Xylem Wedeco vs Ozonia BioGas Equipment: Comparison & Best Fit

Introduction

In the high-stakes environment of municipal and industrial wastewater treatment, few decisions impact long-term operational costs (OPEX) as significantly as the selection of oxidation and gas handling systems. Engineers frequently underestimate the lifecycle implications of dielectric technologies and cooling requirements when specifying ozone generation systems for disinfection, micropollutant removal, or sludge handling. A specification error here does not just result in a change order; it can lead to a 15-20% variance in specific power consumption (kWh/kg O3) over a 20-year asset life.

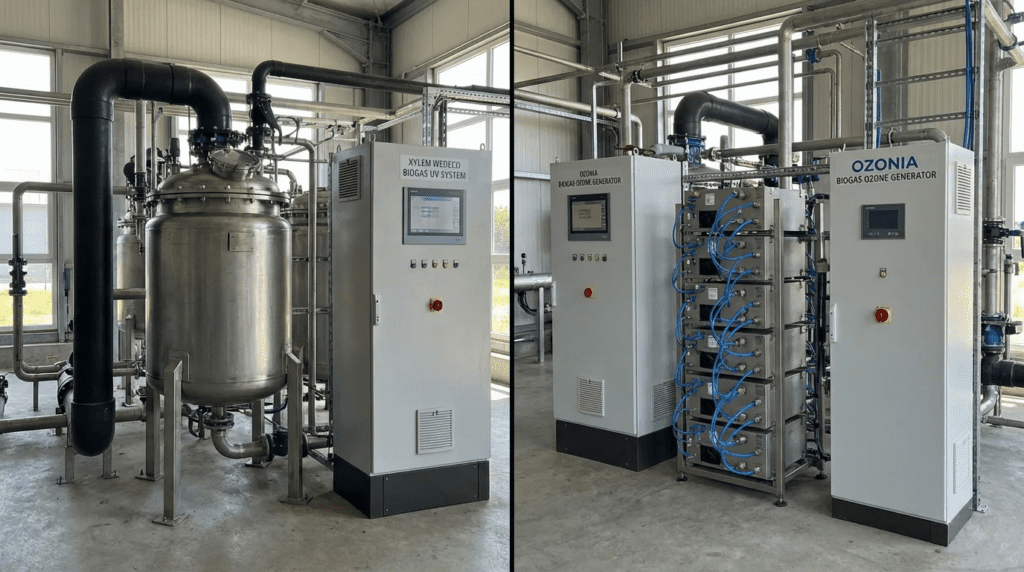

When evaluating Xylem Wedeco vs Ozonia BioGas Equipment: Comparison & Best Fit, engineers are essentially comparing two different engineering philosophies regarding dielectric barrier discharge (DBD), power supply architecture, and vessel geometry. While both manufacturers—Xylem (Wedeco) and Suez/Veolia (Ozonia)—dominate the market, their approaches to electrode protection, cooling efficiency, and turndown capabilities differ materially. These systems are critical in applications ranging from potable water disinfection and wastewater tertiary treatment to specialized biogas applications like H2S reduction and sludge lysis for enhanced digestion.

Typically, these systems operate in harsh, humidity-controlled environments where component reliability is paramount. Poor selection often manifests as frequent dielectric failures, harmonic distortion issues on the plant electrical grid, or inability to meet peak dosing requirements during high-flow events. This article provides a technical, unbiased analysis to help engineers navigate the specification and selection process, focusing on the mechanical and electrical nuances that distinguish these industry leaders.

How to Select and Specify Ozone & BioGas Systems

Selecting between major OEMs requires moving beyond the brochure and analyzing the core engineering constraints of the project. The decision framework for Xylem Wedeco vs Ozonia BioGas Equipment: Comparison & Best Fit should be driven by the specific process objectives, whether that is log-inactivation of pathogens or stoichiometric oxidation of sulfides.

