4D-Printed Smart Materials For Water Treatment

4D-Printed Smart Materials for Water Treatment: A Revolutionary Approach to Clean Water

Introduction

In the face of escalating water shortages and contamination issues globally, innovative technologies are urgently needed to ensure a sustainable supply of clean water. Among the emerging solutions, 4D printing of smart materials stands out as a groundbreaking advance in the field of water treatment. This article explores the concept, design principles, and applications of 4D-printed smart materials in water purification, providing an in-depth understanding of how this technology promises to revolutionize water treatment processes.

Understanding 4D Printing and Smart Materials

What is 4D Printing?

4D printing extends the concept of 3D printing by incorporating the dimension of time, hence the ‘fourth dimension.’ While 3D printing builds objects layer by layer using materials based on a digital model, 4D printing uses stimuli-responsive materials that can change their shape, properties, or functionalities over time when exposed to certain environmental triggers such as temperature, pH, humidity, or light.

Smart Materials in Water Treatment

Smart materials, also known as responsive materials, are capable of altering their properties in response to external stimuli. In water treatment, these materials can be engineered to respond to contaminants or environmental conditions, leading to improved efficiency and adaptability of the treatment process. When integrated with 4D printing, these smart materials can be fabricated into complex and dynamic structures, enhancing their performance and application scope in water treatment.

Mechanisms of 4D-Printed Smart Materials

Stimuli-Responsive Behavior

The core mechanism in 4D-printed smart materials lies in their ability to react to specific stimuli. Common stimuli include:

-

- Temperature: Shape-memory polymers (SMPs) and hydrogels can expand, contract, or change their conformation in response to temperature changes, allowing them to capture and release contaminants.

-

- pH Level: Materials can be engineered to react to pH changes in the water, enabling them to adsorb contaminants selectively or to signal when the water reaches a certain purity level.

-

- Light: Photoreactive materials change their properties under certain wavelengths of light, which can be used to trigger contaminant degradation or purification processes.

-

- Magnetic Fields: Magnetoresponsive materials can be manipulated using external magnetic fields, aiding in the separation and removal of contaminants.

Design and Fabrication Techniques

The design of 4D-printed smart materials for water treatment involves several critical steps:

-

- Material Selection: Identifying suitable polymers, hydrogels, and composites that respond predictably to the desired stimuli.

-

- Modeling and Simulation: Creating digital models to simulate the material’s behavior under different conditions, ensuring that the final product will perform as required.

-

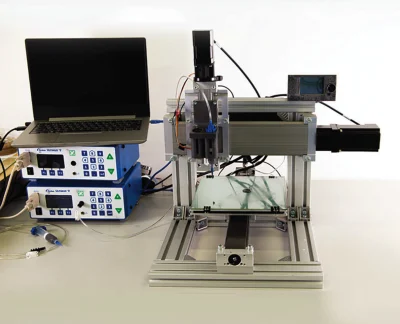

- Additive Manufacturing: Utilizing advanced 3D printing techniques like stereolithography (SLA), selective laser sintering (SLS), and fused deposition modeling (FDM) to fabricate the materials.

-

- Post-Processing: Applying treatments such as curing, conditioning, and coating to enhance the material’s responsiveness and durability.

Applications of 4D-Printed Smart Materials in Water Treatment

The integration of 4D-printed smart materials in water treatment has the potential to vastly improve various processes, making them more efficient, responsive, and cost-effective. Key applications include:

Adsorption of Contaminants

One of the primary applications of 4D-printed smart materials is the adsorption of pollutants. Traditional materials used in water treatment often face challenges such as limited adsorption capacity and difficulty in regenerating the adsorbent material. 4D-printed materials, however, can be designed to:

-

- Maximize Surface Area: Complex geometries can be printed to increase the surface area available for adsorption, enhancing the material’s capacity to capture contaminants.

-

- Regeneration Capability: Materials can be engineered to switch between adsorption and desorption states in response to specific stimuli, making it easier to clean and regenerate the adsorbent.

-

- Selective Adsorption: Functional groups can be incorporated into the material to target specific contaminants, thereby improving the efficiency and selectivity of the treatment process.

Filtration Systems

In filtration, 4D-printed smart materials can be pivotal in designing self-cleaning and adaptive filters. Traditional filters often suffer from clogging and degradation over time. However, 4D-printed filters can:

-

- Alter Pore Size: Responsively change their pore size to prevent clogging and maintain consistent flow rates.

-

- Self-Healing: Repair minor damages autonomously, extending the filter’s lifespan and reducing maintenance costs.

-

- Dynamic Filtration: Adjust their filtration properties in real-time based on water quality, optimizing performance under varying conditions.

