Choosing the Right Positive Displacement Blower for Wastewater Aeration

Choosing the Right Positive Displacement Blower for Wastewater Aeration

Introduction

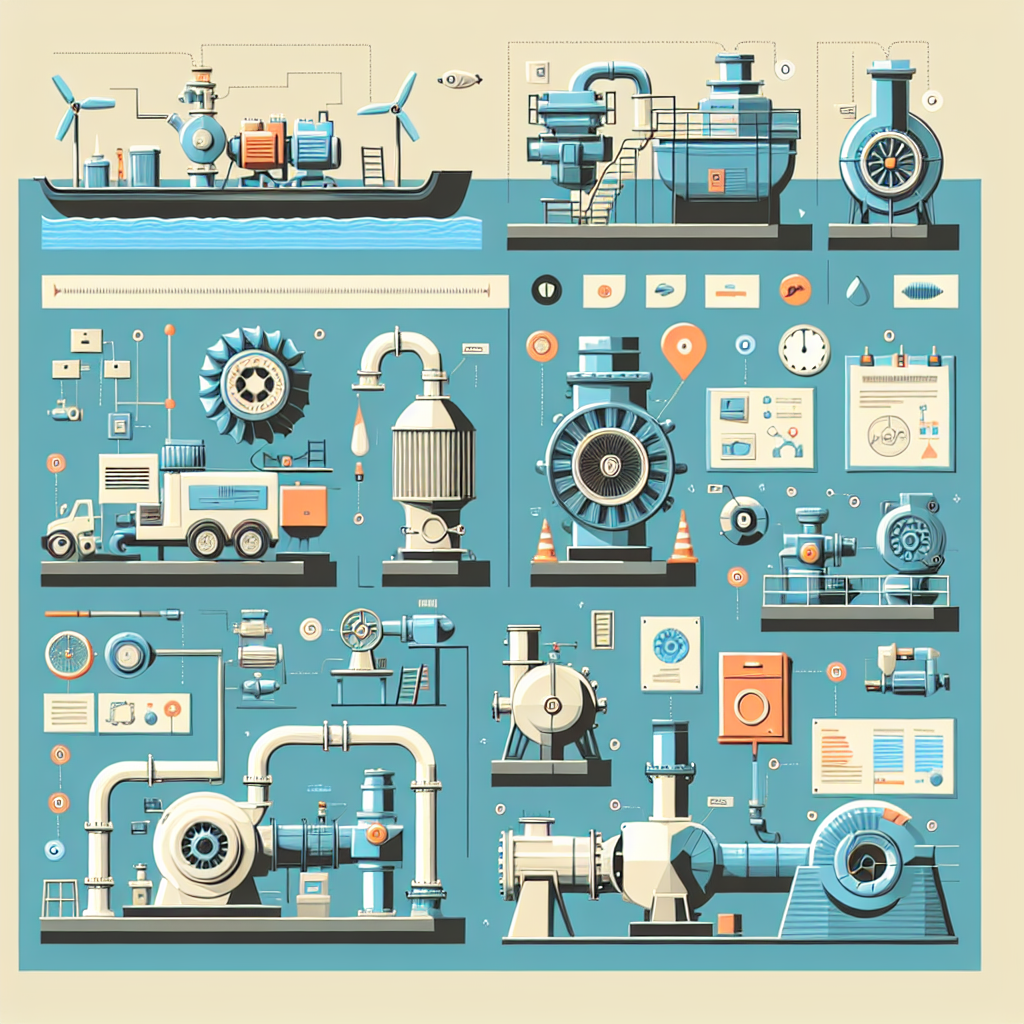

Welcome to the world of positive displacement blowers, where air meets innovation! If you’re knee-deep in the wastewater treatment game, you know that choosing the right blower can feel like trying to find a needle in a haystack except this needle is vital for aeration systems and your plant’s efficiency.

