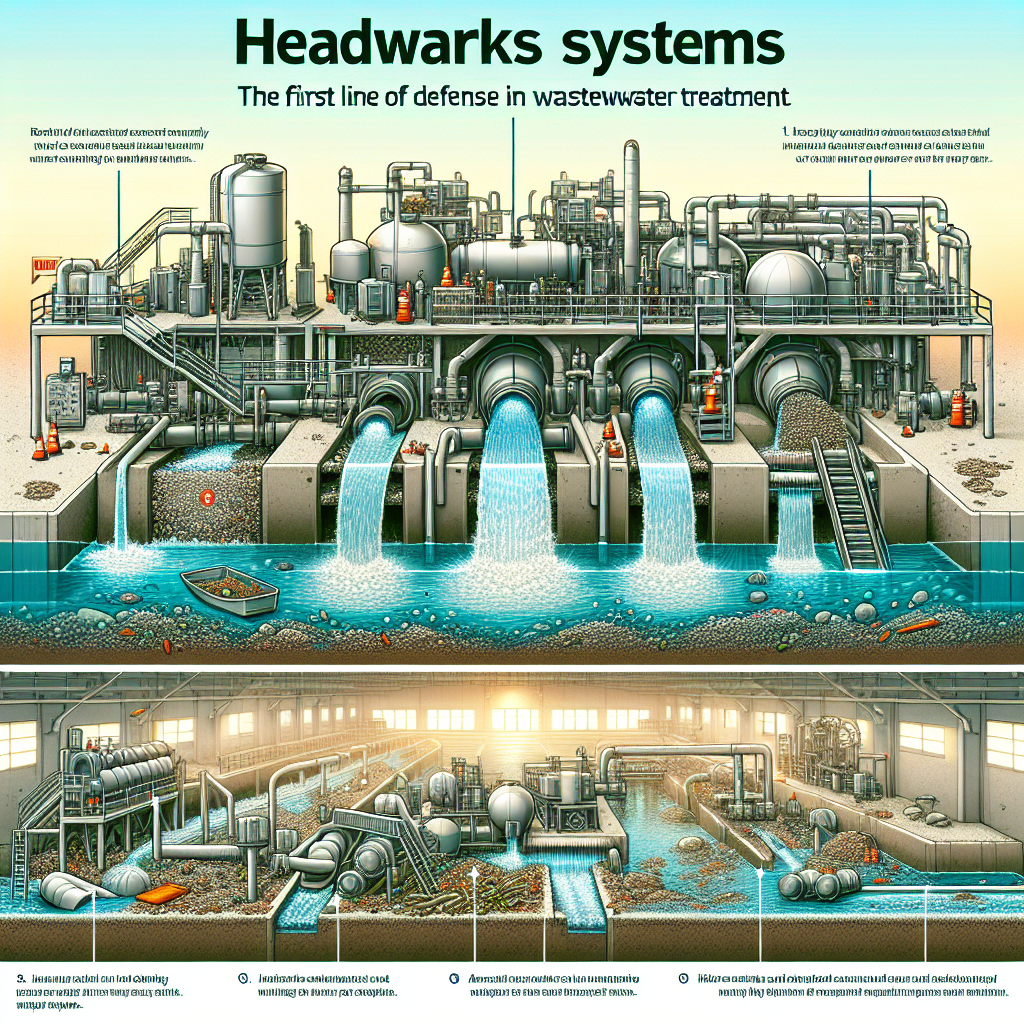

Headworks Systems: The First Line of Defense in Wastewater Treatment

Introduction

When it comes to protecting our rivers, lakes, and oceans from the unsavory mix of pollutants found in urban wastewater, the heroes of the day are often the unsung Headworks Systems. Just like a vigilant bouncer at an exclusive club, these systems stand guard at the entrance of wastewater treatment facilities, ensuring that only manageable stuff gets through while keeping out the riff-raff. But what exactly makes headworks wastewater systems so crucial?

In essence, headworks systems serve as the primary defense in wastewater management by tackling debris and grit right at the start of treatment. With an array of specialized equipment such as bar screens, grit removal systems, and influent flow controls, they ensure that large solids don’t clog or damage downstream processes. Imagine trying to enjoy a concert while someone blocks your view; that’s what debris does to equipment if not intercepted early.

- Debris Removal: Headworks equipment like mechanical screens efficiently eliminate large objects (think: tree twigs or unfortunate toys) from sewage, setting the stage for smoother operations further along.

