Complete Water Filtration Methods for Municipal Treatment Systems

Complete Water Filtration Methods for Municipal Treatment Systems

Complete Water Filtration Methods for Municipal Treatment Systems

Introduction

Over 2 billion people worldwide lack access to safely managed drinking water services, and that’s just a staggering reality check. The filtration of water is not merely a technical requirement; it’s a lifeline. For municipalities, ensuring that clean drinking water flows from taps isn’t just a service it’s a responsibility.

Municipal treatment systems are the unsung heroes in this saga, transforming murky supplies into crystal-clear H2O. Think of them as the ultimate bouncers at the club of hydration, filtering out unwanted guests like bacteria, heavy metals, and even pesky chlorine. But how do they do it? What methods are at their disposal?

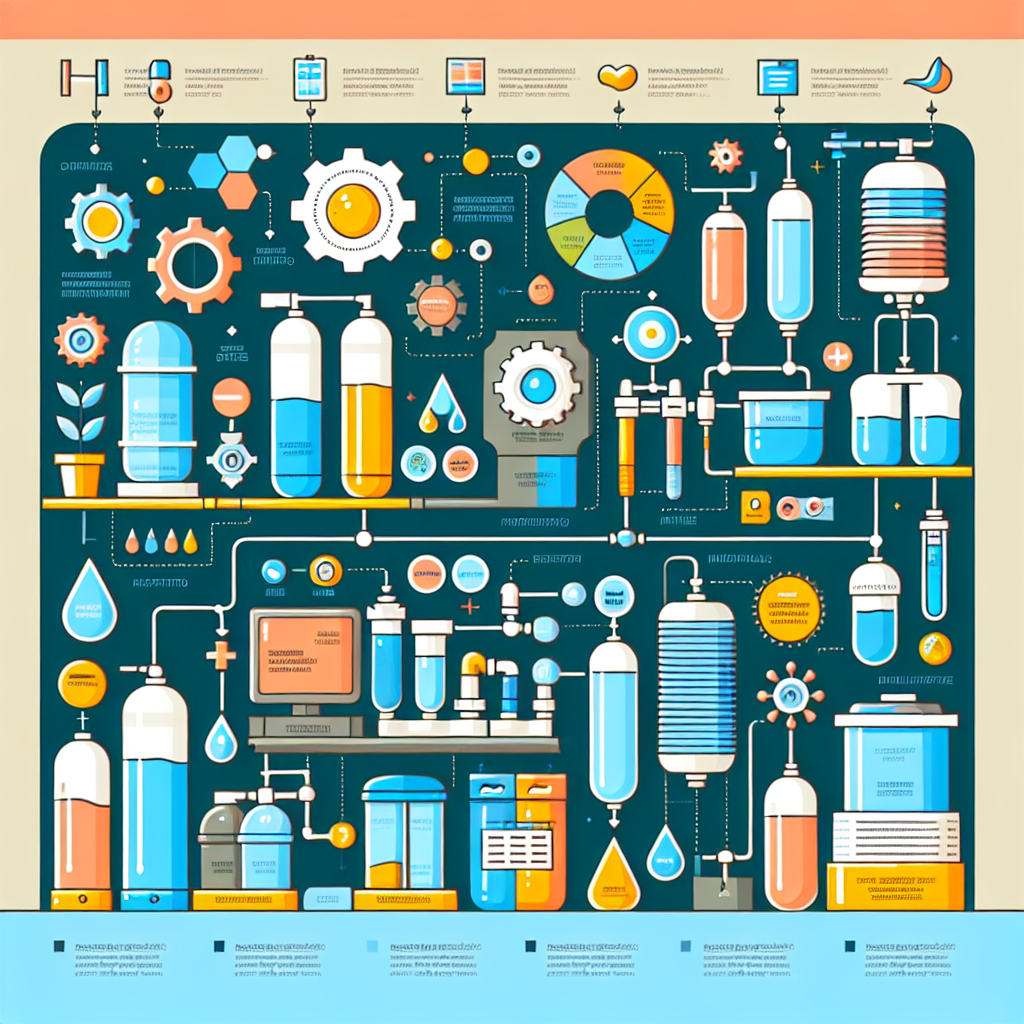

This post will unpack the various methods employed in municipal water treatment systems everything from simple sediment filters to complex reverse osmosis setups. We’ll also explore the latest innovations that make these systems more efficient and eco-friendly.