Positive displacement blowers are not just any air blowers; they are the unsung heroes of wastewater treatment. Think of them as the hardworking bees of your aeration system, tirelessly buzzing away to ensure that oxygen is delivered efficiently to those lovely microorganisms doing all the dirty work. Whether you’re dealing with rotary lobe blowers, twin lobe blowers, or even high-pressure variants, each type has its own quirks and benefits.

But hold on! Before you dive into the deep end and pick a blower based on looks alone (yes, we know they can be quite handsome), there’s more to consider. From energy efficiency to maintenance requirements, every detail counts in ensuring your blower systems run smoothly and efficiently.

Did you know? The right positive displacement blower can significantly improve your plant’s overall performance while reducing operational costs. That’s like finding a money tree in your backyard!

In this guide, we’ll explore everything from the various types of positive displacement pumps available to key considerations for selecting the perfect fit for your wastewater treatment needs. So grab your hard hat and let’s get started on this journey towards optimizing your aeration systems with top-notch blower technology!

Understanding Positive Displacement Blowers

Positive displacement blowers are the unsung heroes of air handling equipment, especially when it comes to wastewater aeration. Think of them as the trusty sidekick in a superhero movie: they might not wear a cape, but they sure do save the day by moving air efficiently and reliably.

Did you know? Positive displacement blowers can handle both low and high pressure applications, making them incredibly versatile in various industries!

Definition and Functionality

At their core, positive displacement blowers operate by trapping a fixed volume of air (or gas) and then forcing it into a discharge pipe. This method ensures consistent airflow regardless of system pressure changes, which is crucial for processes like wastewater treatment where maintaining oxygen levels is vital.

