Top OEMs for Digestion Systems

1. Introduction

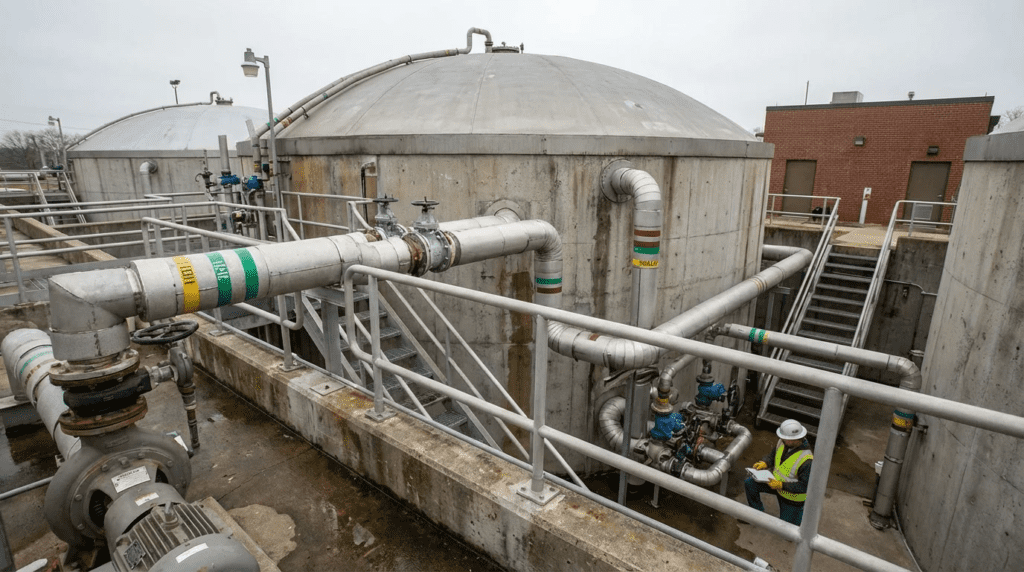

In the hierarchy of municipal and industrial wastewater treatment processes, digestion systems occupy a critical role at the intersection of solids handling, pathogen reduction, and energy recovery. As facilities transition from traditional treatment plants to Water Resource Recovery Facilities (WRRFs), the anaerobic or aerobic digester transforms from a simple sludge stabilization tank into a complex bio-energy reactor. For municipal consulting engineers and plant superintendents, the specification and selection of digestion equipment—comprising mixing systems, covers, heating loops, and gas handling integration—define the facility’s long-term operational expenditure (OPEX) and regulatory compliance profile.

Digestion systems are primarily tasked with the stabilization of primary and waste activated sludge (WAS). The biological process breaks down volatile solids, reducing the total mass of solids requiring disposal while generating biogas (in anaerobic applications) that can be harvested for heat or electrical power. The effectiveness of this process is governed by the “Three T’s” of digestion: Time (Solids Retention Time), Temperature (Mesophilic or Thermophilic regimes), and Turbulence (Mixing). While the biology is natural, the mechanical systems that sustain these conditions are engineered.

The selection of Original Equipment Manufacturers (OEMs) for digestion systems is not merely a purchase of tanks and mixers; it is the selection of a process technology partner. The digestion complex is often the most expensive capital asset on a treatment plant site, with a design life exceeding 20 to 30 years. Consequently, the engineering pedigree of the equipment provider is paramount. Factors such as the structural integrity of steel covers in corrosive H2S environments, the fluid dynamic efficiency of mixing systems in non-Newtonian sludge, and the thermal efficiency of heat exchangers directly impact the facility’s ability to meet EPA Class A or Class B biosolids regulations.

This article provides a comprehensive, engineer-focused analysis of the leading OEMs in the digestion system market. It avoids marketing rhetoric to focus on mechanical reliability, process flexibility, and the engineering considerations required to integrate these massive systems into modern wastewater infrastructure.