Duty Conditions & Operating Envelope

The first step in specification is defining the operating envelope. Engineers must determine the required ozone concentration (% by weight) relative to the feed gas capability (LOX vs. PSA). Wedeco and Ozonia units have different efficiency curves (“knees”) where power consumption spikes relative to concentration.

- Flow and Dosage: Define the peak instantaneous flow and the average daily flow. Ozone systems have turndown limits (typically 10:1 or 20:1). If the plant experiences extreme low-flow conditions (e.g., initial startup years), a single large generator may trip on low gas flow or overheat.

- Gas Pressure: Check the back-pressure requirements of the contactors. Deep U-tube contactors or pressurized biogas lines require higher discharge pressures (20–40 psig). Ensure the generator vessel is ASME coded for the requisite pressure plus a safety margin.

- Turndown Requirements: Specify whether the modulation will be achieved via Power Supply Unit (PSU) frequency/voltage manipulation or by banking multiple cells. Linear turndown prevents over-dosing and wasted oxygen.

Materials & Compatibility

The “heart” of these systems is the dielectric—the component that facilitates the corona discharge. This is the primary point of divergence in the Xylem Wedeco vs Ozonia BioGas Equipment: Comparison & Best Fit analysis.

- Dielectric Material: Wedeco typically utilizes a glass dielectric (Effizon technology) which is highly resistant to thermal shock and mechanical stress. Ozonia frequently employs ceramic or proprietary glass-metal composites (IGS technology) which allows for very high power densities.

- Vessel Construction: The ozone vessel must be 316L stainless steel at a minimum. For biogas applications where H2S or other corrosives may be present in the ambient air or process stream, 316Ti or higher alloy cladding may be required.

- Gasket Compatibility: Ozone is an aggressive oxidant. All wetted seals must be PTFE (Teflon) or Kalrez. EPDM and Viton will degrade rapidly. This is a critical check item during submittal review.

Hydraulics & Process Performance

Efficiency in ozone generation is measured in specific power consumption. Engineers should request performance curves showing kWh/kg O3 at various concentrations (e.g., 10wt%, 12wt%).

- Cooling Water Hydraulics: 90% of the energy into an ozone generator becomes heat. The cooling water loop (closed vs. open) is critical. Specify the maximum $Delta T$ and pressure drop allowed across the vessel.

- Gas Flow Hydraulics: High gas flow with low concentration requires larger piping and diffusers. Low gas flow with high concentration (12-14%) reduces pipe size but increases generator stress.

Installation Environment & Constructability

Space is often a premium in retrofit applications.

- Footprint: Compare the skid density. Wedeco units often have a longer horizontal footprint due to tube length, while Ozonia units can be more compact but may require more vertical clearance for maintenance access.

- Tube Pull Space: This is a critical architectural constraint. A 3-meter vessel requires 3+ meters of clearance on one end to remove electrodes for maintenance. Failing to account for this in the building layout is a catastrophic design error.

- HVAC Requirements: These units generate significant ambient heat. The electrical room housing the PSUs must be conditioned to prevent component failure.

Reliability, Redundancy & Failure Modes

Municipal specifications typically require N+1 redundancy. However, the definition of “N” matters.

- Dielectric Failure Mode: In older designs, one dielectric failure could trip the whole vessel. Modern Wedeco and Ozonia systems utilize individual fusing. If one tube fails, the fuse blows, and the unit continues to operate at slightly reduced capacity.

- Power Supply Redundancy: Look for modular PSU designs. If one inverter module fails, can the others pick up the load, or does the entire generator shut down?

- MTBF: Mean Time Between Failure for the dielectrics should exceed 10 years under normal operation.

Lifecycle Cost Drivers

CAPEX is the tip of the iceberg. The 20-year Net Present Value (NPV) analysis usually favors efficiency over initial price.

- Power Consumption: This is the largest OPEX driver. A difference of 0.5 kWh/kg O3 translates to hundreds of thousands of dollars over the asset life.