Ready to dive into the world of water filtration? Grab your favorite beverage (preferably one that’s been filtered) and let’s get started!

Overview of Filtration of Water in Municipal Systems

Let’s face it: nobody wants to drink water that looks like it came from a muddy puddle. The filtration of water in municipal systems isn’t just a luxury; it’s a necessity for public health and safety. Clean drinking water is the backbone of any community, and without effective filtration methods, we’d be in deep trouble.

The role of filtration in water treatment cannot be overstated. It’s the superhero cape that transforms potentially harmful H2O into the refreshing liquid we all need to survive. Various techniques are employed, from sediment filtration to advanced reverse osmosis systems, each playing a vital part in ensuring our taps flow with clean water.

- Importance of water purification: Water sources can be contaminated with bacteria, viruses, heavy metals, and other pollutants. Effective filtration removes these harmful substances, safeguarding public health.

- Role of filtration in water treatment: Filtration acts as the first line of defense against contaminants. It’s not just about filtering out dirt; it’s about providing clean drinking water that meets safety standards.

- Challenges faced by municipalities: From aging infrastructure to budget constraints, municipalities often struggle to maintain effective filtration systems. This leads to potential risks for communities relying on their local water supply.

Here’s the kicker: many municipalities still rely on outdated filtration technologies that can’t keep up with modern contamination challenges. It’s time for a wake-up call! Upgrading to smarter solutions like UV water purification or advanced carbon block filters can drastically improve water quality.

In addition to technology hurdles, there are also environmental considerations. With climate change affecting rainfall patterns and increasing pollution levels, municipalities must adapt their filtration strategies accordingly. This means investing not only in new technology but also in sustainable practices that ensure future generations have access to clean drinking water.

The interesting part? Municipalities are beginning to embrace eco-friendly solutions that not only purify but also protect our planet. Think about it: what if your local system could filter out contaminants while reducing its carbon footprint? The future is looking bright for innovative municipal treatments!

As we move forward into an era where clean drinking water should be a given rather than a privilege, understanding the intricacies of the filtration process becomes essential for engineers and operators alike. The goal is clear: enhance existing systems while exploring new technologies to meet growing demands.

Types of Water Filtration Methods

Water filtration isn’t just a trendy buzzword; it’s a necessity for clean drinking water. With the myriad of filtration methods available, each has its own role in the grand scheme of municipal water treatment. Let’s break down the most common types that make our water safe and palatable.

Sediment filtration is often the first line of defense against dirt, rust, and other particles. Think of it as your water’s bouncer, keeping the unwanted guests out!

- Sediment Filtration: This method employs filters that trap larger particles like sand and silt. It’s crucial for protecting downstream equipment from wear and tear.

- Activated Carbon Filters: These bad boys are like sponges for bad tastes and odors. They work by adsorbing contaminants such as chlorine, volatile organic compounds (VOCs), and even some heavy metals. If your water tastes funky, activated carbon is likely your best friend.

- Reverse Osmosis Systems: RO systems are akin to a superhero for your water, using pressure to push it through a semi-permeable membrane. This process removes up to 99% of dissolved solids, bacteria, and viruses making it one of the most effective methods for ensuring purity.

- UV Water Purification: Ultraviolet light isn’t just for tanning; it’s also a powerful germ killer! UV systems neutralize bacteria and viruses without adding chemicals to your water perfect for those who want to keep things natural yet effective.

- Ionic Exchange Filtration: This method is particularly popular in softening hard water by swapping out calcium and magnesium ions with sodium or potassium ions. If you’ve ever experienced limescale build-up in your appliances, this one’s a game-changer!

- Alkaline Water Filters: These filters not only purify but also raise the pH level of drinking water. Advocates claim alkaline water can help neutralize acidity in the body though scientific backing varies widely.

The interesting part? Not all filtration methods are created equal! Each has its strengths tailored to specific contaminants or issues faced by municipal systems. For instance, while sediment filters excel at removing large particles, they won’t touch dissolved chemicals or pathogens that’s where activated carbon or reverse osmosis comes into play.

When selecting a filtration system, consider what you’re filtering out. A combination of these methods often yields the best results for comprehensive treatment after all, why settle for just one filter when you can have a whole team working together?