2. How to Select This Process Equipment

Selecting a digestion system requires a holistic engineering approach that balances process biology with mechanical robustness. Unlike simpler unit processes, a digester is a system of systems. Engineers must evaluate the integration of covers, mixers, and heating equipment to ensure they function as a cohesive unit under varying loading conditions. The following technical criteria are essential for specifying and selecting digestion equipment.

Process Function and Performance Requirements

The primary metric for digestion performance is Volatile Solids Reduction (VSR). Regulatory standards, such as the EPA 503 rule in the United States, mandate specific VSR targets (typically exceeding 38%) and pathogen reduction levels to classify biosolids for land application. The OEM’s equipment must guarantee sufficient homogenization of the tank contents to prevent “dead zones” where solids accumulate and short-circuiting where raw sludge exits before adequate retention time.

Engineers must define the intended operating regime:

- Mesophilic Digestion: Operating between 35°C and 39°C. This is the industry standard, offering stable operation with moderate energy requirements. Equipment selected must maintain tight temperature bands (±1°C) to prevent biological upset.

- Thermophilic Digestion: Operating between 50°C and 57°C. This regime offers faster reaction rates and higher pathogen kill (Class A potential) but requires more robust heating systems, insulation, and materials resistant to higher corrosion rates and thermal expansion.

- Acid/Gas Phased Digestion: Advanced configurations separating acidogenesis and methanogenesis phases, requiring specialized tankage and transfer pumping equipment.

Mixing Technologies and Fluid Dynamics

Mixing is the single most critical mechanical subsystem. Sludge in a digester exhibits thixotropic and non-Newtonian fluid properties, meaning its viscosity changes with shear rate. Improper mixing leads to grit accumulation (reducing active volume), thermal stratification, and foaming.

- Pumped Mixing (Jet or Nozzle): Utilizes external or internal chopping pumps to recirculate sludge through nozzles. Strengths include the ability to chop rags and external maintenance access. However, nozzle wear and energy intensity are considerations.

- Mechanical Draft Tube Mixers: Utilize a vertical tube with an impeller to create a vertical circulation loop. These are highly efficient for keeping solids in suspension but can be susceptible to ragging if not properly designed with reversing capabilities or chopper blades.

- Linear Motion Mixers: Use a vertical plunger or disc to pulse energy into the tank. This low-energy approach is effective for maintaining homogeneity but may have limitations in re-suspending settled grit in heavy loading scenarios.

- Gas Mixing: Injects compressed biogas at the bottom of the tank (lances or floor diffusers). While historically common, many utilities are moving away from floor-mounted gas systems due to maintenance difficulties (requiring tank entry) and precipitant clogging issues.

Cover Technologies and Gas Containment

The digester cover serves three functions: odor containment, anaerobic condition maintenance, and gas storage.

- Fixed Steel Covers: Rigid structures welded to the tank. They maintain a constant volume but require upstream gas holder management to handle variable gas production.

- Floating Steel Covers: The traditional “Gasholder” design. These covers float on the sludge or gas bubble, providing variable volume storage. They require precise ballasting and guide rail systems to prevent tilting or binding (corning).

- Dual-Membrane Covers: Consist of an inner gas-holding membrane and an outer protective membrane kept inflated by air blowers. These offer significant cost savings and corrosion resistance compared to steel but have a shorter lifecycle (10-15 years vs. 20-30+ for steel) and require careful pressure control logic.

Thermal Energy and Heat Exchange

Maintaining the biological sweet spot requires offsetting thermal losses through tank walls and heating incoming raw sludge. OEMs typically integrate:

- Tube-in-Tube Heat Exchangers: Excellent for sludge with high debris content due to large flow paths.

- Spiral Heat Exchangers: Offer high thermal transfer efficiency and compact footprint but can be prone to fouling if screening is inadequate.

- Water Bath Heaters: Indirect heating methods that provide thermal inertia but slower response times.

Materials of Construction and Corrosion Control

The headspace of an anaerobic digester is a highly aggressive environment containing hydrogen sulfide (H2S), carbon dioxide, and moisture—a perfect recipe for sulfuric acid formation.