Catalytic Degradation of Pollutants

Catalysis is another critical area where 4D-printed smart materials can significantly contribute. These materials can host catalysts that degrade organic pollutants through chemical reactions. Key benefits include:

-

- Increased Reaction Rates: The dynamic nature of the materials can improve contact between the catalyst and pollutants, accelerating reaction rates.

-

- Targeted Activation: Catalytic sites can be activated selectively in response to specific stimuli, enhancing the efficiency of pollutant degradation.

-

- Robust Structure: 4D-printed materials provide a sturdy platform for immobilizing catalysts, preventing catalyst leaching and maintaining long-term activity.

Desalination Processes

Desalination is crucial for converting seawater and brackish water into potable water. 4D-printed smart materials can enhance both thermal and membrane-based desalination methods:

-

- Dynamic Membranes: Membranes that adjust their porosity and hydrophilicity based on water salinity or temperature, optimizing salt rejection and water permeability.

-

- Energy Efficiency: Materials that reduce energy consumption by dynamically managing heat and mass transfer processes.

-

- Anti-Fouling Properties: Surface modifications that prevent fouling, a common issue in conventional desalination membranes, thereby improving performance and reducing maintenance costs.

Sensing and Monitoring

Monitoring water quality in real-time is essential for effective water management. 4D-printed smart materials can be integrated into sensors to provide accurate and timely data on various water quality parameters such as pH, temperature, contaminant levels, and turbidity. These sensors can:

-

- React to Changes: Instantly respond to changes in water quality, providing real-time data and alerts.

-

- Multi-Functional Sensing: Combine multiple functionalities into a single sensor, reducing the number of devices needed and simplifying the monitoring system.

-

- Long-Term Stability: Maintain their sensitivity and accuracy over extended periods, ensuring reliable performance.

Case Studies and Research Highlights

Case Study 1: 4D-Printed Hydrogels for Heavy Metal Removal

Researchers have developed 4D-printed hydrogels capable of removing heavy metals from contaminated water. These hydrogels exhibit significant changes in volume in response to temperature variations. By cycling the temperature, the hydrogels can capture and release heavy metals, making the regeneration process efficient and cost-effective. Experimental results showed a high adsorption capacity for metals like lead and cadmium, demonstrating the hydrogel’s potential for industrial and environmental applications.

Case Study 2: Shape-Memory Polymers in Filtration Systems

A study focused on the use of shape-memory polymers (SMPs) to create adaptive filtration systems. SMPs were printed into filters with adjustable pore sizes that respond to water flow rates. Under high flow conditions, the pores expanded to prevent clogging, while they contracted under low flow conditions to enhance filtration efficiency. The adaptive filters demonstrated prolonged operational life and maintained their filtration capabilities significantly better than traditional filters.

Case Study 3: Photoreactive Materials for Catalyst Activation

4D-printed photoreactive materials embedded with catalytic particles were designed for the degradation of organic dyes in wastewater. These materials changed their surface properties under UV light, exposing catalytic sites and initiating the degradation process. The study showed a substantial increase in the rate of dye degradation compared to non-responding materials, highlighting the effectiveness of using light-triggered materials in catalytic applications.

Challenges and Future Directions

Technical Challenges

Despite the promising potential, several technical challenges need to be addressed to fully realize the benefits of 4D-printed smart materials in water treatment:

-

- Material Stability: Ensuring long-term stability and performance of the materials under varying environmental conditions.

-

- Cost and Scalability: Reducing the cost of raw materials and the printing process to make the technology economically viable for large-scale applications.

-

- Complex Design and Modeling: Developing more sophisticated design tools and simulation models to accurately predict and optimize material behavior.

Environmental and Regulatory Considerations

The deployment of 4D-printed smart materials in water treatment must also consider environmental and regulatory factors:

-

- Environmental Impact: Assessing the environmental impact of the materials throughout their lifecycle, including production, usage, and disposal.

-

- Regulatory Approval: Ensuring that the materials and technologies meet regulatory standards for safety and efficacy in different regions and applications.

Future Research Directions

Future research should focus on the following areas to advance the field:

-

- Material Innovation: Developing new stimuli-responsive materials with enhanced properties and broader responsiveness to different stimuli.

-

- Integration with Existing Systems: Creating hybrid systems that combine 4D-printed materials with traditional water treatment technologies for improved performance.

-

- Real-World Testing: Conducting pilot studies and real-world testing to validate the effectiveness and practicality of the materials in diverse water treatment scenarios.

Conclusion

The advent of 4D-printed smart materials heralds a new era in water treatment technology. By leveraging the dynamic and responsive nature of these materials, we can develop more efficient, adaptable, and sustainable solutions for managing water resources. As research and development continue to advance, the integration of 4D-printed materials in water treatment systems holds the potential to address some of the most pressing water-related challenges of our time, ensuring a cleaner and safer water supply for future generations.