- Oxygen Usage: Higher concentration efficiency means less Liquid Oxygen (LOX) purchased or smaller PSA compressors required.

- Maintenance Labor: Consider the labor hours required to clean or replace dielectrics. Glass dielectrics generally require less frequent cleaning than older ceramic designs, but specific manufacturer guidelines vary.

Comparison Tables

The following tables provide a side-by-side analysis of Xylem Wedeco and Ozonia technologies. These comparisons assume current generation municipal-scale equipment (e.g., Wedeco PDO/SMO series vs. Ozonia M/CFS series) typically utilized in water treatment and biogas-related oxidation applications.

| Feature / Parameter | Xylem Wedeco (e.g., PDO/SMO Series) | Ozonia (Suez/Veolia) (e.g., M / CFS Series) | Engineering Implication |

|---|---|---|---|

| Dielectric Technology | Effizon® evo 2G (Glass core, stainless steel mesh). | IGS / AT (Intelligent Gap System). Often Ceramic or Hybrid Glass/Metal. | Glass is robust and maintenance-free (no cleaning required usually). Ceramic allows high power density but can be more brittle. |

| Cooling Configuration | Typically horizontal vessel; water outside tubes. | typically horizontal; high-velocity flow design. | Both require strict temperature control. Wedeco’s glass has high thermal shock resistance. |

| Power Supply (PSU) | IGBT-based, variable frequency. Very low harmonic distortion (<5% THD). | IGBT-based, resonance technology. Smart PSU optimization for gap changes. | Both are highly efficient (power factor >0.95). Ozonia’s resonance tracking adapts well to tube fouling. |

| Process Control | PLC-based (Siemens/Allen-Bradley). “Optimo” controls optimize power vs. gas flow. | “SmartO3” or equivalent. Advanced diagnostics for individual segment monitoring. | Both integrate seamlessly with SCADA via Ethernet/IP or Modbus. |

| Typical Turndown | 10% to 100% (Linear). | 10% to 100% (Linear). | Critical for matching diurnal flow patterns without wasting O2. |

| Primary Maintenance | Check fuses, cooling loop PM, PSU filter cleaning. 10-year electrode cycle. | Check fuses, cooling loop PM. Some models allow easier individual tube isolation. | Similar O&M burden. Access to tube sheets determines ease of service. |

| Application Scenario | Best Fit Attributes | Key Constraints | Recommended Technology Focus |

|---|---|---|---|

| Large Scale Municipal Drinking Water (High Flow, Continuous) | High electrical efficiency, massive capacity per vessel. | Redundancy is critical; Power quality (harmonics). | Either brand. Focus on 20-year Lifecycle Cost (LCC) and specific power (kWh/kg). |

| Wastewater Micropollutant Removal (Variable Flow) | Wide turndown ratio, fast response time. | Variable water quality; potential for high humidity environments. | Wedeco’s Effizon electrode is notably rugged for variable duty cycles. |

| Biogas Desulfurization / Sludge Lysis (Aggressive Environment) | Corrosion resistance, integration with sludge loop. | H2S presence in air; explosion proofing (Class 1 Div 2) may be required. | Requires specialized skids. Both OEMs have specific “Green” or “Eco” lines for sludge applications. Ozonia has strong history in industrial gas apps. |

| Retrofit / Space Constrained Plant | High ozone concentration (reducing gas piping size), compact footprint. | Tube pull clearance; floor loading. | Compare specific model dimensions. Ozonia often achieves higher ozone concentration (12-14wt%) allowing smaller footprints. |

Engineer & Operator Field Notes

Beyond the catalog specifications, real-world performance is determined by integration and maintenance. The following notes are derived from field experience with Xylem Wedeco vs Ozonia BioGas Equipment installations.

Commissioning & Acceptance Testing

The Factory Acceptance Test (FAT) is crucial, but the Site Acceptance Test (SAT) is where the system meets reality.