Advanced Filtration Techniques for Enhanced Purity

When it comes to the filtration of water, not all heroes wear capes. Some come in the form of advanced filtration techniques that elevate the purity of our drinking water to superhero status. Municipalities are increasingly turning to these sophisticated methods not just for compliance but for the health and safety of their communities.

Carbon block filters can reduce contaminants like chlorine, lead, and sediment by up to 99%, making them a game-changer in municipal treatment systems.

Carbon Block Filters

If you think all carbon filters are created equal, think again! Carbon block filters are like the Swiss Army knives of water filtration. They combine activated carbon’s adsorption capabilities with a dense structure that captures even the tiniest particles. This dual action means they’re fantastic at reducing harmful chemicals while improving taste and odor. In fact, many municipalities have adopted these filters in their systems to tackle issues like chlorine reduction and heavy metal removal.

Ceramic Water Filters

Ceramic filters might sound old-school, but they’re still one of the most effective ways to ensure clean drinking water. These filters work through a process called microfiltration, effectively blocking bacteria and protozoa while allowing clean water to pass through. Imagine a tiny sieve that catches the bad guys these filters can remove pathogens down to 0.2 microns! Plus, they’re eco-friendly and reusable, making them an attractive option for both municipal systems and home users alike.

Bacteria and Virus Removal Filters

With increasing concerns about waterborne diseases, bacteria and virus removal filters have become essential in municipal treatment systems. These advanced technologies often employ UV light or chemical disinfectants to neutralize harmful microorganisms without adding any unwanted chemicals to the water supply. The interesting part? Some systems even integrate this technology with existing filtration methods like reverse osmosis or activated carbon for a multi-barrier approach that ensures maximum safety.

But here’s where things break down: not all municipalities utilize these advanced techniques effectively. A common misconception is that basic sediment filtration is sufficient for safe drinking water; however, this is far from reality. If you’re relying solely on sediment filters in your municipal system, you might be leaving your community vulnerable to contaminants lurking beneath the surface.

In conclusion, investing in advanced filtration techniques is no longer optional it’s essential for ensuring public health and delivering clean drinking water. Municipalities must embrace these technologies if they want to keep up with modern standards of water treatment. Next time you fill your glass from the tap, consider what innovative methods might be working behind the scenes!

Filtration Systems for Different Applications

Not all filtration systems are created equal. Depending on the application, you need a tailored approach to ensure the filtration of water is effective. Let’s break down the primary systems used in municipal treatment facilities and point-of-use solutions.

Municipal water treatment facilities often utilize large-scale filtration systems designed to handle massive volumes of water, while point-of-use filtration solutions cater to individual households or specific applications.

Municipal Water Treatment Facilities

At the heart of municipal water treatment, you’ll find complex filtration systems that serve entire communities. These facilities typically employ a combination of methods:

- Sediment Filtration: This is the first line of defense, removing larger particles like dirt and debris before they can cause havoc downstream.

- Activated Carbon Filters: These beauties absorb chlorine, volatile organic compounds (VOCs), and even some heavy metals, ensuring that what flows from your tap isn’t just clean but also tasty.

- Reverse Osmosis Systems: Often used for advanced purification, these systems can remove up to 99% of contaminants, including lead and fluoride. They’re like the bouncers at an exclusive club only the good stuff gets through!

- UV Water Purification: This method zaps bacteria and viruses with ultraviolet light. It’s efficient and eco-friendly no chemicals required!

Point of Use Filtration Solutions

If you think municipal systems have all the fun, think again! Point-of-use (POU) filters are gaining traction in homes across the globe. They’re compact, convenient, and pack a punch when it comes to purifying your drinking water:

- Ceramic Water Filters: Perfect for individual households or camping trips! They filter out bacteria and sediment while being eco-friendly.

- Faucet-Mounted Filters: These are easy to install and provide immediate access to filtered water right from your kitchen sink. Talk about convenience!

- Pitcher Water Filters: A classic choice for many households; they’re simple yet effective for removing chlorine taste and odor.

- Inline Water Filters: Installed directly into your plumbing system, these filters provide continuous clean drinking water without taking up counter space.

The Versatility Factor

The versatility of these filtration systems is key. Whether you’re dealing with well water treatment or looking for an emergency water filtration solution during a natural disaster, there’s a system designed for that specific application.

