Passaic Valley Sewerage Commission Newark

Location: Newark, Essex County, New Jersey

Operating Authority: Passaic Valley Sewerage Commission

Design Capacity: 330 MGD (Average) / 720 MGD (Peak)

Service Area: 48 Municipalities across 5 Counties

1. INTRODUCTION

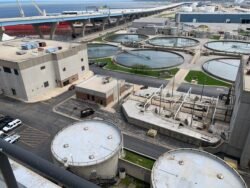

The Passaic Valley Sewerage Commission (PVSC) Newark Bay Treatment Plant is one of the largest wastewater treatment facilities in the United States and the largest in the Northeast. Located in the Ironbound section of Newark, New Jersey, this massive infrastructure asset provides critical sanitation services for approximately 1.5 million residents across 48 municipalities in Bergen, Essex, Hudson, Passaic, and Union counties. The facility manages a massive service area responsible for a significant portion of the state’s industrial and residential wastewater.

Commissioned originally to address pollution in the Passaic River, the modern treatment plant has a design capacity of 330 million gallons per day (MGD) and a wet-weather peak capacity of 720 MGD. Following the catastrophic impact of Superstorm Sandy in 2012, PVSC has become a focal point for engineering resilience, currently undertaking over $500 million in hardening and resiliency upgrades. The facility utilizes a high-purity oxygen activated sludge process to treat high-strength influent within a constrained urban footprint, discharging high-quality effluent into the Upper New York Bay via a deep-water tunnel.

2. FACILITY OVERVIEW

A. Service Area & Coverage

PVSC operates as a regional utility serving a densely populated and highly industrialized corridor of Northern New Jersey. The service district encompasses approximately 100 square miles, including major urban centers like Newark, Jersey City, Paterson, and Elizabeth. The collection system is vast, comprising over 22 miles of main interceptor sewers ranging up to 12 feet in diameter. Due to the age of the infrastructure in the service area, a significant portion of the collection system consists of Combined Sewer Systems (CSS), which convey both sanitary flow and stormwater, necessitating aggressive wet-weather flow management strategies at the plant.

B. Operational Capacity

The facility is engineered to handle substantial hydraulic volatility:

- Design Average Flow: 330 MGD

- Current Average Daily Flow: ~240 MGD

- Peak Wet Weather Flow: 720 MGD

Historically, flow rates are heavily influenced by precipitation events. During dry weather, the plant operates well within capacity; however, during heavy rainfall, the combined sewer system directs massive volumes to the headworks. The facility utilizes a comprehensive wet weather management plan to maximize treatment through the secondary system and blend excess flows in compliance with regulatory mandates.

C. Discharge & Compliance

Treated effluent is discharged into the Upper New York Bay near Robbins Reef via a 12-foot diameter tunnel outfall. The discharge is regulated under the New Jersey Pollutant Discharge Elimination System (NJPDES). The receiving waters are part of the complex New York/New Jersey Harbor Estuary. Strict compliance is required regarding Total Suspended Solids (TSS), Biochemical Oxygen Demand (BOD), and seasonal disinfection to protect the estuary’s ecosystem and recreational waters.

3. TREATMENT PROCESS

The PVSC facility employs a pure-oxygen activated sludge secondary treatment process. This technology was selected to handle high organic loading rates within a limited site footprint compared to conventional air-activated sludge systems.

A. Preliminary Treatment

Raw wastewater enters the facility via the main interceptor. Preliminary treatment is critical for protecting downstream equipment from the debris common in combined sewer systems.

- Screening: Twelve mechanical bar screens remove large debris, rags, and plastics. The screenings are washed, compacted, and transported off-site for disposal.

- Grit Removal: Following screening, flow enters aerated grit chambers where velocity is reduced to allow inorganic solids (sand, gravel, coffee grounds) to settle.

- Pumping: The Main Pumping Station lifts the wastewater from the deep interceptor level to the primary clarifiers, providing the hydraulic head necessary for gravity flow through the remainder of the plant.

B. Primary Treatment

The facility utilizes 12 rectangular primary sedimentation tanks. These tanks reduce flow velocity to allow settleable organic solids to drop to the bottom as primary sludge, while grease and oils float to the surface for skimming.

