focus their specifications on robustness—frame rigidity, bearing protection, and stainless steel construction—while ensuring the process design allows for operational flexibility. The ability to adjust ramp angles, plow configurations, and mixing energy ensures that the GBT can adapt to the inevitable changes in influent wastewater characteristics over the next two decades. By adhering to strict selection criteria and understanding the nuances of the manufacturers listed above, utilities can secure reliable, efficient thickening performance that protects downstream processes and minimizes total lifecycle costs.