- Steel: Carbon steel covers require high-performance epoxy coating systems. 316L Stainless steel is increasingly specified for wetted parts, draft tubes, and critical structural elements, despite higher capital cost, to reduce lifecycle maintenance.

- Concrete: Tank walls are typically concrete. The interface between the steel cover skirt and the concrete wall is a common failure point requiring specialized liners or stainless steel embedment plates.

Operational Integration

The digestion system does not operate in a vacuum. It must integrate with:

- Screening: Poor upstream screening allows rags to enter the digester, fouling mixers and heat exchangers.

- Grit Removal: Grit accumulation reduces active volume. Some OEM mixing systems are specifically designed to suspend grit for removal, while others require periodic tank cleaning.

- Dewatering: The characteristics of digested sludge affect polymer consumption and cake solids in downstream dewatering equipment.

3. Comparison Table

The following table compares the four primary OEMs dominating the North American digestion system market. Engineers should use this table to align project-specific constraints—such as retrofit geometry, preference for cover type, or mixing philosophy—with the vendor’s core competencies. This high-level overview highlights the distinctions in their technological approaches rather than ranking them, as “best” is situational.

| OEM Name | Core Technologies | Engineering Strengths | Best-Fit Applications | Considerations |

|---|---|---|---|---|

| WesTech Engineering | Duo-Deck Covers, CleanSeam Construction, Extreme Duty Mixers, Spiral Heat Exchangers | Exceptional structural engineering for steel covers; focus on “turnkey” system delivery including heating and mixing; robust mechanical draft tube designs. | Municipalities requiring robust steel cover retrofits; projects valuing single-source system responsibility; plants with heavy ragging concerns. | Premium heavy-duty designs may carry higher initial capital costs compared to membrane-only solutions. |

| Ovivo | Eimco® Heritage, LM (Linear Motion) Mixers, Ultrastore Membrane Holders, Draft Tube Mixers | Extensive installed base (Eimco legacy); low-energy mixing options (Linear Motion); deep expertise in both aerobic and anaerobic process biology. | Energy-conscious facilities targeting low OPEX mixing; large-scale municipal plants; retrofits of legacy Eimco equipment. | Linear motion mixing requires careful evaluation for heavy grit applications; membrane covers have different maintenance protocols than steel. |

| Evoqua Water Technologies | Envirex® Heritage, JetMix Vortex Systems, Dystor® Gas Holder Systems, Floating Covers | Strong portfolio of jet mixing technologies; pioneered the dual-membrane gas holder market (Dystor); massive historical archive of installations. | Facilities preferring hydraulic/jet mixing over mechanical draft tubes; sites needing maximized gas storage via membrane solutions. | Jet mixing involves external pumps which require space and pump maintenance; nozzle placement is critical for hydraulic efficiency. |

| Walker Process Equipment | GasLifter® Systems, Rolling & Fixed Covers, Mechanical Mixers, Heat Exchangers | Conservative, heavy-duty structural designs; long history of reliable floating cover ballasting systems; simple, rugged mechanical components. | Municipal utilities prioritizing longevity and traditional, proven mechanical designs; direct replacements for legacy Walker installations. | Tendency toward traditional designs rather than experimental technologies; heavy steel focus. |

4. Top OEM Manufacturers

WesTech Engineering

WesTech Engineering is an employee-owned company that has firmly established itself as a premier provider of digestion systems, particularly noted for its structural steel capabilities and holistic system integration. Unlike manufacturers that focus solely on one component, WesTech typically engineers the entire digestion loop: the cover, the mixer, and the heating system.

Engineering Characteristics:

WesTech is renowned for its **Duo-Deck** floating covers. These covers utilize a truss-type design that provides exceptional structural rigidity, minimizing the risk of tipping or binding during operation—a common failure mode in large-diameter digesters. Their manufacturing process often includes **CleanSeam** welding, which ensures smooth internal surfaces to reduce corrosion initiation sites.

On the mixing side, WesTech offers mechanical draft tube mixers designed for extreme duty. These units are engineered to handle high-viscosity sludge and include reversing impellers to clear ragged material. Their approach to heat exchange often utilizes spiral geometries, which provide high heat transfer coefficients in a compact footprint, critical for retrofit projects with limited mechanical room space.