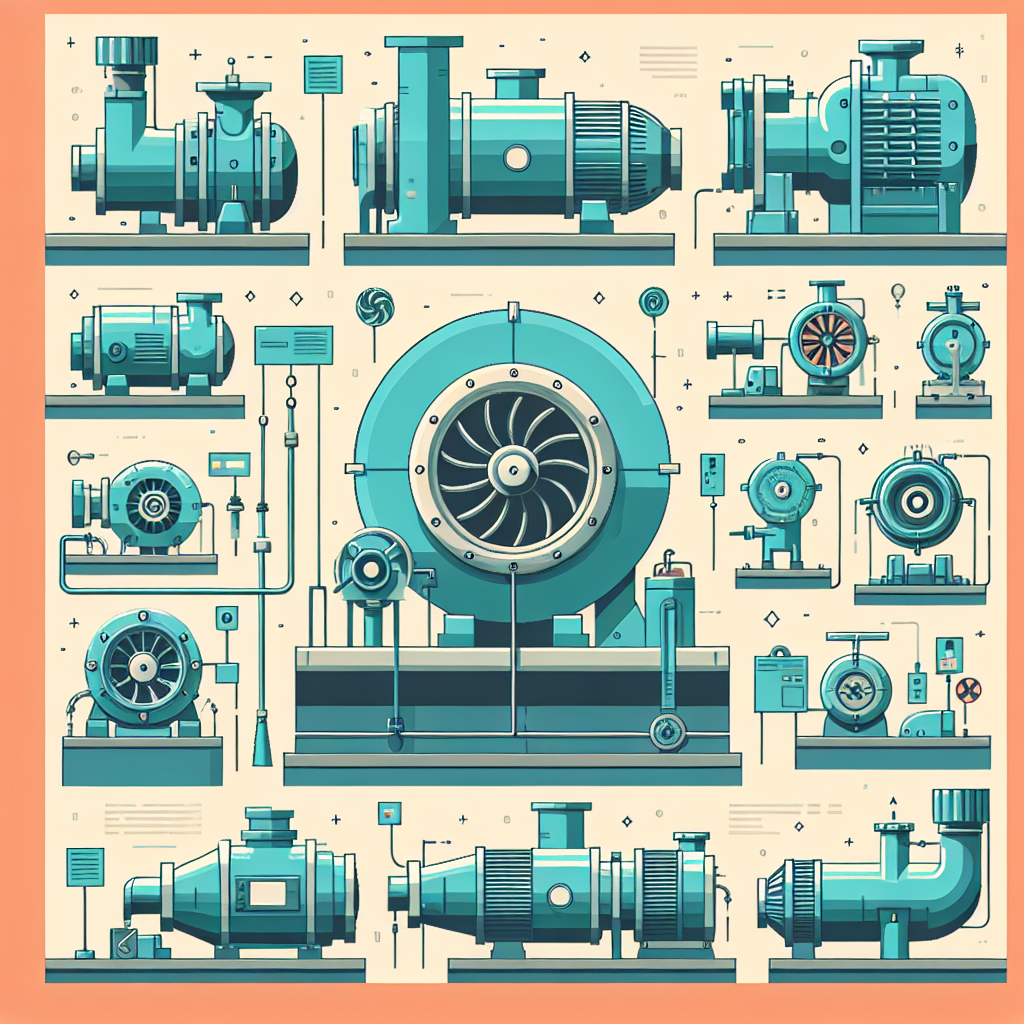

Types of Positive Displacement Blowers

- Twin Lobe Blowers: These work like a well-oiled machine with two lobes rotating in sync to compress air. They are known for their reliability and efficiency in various applications.

- Roots Type Blowers: Named after their inventors, the Roots brothers, these blowers feature two rotors that create a vacuum to draw in air. They excel in high-pressure applications and are commonly found in industrial settings.

- Regenerative Blowers: These nifty devices work by using centrifugal force to move air through a series of impellers. They are particularly effective for low-pressure applications, making them ideal for tasks like aeration in wastewater treatment systems.

No matter the type, all positive displacement blowers share common traits: they deliver high efficiency and consistent performance while requiring minimal maintenance. This makes them an attractive option for municipalities looking to optimize their wastewater treatment processes.

Key Considerations for Choosing a Blower

When it comes to selecting the right positive displacement blowers for your wastewater aeration needs, it’s not just a matter of picking the first one you see. Think of it like dating you need to find the right match that meets your specific requirements. Here are some key considerations to keep in mind:

Application Requirements

Your application dictates the type of blower you’ll need. For instance, if you’re dealing with aeration systems, you might lean towards rotary lobe blowers for their efficiency in moving large volumes of air. On the other hand, if you’re in a biogas application, high pressure blowers may be more appropriate. Consider:

- Type of Wastewater: Different waste types may require different blower technologies.

- System Configuration: Ensure compatibility with existing infrastructure and other air handling equipment.

- Environmental Conditions: Will your blower be exposed to harsh conditions? Choose durable materials accordingly.

Pressure and Flow Rate Needs

The pressure and flow rate requirements are crucial factors that can make or break your blower choice. Too little pressure can lead to inefficiencies, while too much can cause unnecessary wear and tear. Here’s what to consider:

- Determine Required Pressure: Assess whether low pressure or high pressure blowers are necessary based on your aeration system design.

- Flow Rate Calculations: Calculate the required cubic feet per minute (CFM) based on your system’s demands.

- Dynamics of Operation: Understand how variations in flow rate affect overall performance during peak and off-peak times.

Energy Efficiency and Operating Costs

No one wants to spend a fortune on operating costs, especially when energy efficiency is at stake! With energy prices fluctuating like a rollercoaster, it’s essential to consider:

- Blower Efficiency Ratings: Look for models with high efficiency ratings that can save you money in the long run.

- Total Cost of Ownership (TCO): Factor in not just purchase price but also maintenance, energy consumption, and lifespan.

- Sustainability Practices: Choose manufacturers that prioritize eco-friendly practices it’s good for the planet and your budget!