- Dew Point Verification: Ensure the feed gas dew point is strictly monitored (-60°F / -50°C or better). Moisture entering the generator reacts with nitrogen to form nitric acid, which will destroy the internal stainless steel components and dielectric fuses.

- Cooling Water Balance: During commissioning, verify flow balancing across all generators. Air pockets in the cooling jacket are a primary cause of localized hotspots and premature dielectric failure.

- Harmonic Testing: Run the VFD/PSU at various loads (30%, 50%, 100%) and measure harmonic distortion at the MCC. Ensure it meets IEEE 519 compliance.

Common Specification Mistakes

- Ignoring Ambient Conditions: Specifying standard NEMA 1 enclosures for a room that may contain traces of corrosive biogas or high humidity is a recipe for PSU failure. NEMA 12 or 4X with air conditioning is recommended for industrial/biogas areas.

- Material Mismatch: Using 304SS piping for wet ozone gas. Always use 316L SS or Schedule 80 CPVC (if pressure/temp allows, though SS is preferred for discharge).

O&M Burden & Strategy

Maintenance strategies for both Wedeco and Ozonia units share commonalities:

- Daily: Check dew point, gas pressure, and cooling water temperature.

- Monthly: Check cooling water strainers/filters. Verify safety interlocks (ambient ozone detectors).

- Annual: Inspect PSU cooling fans (critical failure point). Check dielectric fuses. Perform acid wash of cooling jackets if heat transfer efficiency drops (indicated by rising specific power consumption).

- 5-10 Year: Major overhaul. Potential dielectric replacement or seal replacement.

Troubleshooting Guide

- Symptom: High Dew Point Alarm.

Root Cause: Desiccant dryer failure or LOX evaporator leak.

Action: Immediate shutdown. Do not bypass this alarm. Moisture = Acid = Catastrophic Damage. - Symptom: Low Ozone Output vs. Power Input.

Root Cause: fouled dielectrics or high cooling water temperature.

Action: Check chiller performance first. If water temp is spec, schedule vessel inspection.

Design Details & Calculations

Sizing Logic & Methodology

To accurately compare Xylem Wedeco vs Ozonia BioGas Equipment fit, one must start with the fundamental ozone demand calculation:

$$D = Q times C_{dose} times 8.34$$

Where:

D = Ozone Demand (lbs/day)

Q = Water Flow (MGD)

Cdose = Required Dosage (mg/L)

8.34 = Conversion factor

Design Example:

For a 10 MGD plant requiring a 3 mg/L dose for disinfection:

$$D = 10 times 3 times 8.34 = 250.2 text{ lbs/day}$$

Safety Factor: Engineers typically apply a 1.25 to 1.5 safety factor for declining water quality or future flows.

Spec Requirement: 375 lbs/day capacity.

Gas Flow Calculation (SCFM):

Once the ozone mass is known, the gas flow depends on the generator concentration (typically 10-12% by weight).

$$Gas Flow (SCFM) approx frac{text{lbs/day O}_3}{Concentration (%)} times K$$

Note: Higher concentration capability (a strength of modern Ozonia and Wedeco units) results in lower gas flow, reducing the size of oxygen feed systems and contactors.

Specification Checklist

When drafting the RFP for Xylem Wedeco vs Ozonia BioGas Equipment, ensure the following are included:

- Performance Guarantee: Maximum specific power consumption (kWh/lb or kWh/kg) at 10% concentration.

- Dielectric Warranty: Minimum 5-10 year pro-rated warranty on electrode tubes.

- Harmonics: Compliance with IEEE 519 at the point of common coupling.

- Materials: 316L SS for generator vessel; PTFE/Kalrez for all wetted gaskets.

- Safety: Integration with ambient O3 and O2 monitors for automatic shutdown.

Standards & Compliance

- AWWA B304: Standard for Liquid Oxygen for Ozone Generation.

- UL 508A: Industrial Control Panels.

- ASME Section VIII: Boiler and Pressure Vessel Code (for the generator vessel).

- NFPA 820: Standard for Fire Protection in Wastewater Treatment and Collection Facilities (critical for biogas/sludge areas).