Key Differentiator:

WesTech excels in complex retrofit scenarios where new covers must fit existing, often out-of-round concrete tanks. Their field erection teams and engineering support are highly regarded for managing the interface between civil works and mechanical equipment.

Ovivo

Ovivo brings a massive historical pedigree to the market, incorporating the legacies of Eimco and Dorr-Oliver. This extensive archive of installations gives Ovivo a unique advantage in understanding long-term equipment lifecycle and failure modes. Ovivo offers a diverse portfolio ranging from traditional steel covers to advanced membrane gas storage.

Engineering Characteristics:

A standout technology in Ovivo’s portfolio is the **LM (Linear Motion) Mixer**. Unlike rotational mixers, the LM mixer uses a vertical oscillating disc to generate a wave of energy that keeps solids in suspension. This technology consumes significantly less power than traditional mechanical or pumped mixing, directly reducing the parasitic load of the digestion process. For gas storage, Ovivo promotes the **Ultrastore** membrane gas holder, a sphere-within-sphere design that separates gas storage from the liquid level, simplifying control.

Ovivo also supplies traditional mechanical draft tube mixers and fixed/floating steel covers, allowing engineers to select the technology that best fits the specific hydraulic profile of the plant.

Key Differentiator:

The sheer breadth of their mixing portfolio allows for unbiased application engineering. They can supply linear motion for energy savings or violent mechanical mixing for difficult, grit-heavy sludges, depending on the client’s specific rheology.

Evoqua Water Technologies

Evoqua (now part of Xylem) holds the lineage of Envirex and PFT (Pacific Flush Tank), names that appear on thousands of digester drawings from the mid-20th century. Evoqua is a dominant force in hydraulic mixing and membrane cover technologies.

Engineering Characteristics:

Evoqua is a leader in **Jet Mixing**. Their systems utilize external chopper pumps to draw sludge from the tank and recirculate it through floor-mounted nozzles. This creates a toroidal mixing pattern that is highly effective at homogenizing the tank contents and resuspending settled solids. Because the moving parts (pumps) are external to the tank, maintenance can be performed without taking the digester out of service—a major operational advantage.

In terms of covers, Evoqua’s **Dystor®** gas holder system is a market standard for dual-membrane covers. It provides substantial gas storage volume and operates at lower pressures, suitable for various downstream gas utilization equipment.

Key Differentiator:

The ability to maintain mixing equipment without opening the tank (via external pumps) is a significant safety and operational benefit, particularly for utilities with strict confined space entry protocols.

Walker Process Equipment

Walker Process Equipment is synonymous with durability and traditional wastewater engineering. A division of McNish Corporation, Walker Process focuses on heavy-duty custom engineering. Their equipment is often found in facilities that prioritize 50-year design horizons and robust structural steelwork.

Engineering Characteristics:

Walker Process is best known for its **GasLifter®** and mechanical draft tube mixing systems. Their designs prioritize torque capability and structural mass, ensuring that mixers can power through heavy sludge loading events without tripping on overload. Their floating covers feature robust roller guide systems and ballast engineering designed to prevent the “tipping” issues that plagued early digester designs.

While they may be less aggressive in marketing novel low-energy concepts compared to some competitors, their adherence to conservative design safety factors makes them a favorite among risk-averse municipal engineers. Their heat exchangers are typically concentric tube designs, which, while larger than spirals, are incredibly difficult to clog and easy to clean.

Key Differentiator:

Walker Process is often the “safe specification.” Their adherence to AWWA and structural standards is rigorous, ensuring that the physical asset (steel and iron) outlasts the mechanical components.

5. Application Fit Guidance

Selecting the right OEM often depends on the specific constraints of the facility type and the project drivers.

Municipal Wastewater (Large Scale > 20 MGD)

For large facilities, energy efficiency and gas management are paramount.

- Ovivo is often favored here for the LM Mixer’s energy savings, which compound significantly at scale.