Blower Efficiency and Performance Metrics

When it comes to positive displacement blowers, understanding efficiency and performance metrics is like knowing the secret recipe for your favorite dish. You can’t just throw ingredients together and hope for the best; you need to know what works together to create that perfect blend.

Understanding Blower Efficiency Ratings

Blower efficiency is often expressed as a percentage, indicating how effectively a blower converts input power into useful output. In the world of industrial blowers, this metric can vary widely based on design and application.

- Volumetric Efficiency: This measures the actual flow rate compared to the theoretical flow rate. A higher volumetric efficiency means more air is being moved with less energy.

- Isentropic Efficiency: This rating shows how well the blower performs under ideal conditions. It’s a bit like comparing your cooking skills with Gordon Ramsay’s you want to get as close as possible!

- Overall Efficiency: This considers both mechanical losses and heat losses, giving you a complete picture of how well your blower system operates.

Impact of Design on Performance

The design of positive displacement blowers plays a crucial role in their performance metrics. Here are some key design elements that affect efficiency:

- Lobe Design: For rotary lobe blowers, the shape and spacing of lobes significantly influence airflow and pressure capabilities. Twin lobe blowers might be great for low-pressure applications, while roots type blowers excel in high-pressure scenarios.

- Material Selection: Using high-quality materials can reduce friction and wear, leading to better performance over time. Think of it as choosing between a fancy chef’s knife versus an old rusty one!

- Piping Configuration: The layout of your piping can create resistance in airflow. An optimal configuration minimizes bends and turns, enhancing overall efficiency.

Pro Tip: Regularly monitoring blower performance metrics not only helps in identifying potential issues early but also ensures that you’re operating at peak efficiency saving energy costs!

A common misconception is that all blowers are created equal; however, choosing the right type for your application can drastically affect both performance and energy consumption. Whether it’s for wastewater treatment or pneumatic conveying systems, understanding these metrics will help you make informed decisions.

The takeaway? When selecting your next positive displacement blower, don’t just look at price tags dive into those efficiency ratings! Because at the end of the day, every percentage point counts when it comes to operational costs.