The takeaway? Understanding your specific needs whether it’s for clean drinking water at home or treating large quantities at a municipal facility will guide you in selecting the right filtration system. Don’t just settle; ensure you’re equipped with the best tools for optimal water purification!

Eco-Friendly and Smart Home Filtration Options

Imagine a filtration system that not only cleans your water but also saves the planet sounds like a dream, right? Well, welcome to the age of eco-friendly and smart home filtration systems. With growing concerns about environmental impact and health, these options are making waves in the water purification scene.

First off, let’s talk about BPA-free filters. These are essential for anyone serious about clean drinking water. BPA (Bisphenol A) is a nasty little chemical found in many plastics that can leach into your water. Opting for BPA-free filters means you’re not just filtering your water but also eliminating harmful chemicals from your life.

Did you know? Over 90% of plastic waste is never recycled, making eco-friendly filtration options crucial for sustainability.

Smart Technology Meets Water Filtration

The interesting part? Smart home filtration systems are here to revolutionize how we think about water purification. Imagine being able to monitor your water quality right from your smartphone! Systems like those equipped with IoT technology can alert you when filters need changing or if there’s a drop in water quality. It’s like having a personal assistant for your hydration needs!

Types of Eco-Friendly Filters

- Gravity-Fed Water Filters: These require no electricity and can filter out bacteria and sediment effectively.

- Ceramic Water Filters: Made from natural materials, these filters are excellent at removing contaminants while being environmentally friendly.

- Activated Carbon Filters: Not only do they improve taste by removing chlorine and odors, but they are also highly effective against heavy metals.

- Portable Water Filters: Perfect for camping or emergency situations, these filters allow you to purify well or municipal water on-the-go.

The Role of Whole House Filtration Systems

If you’re serious about clean drinking water throughout your home, consider whole house filtration systems. They treat all incoming water think showers, dishwashers, and even your garden hose! This means no more worrying about contaminants lurking in unexpected places. Plus, many of them come with eco-friendly options that minimize waste while maximizing efficiency.

A Few Misconceptions

A common myth is that all filtration systems require extensive maintenance or are too costly to install. In reality, many modern systems offer low-maintenance solutions with long-lasting filters that won’t break the bank. Brands like AquaSana and Berkey have made it easier than ever to have high-quality filtration without constant upkeep.

The bottom line? Investing in eco-friendly and smart home filtration options isn’t just a trend; it’s a lifestyle change that promotes health and sustainability. So why not make the switch today? Your body and the planet will thank you!

The Importance of Certification in Water Filtration Products

Ever wondered why your water filter has a little sticker that looks like it belongs on a car? That’s the certification mark, and it’s not just for show. Certification in water filtration products is crucial for ensuring that what you’re drinking is safe and clean.

When municipalities invest in the filtration of water, they often rely on certified products to meet stringent safety standards. These certifications, such as those from NSF International or the Water Quality Association, act like a stamp of approval, confirming that the product has been rigorously tested for performance and safety.

Key Takeaway: Always look for certified filters to ensure they effectively remove contaminants like lead, chlorine, and bacteria. Your health deserves nothing less!

What Does Certification Mean?

Certification means a product has undergone specific testing to verify its claims about contaminant reduction and overall effectiveness. Think of it as a seal of trustworthiness in the vast world of water filtration systems. Without it, you’re basically rolling the dice on your drinking water quality.

Common Certifications to Look For

- NSF/ANSI 42: This certification indicates chlorine reduction and aesthetic improvements.

- NSF/ANSI 53: Focuses on health-related contaminants such as lead and volatile organic compounds (VOCs).

- NSF/ANSI 61: Ensures that materials used in the filtration system are safe for drinking water contact.

- WQA Gold Seal: Another reputable mark indicating rigorous testing and compliance with industry standards.

The Risks of Skipping Certification

If you think going for an unverified filter will save you some cash, think again! Uncertified filters can be ineffective at removing harmful substances, leading to potential health risks. Imagine sipping on what you thought was clean water only to find out it’s full of contaminants yikes!

The Growing Trend Towards Eco-Friendly Certifications

Sustainability is becoming paramount in the filtration industry. Many consumers are now looking for eco-friendly certifications, which not only guarantee safety but also promote environmentally responsible practices. Brands that focus on making their filters BPA-free or use recyclable materials are gaining traction among eco-conscious buyers.