- Evoqua’s Dystor covers are frequently selected to maximize biogas storage for cogeneration engines without building separate gas spheres.

Municipal Wastewater (Small to Mid Scale)

For smaller plants, simplicity and “set it and forget it” reliability are key.

- Walker Process and WesTech are strong fits here. Their mechanical draft tube mixers are simple to understand and operate. The robustness of steel covers (vs. membranes) appeals to operators who do not want to manage blower systems for membrane inflation.

Retrofit Installations

Retrofitting 50-year-old tanks presents unique challenges: out-of-round concrete, existing piping penetrations, and inability to drain tanks fully during construction.

- WesTech has a dedicated focus on retrofits, with engineering teams skilled at designing covers that accommodate irregular tank geometries.

- Evoqua’s Jet Mixing is excellent for retrofits where structural modifications to the digester roof (to support heavy mechanical mixers) are not feasible. piping can be routed through existing manways or core-drilled walls.

Industrial Anaerobic Digestion

Industrial waste (food and beverage, dairy) often has much higher volatile solids loading and different acidification rates.

- WesTech and Ovivo have strong industrial groups capable of modifying municipal designs to handle the aggressive pH swings and high-rate gas production typical of industrial digesters.

6. Engineer & Operator Considerations

Beyond the catalog specifications, the long-term success of a digestion system relies on practical operational factors.

Struvite and Vivianite Scaling

Digestion releases magnesium, ammonium, and phosphate, leading to the formation of Struvite (Magnesium Ammonium Phosphate). This rock-like scale clogs pipes, heat exchangers, and freezes mixers.

- Engineer Note: When selecting heat exchangers, tube-in-tube designs (Walker/WesTech) are generally easier to mechanically clean (pigging) than spiral exchangers.

- Operator Note: Jet mixing nozzles (Evoqua) must be placed carefully to avoid low-velocity zones where struvite precipitates.

Ragging and Screening

No digester mixer is immune to rags if upstream screening is poor. However, the failure mode differs.

- Mechanical Mixers (WesTech/Walker/Ovivo): Rags accumulate on the impeller. Reversing capabilities are essential specs.

- Jet Mixing (Evoqua): Rags clog the external pump. Chopper pumps are mandatory here.

Safety and Gas Handling

Digester gas (Biogas) is explosive and contains toxic H2S.

- Cover Seals: Liquid seals on floating covers require constant water level maintenance and freeze protection. Membrane covers require constant blower operation to maintain pressure; power redundancy is critical.

- Foaming: Rapid changes in loading can cause foaming. Fixed covers can be structurally damaged if foam blocks gas withdrawal piping (over-pressurization). Floating covers are generally more forgiving of foam events.

Maintenance Access

- Internal Maintenance: Draft tube mixers and gas lances require the tank to be drained and degassed for service—a major operation occurring every 5-10 years.

- External Maintenance: Jet mix pumps and Linear Motion drive heads (Ovivo) allow for maintenance without tank entry. This significantly reduces lifecycle safety risks and costs.

7. Conclusion

The selection of a digestion system OEM is a strategic decision that dictates the energy neutrality potential and biosolids compliance of a wastewater facility. There is no single “best” manufacturer; rather, there are optimized matches between facility constraints and OEM engineering philosophies.

WesTech Engineering and Walker Process Equipment represent the pinnacle of structural robustness and traditional mechanical reliability, ideal for facilities prioritizing long service life and heavy-duty steel construction. Ovivo offers a bridge between heritage reliability and modern energy efficiency with their Linear Motion technology, suitable for energy-conscious utilities. Evoqua (Xylem) excels in hydraulic flexibility and advanced gas storage solutions, offering distinct advantages for retrofit applications and facilities prioritizing external maintenance access.

Engineers must move beyond first-cost comparisons and evaluate the Total Cost of Ownership (TCO), factoring in mixing energy, cover maintenance, heat transfer efficiency, and the cost of tank cleaning over a 20-year horizon. By aligning the process goals (VSR, gas production) with the specific mechanical strengths of these Top OEMs, utilities can build resilient, high-performance resource recovery systems.