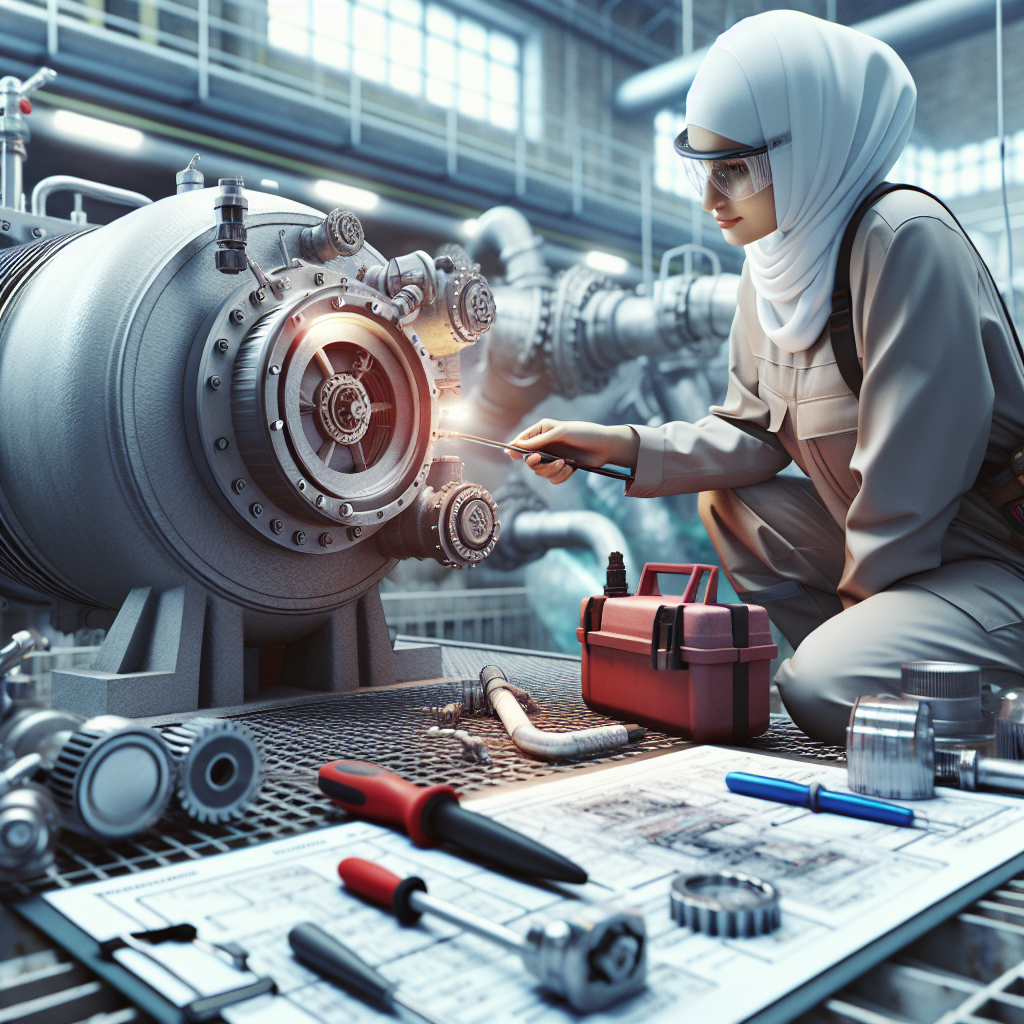

Blower Maintenance and Reliability

When it comes to positive displacement blowers, maintenance is not just a good idea it’s essential. Think of it like your car: regular oil changes and tune-ups keep it running smoothly and efficiently. Similarly, proper maintenance of your blower systems ensures reliability and longevity, preventing costly downtime in wastewater treatment operations.

Regular Maintenance Practices

To keep your positive displacement blowers in tip-top shape, follow these regular maintenance practices:

- Routine Inspections: Check for vibrations, unusual noises, or leaks. If it sounds like a rock band in there, you might need to investigate!

- Air Filter Replacement: Dirty filters can choke the airflow and reduce efficiency. Change them out regularly to maintain optimal performance.

- Lubrication: Ensure that all moving parts are well-lubricated. This will minimize wear and tear on components like rotary lobe blowers.

- Belt Checks: If you’re using belt-driven blowers, inspect the belts for wear and proper tension. A loose belt can lead to slippage like trying to run in flip-flops!

- Monitor Operating Conditions: Keep an eye on temperature and pressure readings. If something seems off, don’t ignore it addressing issues early can save you from bigger headaches later.

Troubleshooting Common Issues

No one likes a surprise breakdown! Here are some common issues with positive displacement pumps and how to troubleshoot them:

- Poor Performance: If your blower isn’t delivering the expected flow rate or pressure, check for blockages in the intake or exhaust lines.

- Excessive Noise: Unusual sounds could indicate misalignment or worn bearings time to break out the toolbox!

- Vibration Problems: Excessive vibration can often be traced back to imbalanced rotors or loose mounting bolts. Tighten those bolts before they become a nuisance.

- Oil Leaks: If you notice oil pooling around your unit, inspect seals and gaskets for wear. A small leak can lead to big problems if left unattended.

The bottom line? By staying proactive with maintenance and troubleshooting common issues promptly, you’ll keep your industrial blowers running smoothly through every aeration cycle. So roll up those sleeves you’ve got this!

Selecting the Right Manufacturer and Supplier

When it comes to positive displacement blowers, choosing the right manufacturer and supplier can be as crucial as selecting the right model. Think of it like picking a partner for a dance you want someone who knows the steps, understands your rhythm, and can keep up with your moves!