Frequently Asked Questions

What is the primary difference between Xylem Wedeco and Ozonia technologies?

The primary difference lies in the dielectric technology. Xylem Wedeco utilizes the Effizon® glass electrode, which is renowned for its mechanical robustness and resistance to thermal shock. Ozonia (Suez/Veolia) utilizes the Intelligent Gap System (IGS), often using ceramic or advanced glass/metal composites that allow for very high power densities and high ozone concentrations. Both are premium technologies, but the maintenance approach and vessel geometry differ.

How do I select the right ozone concentration for my application?

Selection depends on the contactor efficiency and feed gas source. For LOX-fed systems, running at 10-12% wt is typically the economic sweet spot, balancing oxygen costs against electrical costs. If using PSA (generated on-site), lower concentrations (6-10% wt) are often more efficient. Both Wedeco and Ozonia units can tune their output, but running at extremely high concentrations (>14%) typically increases power consumption and stress on the dielectrics.

Can these systems be used for Biogas Desulfurization?

Yes. In the context of “BioGas Equipment,” these ozone generators are used to inject small amounts of ozone into the headspace of digesters or into a specific contact loop to oxidize Hydrogen Sulfide (H2S) into elemental sulfur or sulfates. This reduces corrosion in downstream CHP engines. Special attention must be paid to materials of construction to resist the corrosive biogas environment.

What is the typical lifespan of a dielectric tube?

Under proper operating conditions (correct cooling and dew point), dielectric tubes from top-tier manufacturers like Wedeco and Ozonia should last 10-15 years. Failures are usually caused by cooling water interruptions, moisture in the feed gas (dew point > -60°F), or severe power surges. Most utilities budget for a partial or full replacement at year 15.

How does cooling water temperature affect performance?

Cooling water is critical. Ozone generation efficiency drops as temperature rises, and the rate of ozone decay increases. Standard design is usually based on 70°F (21°C) or colder water. If the plant water exceeds 85°F (30°C), a dedicated chiller is required. Operating with hot water will drastically increase power consumption and risk dielectric failure.

Are these systems compatible with SCADA for remote monitoring?

Yes. Both manufacturers provide robust PLC-based control panels (typically Allen-Bradley or Siemens) that communicate via Ethernet/IP, Profibus, or Modbus. Operators can monitor critical parameters like power factor, gas flow, cooling water temp, and ozone output remotely. N+1 redundancy logic is often handled at the master SCADA level or a master ozone control panel.

Conclusion

Key Takeaways: Comparison & Best Fit

- Efficiency is King: Evaluate based on 20-year lifecycle cost (LCC), specifically looking at kWh/kg O3 and oxygen consumption, not just capital cost.

- Dielectric Choice: Wedeco’s glass is robust and forgiving; Ozonia’s IGS allows high concentration and compact footprints. Both are proven.

- Cooling Criticality: Never value-engineer the cooling system. Closed-loop systems with proper heat exchangers are mandatory for longevity.

- Application Fit: For biogas/sludge applications, ensure the manufacturer provides corrosion-resistant skid packages compliant with NFPA 820.

- Space Planning: Account for tube-pull clearance during the design phase to avoid nightmare maintenance scenarios later.

When comparing Xylem Wedeco vs Ozonia BioGas Equipment, engineers are choosing between two high-quality, mature technologies. There is no single “winner”; the best fit depends on the specific constraints of the facility. Wedeco often shines in applications where robust, low-maintenance glass dielectrics and linear turndown are prioritized. Ozonia frequently excels in applications requiring high ozone concentrations, compact footprints, and advanced power management strategies.

For the consulting engineer, the path to a successful specification lies in defining the boundary conditions—specifically the feed gas quality, cooling water reliability, and available footprint. By focusing on the total cost of ownership and strict adherence to materials compatibility, utilities can ensure reliable oxidation performance for decades, regardless of which OEM plate ends up on the skid.