- Retention Time: Approximately 1.5 to 2 hours at average flow.

- Removal Efficiency: Typically removes 30-35% of BOD and 50-60% of TSS.

- Sludge Handling: Primary sludge is pumped directly to the solids handling facility for thickening and dewatering.

C. Secondary Treatment (Pure Oxygen Activated Sludge)

The biological heart of the PVSC plant is the oxygenation tanks. Unlike conventional systems that blow ambient air into the water, PVSC utilizes a High Purity Oxygen (HPO) system (UNOX technology).

- Oxygen Generation: The facility utilizes a Cryogenic Oxygen Plant on-site to generate pure oxygen.

- Bioreactors: Covered aeration tanks maintain a high partial pressure of oxygen, allowing for higher Mixed Liquor Suspended Solids (MLSS) concentrations and faster reaction rates. This allows the plant to treat high BOD loads in a smaller volumetric footprint.

- Clarification: The mixed liquor flows to 12 secondary clarifiers where the biological biomass settles. Return Activated Sludge (RAS) is recycled to the oxygenation tanks, while Waste Activated Sludge (WAS) is sent to solids processing.

D. Disinfection

Effluent from the secondary clarifiers undergoes disinfection to eliminate pathogenic microorganisms.

- Primary Disinfectant: Sodium Hypochlorite (15% solution) is injected into the effluent.

- Contact Tanks: Two chlorine contact tanks provide sufficient detention time for pathogen inactivation.

- Dechlorination: To protect aquatic life in the harbor, the effluent is dechlorinated using Sodium Bisulfite prior to entering the outfall tunnel.

F. Solids Handling

PVSC processes massive quantities of residuals, managing both its own sludge and liquid waste accepted from merchant customers (Liquid Waste Acceptance Program).

- Thickening: Gravity thickening for primary sludge and gravity belt thickening for waste activated sludge.

- Dewatering: The facility utilizes high-capacity decanter centrifuges to dewater the thickened sludge into a “cake” with higher solids content.

- Disposal: Historically, PVSC utilized Zimpro wet air oxidation and lime stabilization. Currently, the primary disposal method involves dewatering and off-site disposal/beneficial reuse via truck or rail.

4. INFRASTRUCTURE & FACILITIES

A. Physical Plant

The site spans over 140 acres in an industrial zone adjacent to the New Jersey Turnpike and Newark Liberty International Airport. The complex includes the massive administrative building, the extensive laboratory (certified for a wide range of parameters), maintenance shops, and the dock facilities on Newark Bay utilized for sludge vessel operations (historically) and equipment delivery.

B. Energy Systems & Resiliency

Energy security is the facility’s highest priority following the 2012 grid failure during Superstorm Sandy.

- Standby Power Generation Facility (SPGF): A cornerstone of the new infrastructure, this plant features three 11.3-megawatt dual-fuel (natural gas/diesel) turbine generators capable of powering the entire treatment plant during a grid outage.

- Energy Efficiency: The switch to pure oxygen allows for more efficient dissolution of oxygen per unit of energy compared to standard blowers, though the cryogenic plant itself is a significant load.

C. Odor Control

Given the proximity to the Ironbound residential community, odor control is paramount. The primary clarifiers and sludge processing areas are covered or enclosed. Foul air is captured and routed through multi-stage chemical scrubbers and activated carbon adsorption systems to remove hydrogen sulfide and mercaptans before release.

5. RECENT UPGRADES & MAJOR PROJECTS

Since 2013, PVSC has been executing one of the most ambitious resiliency programs in the wastewater sector, largely driven by the damages sustained during Hurricane Sandy. The PVSC Resiliency Program represents an investment exceeding $500 million, largely funded by FEMA reimbursement and mitigation grants.

PROJECT SPOTLIGHT: Standby Power Generation Facility (SPGF)

Budget: ~$180 Million

Status: Construction (Near Completion/Commissioning)

Scope: Construction of a dedicated on-site power plant to ensure the facility never loses power during grid failures, preventing the release of untreated sewage.

- Installation of three (3) Solar Titan 130 Gas Turbine Generators (34 MW total capacity).

- Construction of a resilient, elevated building to house the generation equipment above the 500-year flood elevation.

- Integration with local utility (PSE&G) for black start capability.