Criterions for Choosing a Supplier

Here are some key factors to consider when sifting through potential suppliers:

- Experience: Look for suppliers who specialize in industrial blowers and have a proven track record in the wastewater treatment sector.

- Product Range: Ensure they offer a variety of positive displacement blowers, including rotary lobe blowers, roots type blowers, and regenerative blowers to suit your specific needs.

- Customer Support: Opt for suppliers known for excellent customer service. Quick responses can save you from potential headaches down the line.

- Warranty and Maintenance Services: Check if they provide maintenance services or warranties that cover parts and labor. A good warranty is like having an insurance policy on your air blower investment!

- Reviews and References: Don’t hesitate to ask for references or read reviews from other municipalities or engineers who have worked with them.

Evaluating Manufacturer Reputation and Support Services

A strong manufacturer reputation is often built on reliability, innovation, and support. Here’s how to evaluate this:

- Industry Recognition: Look for manufacturers that have received awards or certifications in blower technology or environmental control equipment.

- Technical Support: Assess their technical support availability. Are they just a phone call away when you need assistance with blower installation or troubleshooting?

- Research and Development: Consider manufacturers that invest in R&D. This indicates they are committed to improving blower efficiency and performance metrics.

- Sustainability Practices: In today’s eco-conscious world, partnering with manufacturers who prioritize energy-efficient blower solutions can align well with your sustainability goals.

The right manufacturer not only provides quality products but also becomes a partner in your operational success. Make sure their values align with yours!

Selecting the right partner in this journey is essential; after all, you want your positive displacement blowers humming along smoothly while you focus on what really matters effective wastewater treatment!