The Bottom Line: Don’t Compromise on Safety

Your health is non-negotiable, especially when it comes to something as vital as drinking water. Investing in certified filtration systems means investing in your well-being. So next time you’re shopping for a home water filter or municipal treatment solution, remember: certification isn’t just a fancy label; it’s your assurance of clean drinking water.

Conclusion: Ensuring Clean Drinking Water Through Effective Filtration Methods

Clean drinking water is not just a luxury; it’s a necessity. With the alarming rise in water contamination, relying on outdated filtration methods is like using a flip phone in the age of smartphones. The filtration of water has evolved, and so should our systems.

Municipalities are stepping up their game to ensure that every drop served is safe and pure. Advanced technologies like reverse osmosis, UV water purification, and activated carbon filters are now the gold standard for effective water treatment. But here’s the kicker: not all systems are created equal. The right choice depends on your specific needs be it for municipal treatment facilities or home use.

Key Insight: Upgrading to a modern filtration system can reduce contaminants like lead, chlorine, and even bacteria, making your drinking water safer.

Understanding Your Options

The world of water filtration can be overwhelming, with options ranging from point-of-use solutions to whole-house systems. For municipalities, investing in robust technologies ensures compliance with safety regulations while providing residents with clean drinking water. On the other hand, homeowners can benefit from compact solutions like under-sink filters or countertop models that fit seamlessly into their lives.

A Closer Look at Filtration Techniques

- Sediment filtration: Perfect for removing larger particles from well water.

- Activated carbon filters: Excellent for reducing chlorine and improving taste.

- Reverse osmosis: A powerful method for removing heavy metals and contaminants.

- UV purification: Kills bacteria and viruses without chemicals safe and eco-friendly!

The interesting part? Many municipalities are now incorporating smart home filtration systems into their infrastructure, allowing residents to monitor their water quality through apps. This not only empowers users but also fosters trust between communities and their local governments.

The Future of Water Filtration

As we look ahead, emerging technologies will continue to reshape how we approach the filtration of water. Expect innovations such as portable filters for emergency situations or gravity-fed systems that require no power source ideal for rural areas or during natural disasters.

In conclusion, ensuring clean drinking water through effective filtration methods is no longer optional; it’s essential. Whether you’re part of a municipal system or simply concerned about your home’s drinking supply, embracing advanced filtration techniques will safeguard health and enhance quality of life. Don’t wait until you have a problem act now!

Overview of Filtration of Water in Municipal Systems

- Importance of water purification

- Role of filtration in water treatment

- Challenges faced by municipalities

Types of Water Filtration Methods

- Sediment Filtration

- Activated Carbon Filters

- Reverse Osmosis Systems

- UV Water Purification

- Ionic Exchange Filtration

- Alkaline Water Filters

Advanced Filtration Techniques for Enhanced Purity

- Carbon Block Filters

- Ceramic Water Filters

- Bacteria and Virus Removal Filters

Filtration Systems for Different Applications

- Muncipal Water Treatment Facilities

- Point of Use Filtration Solutions

Eco-Friendly and Smart Home Filtration Options

- BPA-Free Filters for Drinking Water Systems

The Importance of Certification in Water Filtration Products

Conclusion: Ensuring Clean Drinking Water Through Effective Filtration Methods

article blockquote,article ol li,article p,article ul li{font-family:inherit;font-size:18px}.featuredimage{height:300px;overflow:hidden;position:relative;margin-top:20px;margin-bottom:20px}.featuredimage img{width:100%;height:100%;top:50%;left:50%;object-fit:cover;position:absolute;transform:translate(-50%,-50%)}article p{line-height:30px}article ol li,article ul li{line-height:30px;margin-bottom:15px}article blockquote{border-left:4px solid #ccc;font-style:italic;background-color:#f8f9fa;padding:20px;border-radius:5px;margin:15px 10px}article div.info-box{background-color:#fff9db;padding:20px;border-radius:5px;margin:15px 0;border:1px solid #efe496}article table{margin:15px 0;padding:10px;border:1px solid #ccc}article div.info-box p{margin-bottom:0;margin-top:0}article span.highlight{background-color:#f8f9fb;padding:2px 5px;border-radius:5px}article div.info-box span.highlight{background:0 0!important;padding:0;border-radius:0}article img{max-width:100%;margin:20px 0}