Flood Wall Protection System (Current)

- Budget: ~$200 Million

- Scope: Construction of a concrete flood wall encompassing the entire 140-acre treatment plant. The wall is designed to established FEMA flood elevations plus freeboard for sea-level rise.

- Features: Includes passive flood gates at facility entrances that deploy automatically during surge events.

Phase V Rehabilitation (2018-2022)

- Budget: ~$90 Million

- Scope: Rehabilitation of the primary settling tanks and secondary clarifiers. Included replacement of chain-and-flight mechanisms, concrete repair, and upgrade of sludge pumping systems to improve reliability and solids capture.

6. REGULATORY COMPLIANCE & ENVIRONMENTAL PERFORMANCE

A. Permit Requirements

PVSC operates under NJPDES Permit No. NJ0021016. As a facility discharging into the shared waters of the NY/NJ Harbor, it faces strict scrutiny regarding nitrogen loading and floatables. The facility is also a key partner in the Long Term Control Plan (LTCP) to address Combined Sewer Overflows (CSOs) in the region.

B. Compliance History

PVSC generally maintains a strong compliance record regarding effluent limitations for BOD and TSS. The primary compliance challenges historically stem from wet weather events where influent volume exceeds secondary treatment capacity. The facility utilizes a wet weather bypass protocol authorized under the permit, which involves primary treatment and disinfection of excess flows before blending with secondary effluent.

C. Environmental Stewardship

PVSC runs an active “River Restoration Program,” deploying skimmer vessels to remove floating debris and drift wood from the Passaic River and Newark Bay. To date, this program has removed thousands of tons of debris, significantly improving the aesthetics and navigability of the local waterways.

10. TECHNICAL SPECIFICATIONS SUMMARY

| Parameter | Specification |

|---|---|

| Facility Type | High Purity Oxygen Activated Sludge |

| Design Capacity (Average) | 330 MGD |

| Peak Wet Weather Capacity | 720 MGD |

| Population Served | ~1.5 Million |

| Service Area | ~100 Square Miles (48 Municipalities) |

| Aeration Method | Pure Oxygen (Cryogenic Generation / Surface Aerators) |

| Primary Treatment | 12 Rectangular Clarifiers |

| Secondary Treatment | 12 Secondary Clarifiers |

| Disinfection | Sodium Hypochlorite (Chlorination/Dechlorination) |

| Biosolids Processing | Gravity Thickening, Decanter Centrifuges |

| Receiving Water Body | Upper New York Bay (via Tunnel Outfall) |

| Resiliency Elevation | Protected to FEMA 500-Year Flood + Sea Level Rise |

| Year Commissioned | 1924 (Original), 1980s (Major Expansion) |

12. FAQ SECTION

Technical & Professional Questions

1. What is the peak hydraulic capacity of PVSC?

The plant is rated for a peak wet weather flow of 720 MGD. Flows beyond secondary capacity are treated via primary settling and disinfection before blending.

2. Does PVSC perform nutrient removal?

The current configuration focuses on Carbonaceous BOD (CBOD) removal. While nitrogen monitoring is conducted, the plant is not currently configured for full Biological Nutrient Removal (BNR), though future regulatory changes in the NY/NJ Harbor Estuary Program may impact this.

3. How does the facility manage power reliability?

PVSC is commissioning a dedicated 34 MW Standby Power Generation Facility (SPGF) comprising three gas turbines, ensuring 100% operational capability independent of the commercial grid.

4. Does the facility accept hauled waste?

Yes, PVSC operates a Liquid Waste Acceptance (LWA) program, accepting non-hazardous liquid waste (greywater, leachate, sludge) from external customers for treatment, generating revenue to offset ratepayer costs.

Public Interest Questions

5. Why is the plant located in Newark?

The location was chosen in the early 20th century as the terminus of the main interceptor sewer following the natural gravity drainage of the Passaic River valley.

6. What happens during a hurricane?

Following Superstorm Sandy, PVSC has installed flood walls and backup generators. The plant is designed to remain operational during major storm surges to prevent sewage backups in member communities.

7. How is the “Newark Bay smell” managed?

PVSC utilizes extensive odor control scrubbers and covers primary treatment tanks. They maintain a 24-hour odor hotline for community complaints.