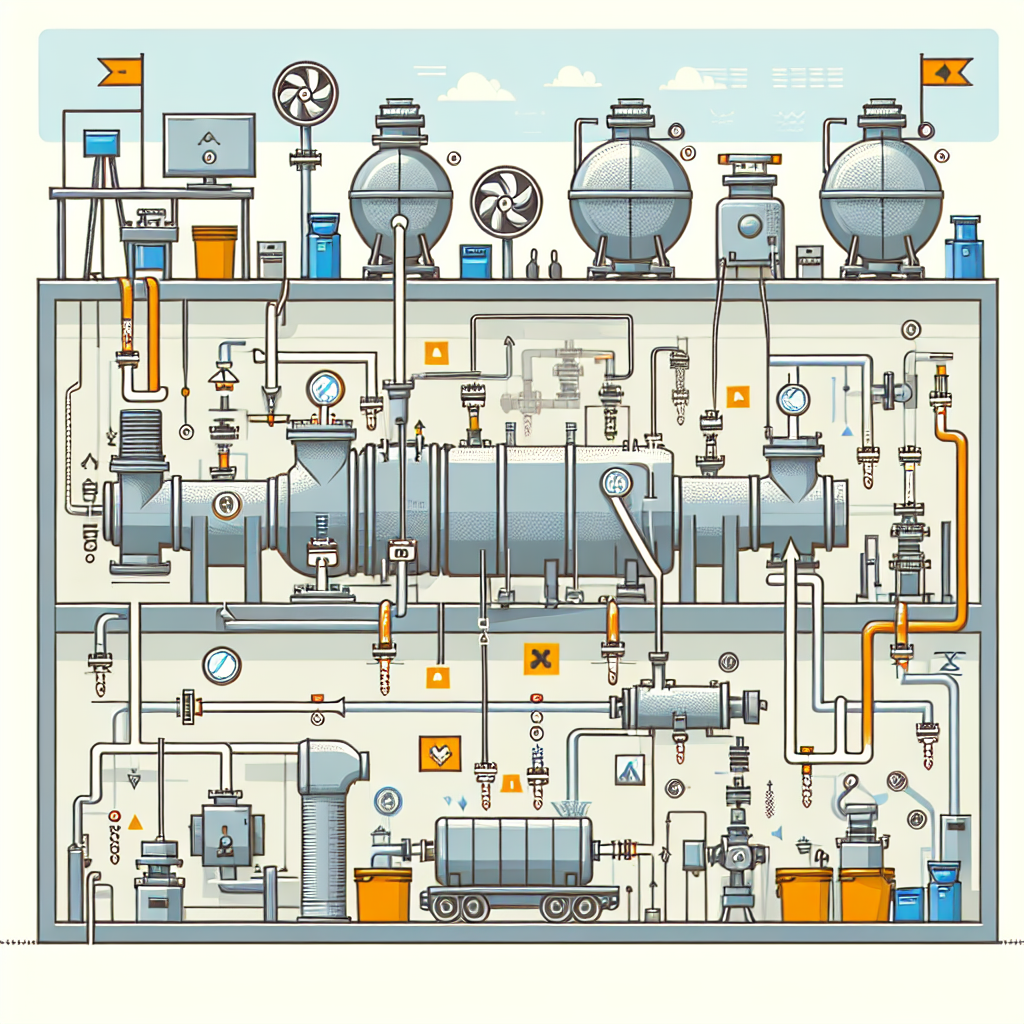

Installation Considerations for Optimal Performance

Installing positive displacement blowers, particularly in wastewater aeration systems, is like setting the stage for a grand performance. If done right, the show will go on smoothly; if not, you might find yourself in a comedy of errors. Here are some key considerations to ensure your blower systems hit all the right notes.

1. Location, Location, Location

The placement of your positive displacement blowers is crucial. Ideally, they should be installed as close as possible to the application area to minimize pressure drops and maximize efficiency. Think of it as putting your favorite band on stage versus in the back room you want them front and center!

2. Vibration Isolation

Blower technology can get a bit noisy and vibrate like an over-caffeinated drummer. To mitigate these effects, use vibration isolation mounts or pads. This not only protects the blower but also reduces noise pollution in your facility.

3. Air Handling Equipment Compatibility

Your positive displacement blowers need to play well with other air handling equipment in your system. Ensure compatibility with piping systems, valves, and even filters. A mismatch here can lead to inefficiencies that would make even the best performers sound off-key.

4. Adequate Ventilation

Blowers can generate heat during operation think of them as running marathons while wearing winter coats! Make sure there’s adequate ventilation around your blowers to keep them cool and operating efficiently.

5. Accessibility for Maintenance

Your installation should allow for comfortable access without needing an engineering degree or a gym membership just to reach those hard-to-get spots.

6. Electrical Supply Considerations

Ensure that your electrical supply meets the requirements of high pressure blowers or low pressure blowers as applicable. Consult with a qualified electrician if necessary; you don’t want any surprises when it’s showtime!

7. Compliance with Local Regulations

Last but definitely not least, check local regulations regarding emissions and noise levels from industrial blowers. Failing to comply could lead to fines that’ll make you wish you had just paid more attention during installation!

In summary: Proper installation of positive displacement blowers is essential for optimal performance in wastewater aeration systems. By considering location, vibration isolation, compatibility with air handling equipment, adequate ventilation, accessibility for maintenance, electrical needs, and regulatory compliance, you’ll be setting yourself up for success.

If you’re ready to dive deeper into specific blower applications or need guidance on choosing the right model from reputable blower manufacturers or suppliers, stay tuned!

Applications of Positive Displacement Blowers in Wastewater Treatment

When it comes to wastewater treatment, positive displacement blowers are the unsung heroes of aeration systems. These industrious little machines ensure that the microbial party in your treatment plant stays lively by providing the necessary oxygen for bacteria to break down waste. Let’s dive into the various roles these blowers play in keeping our water clean and our ecosystems thriving.

1. Aeration Systems

Aeration is crucial in wastewater treatment, and positive displacement blowers are at the forefront of this process. By delivering a steady supply of air, these blowers help maintain optimal dissolved oxygen levels in aeration tanks. This is where our friendly neighborhood bacteria do their dirty work literally!

2. Sludge Treatment Systems

Sludge management can be a sticky business (pun intended). Positive displacement blowers assist in the aeration of sludge, promoting aerobic digestion and reducing odors. Think of them as the air traffic controllers for all that gooey goodness, ensuring everything runs smoothly.

3. Biogas Applications

In anaerobic digestion processes, where organic matter breaks down without oxygen, positive displacement blowers can be used to manage biogas collection and transport. These high-pressure blowers help move biogas safely through pneumatic conveying systems, making sure that nothing goes to waste literally!

4. Chemical Processing

In chemical processing applications within wastewater treatment plants, positive displacement pumps paired with blowers facilitate the mixing and transfer of chemicals used for disinfection or pH adjustment. They ensure that every drop counts when it comes to maintaining water quality.

5. Energy Efficiency Considerations

Blower efficiency is a hot topic in wastewater treatment facilities looking to reduce energy costs. Modern positive displacement blowers are designed with advanced blower technology that optimizes performance while minimizing energy consumption. This means you can save money while keeping your operations eco-friendly!

Mistakes to Avoid

- Poor Sizing: Choosing a blower that’s too small or too large can lead to inefficiencies or even system failures.

- Nagging Maintenance: Neglecting regular maintenance can cause unexpected breakdowns nobody wants a surprise visit from the repairman during peak hours!

- Inefficient Installation: Improper installation can hinder performance; make sure your blower systems are set up correctly from day one.

The applications of positive displacement blowers in wastewater treatment are as diverse as they are critical. By understanding how these devices function within various processes from aeration to biogas management you’ll be better equipped to choose the right blower system for your needs.

Conclusion

Choosing the right positive displacement blowers for wastewater aeration is no small feat. With a plethora of options ranging from rotary lobe blowers to high-pressure and low-pressure variants, it can feel like you’re navigating a maze of blower technology. But fear not, dear reader! By understanding your specific needs and application requirements, you can confidently select the ideal blower system that will keep your wastewater treatment processes running smoothly.

Remember, efficiency is key. Not only do you want a blower that meets your flow rate and pressure needs, but you also want one that excels in blower efficiency. Regular maintenance practices will ensure longevity and reliability, allowing you to avoid common pitfalls that can lead to costly downtimes. And let’s be honest, nobody wants to deal with unexpected repairs when there’s sludge to manage!

As municipalities and engineers continue to prioritize sustainable practices in wastewater treatment, embracing advanced blower technology becomes crucial. Whether you’re dealing with biogas applications or pneumatic conveying systems, the right choice in blowers can significantly impact operational success.

So go ahead! Dive into those specifications, evaluate potential suppliers carefully, and make an informed decision that will benefit both your operations and the environment. Your wastewater treatment plant and the planet will thank you!

article blockquote,article ol li,article p,article ul li{font-family:inherit;font-size:18px}.featuredimage{height:300px;overflow:hidden;position:relative;margin-top:20px;margin-bottom:20px}.featuredimage img{width:100%;height:100%;top:50%;left:50%;object-fit:cover;position:absolute;transform:translate(-50%,-50%)}article p{line-height:30px}article ol li,article ul li{line-height:30px;margin-bottom:15px}article blockquote{border-left:4px solid #ccc;font-style:italic;background-color:#f8f9fa;padding:20px;border-radius:5px;margin:15px 10px}article div.info-box{background-color:#fff9db;padding:20px;border-radius:5px;margin:15px 0;border:1px solid #efe496}article table{margin:15px 0;padding:10px;border:1px solid #ccc}article div.info-box p{margin-bottom:0;margin-top:0}article span.highlight{background-color:#f8f9fb;padding:2px 5px;border-radius:5px}article div.info-box span.highlight{background:0 0!important;padding:0;border-radius:0}article img{max-width:100%;margin:20px 0}