- Grit Chambers: These tanks settle down heavy inorganic materials such as sand and gravel—those pesky particles that could otherwise wreak havoc on pipes and pumps.

- Flow Equalization: By regulating influent flows, headworks systems help maintain an even keel in downstream processes, reducing stress on both machinery and operators.

The role of headworks is not just about brute force removal; it’s also about finesse. Modern headworks facilities are increasingly automated and smartly designed to optimize performance while minimizing odors—a thoughtful nod to our olfactory senses! Innovations in bar screens for wastewater and other technologies continue to improve waste stream management at these critical entry points.

Fun Fact:

The average American produces approximately 100 gallons of wastewater per day—enough to fill over two standard bathtubs! Imagine managing this inflow without a well-designed headworks system in place!

Understanding Headworks Wastewater Systems

The headworks of a wastewater treatment plant might sound like the name of a sci-fi fortress, but in reality, it’s the crucial first line of defense in keeping our waterways clean and clear. Think of headworks as the bouncer at a club, ensuring only the right stuff gets through while keeping the riffraff (read: debris and other undesirable materials) out.

Headworks wastewater systems are designed to manage and treat all incoming sewage flows. These systems include various mechanical and hydraulic components like bar screens, grit removal chambers, and flow control devices that work harmoniously to ensure efficient primary treatment. They play an essential role in protecting downstream equipment from damage or inefficiency caused by large debris or excessive solids.

The Key Components of Headworks Systems

- Screening Equipment: Mechanical screens, ranging from coarse to fine, help remove large objects like sticks, bottles, and rags. These screens prevent blockages and protect downstream processes. Fun fact: Some facilities even use automated screening devices that can handle over 10 million gallons per day!

- Grit Removal Systems: These are your best bet for removing inorganic materials such as sand, gravel, and other heavy particles. By employing wastewater grit chambers or vortex separators, these systems prevent abrasion and wear on mechanical parts.

- Flow Control Devices: These devices manage influent flow rates, ensuring that the treatment process operates smoothly. Flow equalization tanks can be employed to balance peak flows during rainy seasons.

The strategic design of headworks systems is vital for effective wastewater management. A well-designed headworks building layout will also incorporate odor control solutions to maintain a pleasant environment for operators—because no one wants a foul-smelling fortress!

The efficiency of these systems directly impacts the overall success of sewage plants, influencing everything from sludge management to final water quality outcomes. In sum, understanding headworks is not just about technical know-how but about appreciating their unsung hero status in the world of wastewater treatment.

Key Components of Headworks Systems

When it comes to wastewater treatment, headworks systems are the unsung heroes, performing the crucial task of preparing the influent for subsequent stages. Think of these systems as a bouncer at a club, ensuring only the right kind of guests proceed to the dance floor—no riffraff allowed! Let’s delve into the key components that make up these formidable gatekeepers.

1. Screening Devices

The screening process in wastewater is akin to filtering out the biggest nuisances first. Bar screens and mechanical screens for sewage play a pivotal role in removing large debris such as sticks, leaves, and plastic materials. Bar Screens are coarse screening equipment that catches hefty solids, while finer mechanical screens tackle smaller particles. This step is crucial for preventing damage to downstream pumps and other equipment.

- Bar Screens: These are first in line and are tasked with capturing larger floating objects.

- Fine Screens: As the name suggests, they trap smaller debris not caught by their bulkier counterparts.

- Automatic Screening Devices: These modern marvels automate the debris removal process in headworks, reducing manual labor involvement.

2. Grit Removal Systems

If you’ve ever had sand in your shoes after a beach day, you’ll appreciate grit removal systems even more. These systems effectively eliminate heavy inorganic substances—like sand and gravel—from wastewater. By doing so, they prevent abrasion damage to pumps and other sensitive equipment further down the line. Wastewater grit chambers are commonly used here; they allow heavy particles to settle while lighter organic material remains suspended.

3. Flow Control Facilities

The influent flow control mechanisms ensure a constant flow rate into treatment plants, protecting them from being overwhelmed during sudden influxes (or as we like to call it: “keeping things chill”). This component is vital for maintaining operational stability across all processing stages. Flow equalization tanks often play a significant role here by storing excess water during peak flows and releasing it slowly during off-peak times.

4. Odor Control Systems

Nobody wants their neighborhood smelling like last week’s garbage stew! Odor control at headworks facilities is essential not just for nearby residents but also for plant personnel who work heroically in these environments daily. Advanced headworks odor control systems utilize various techniques such as biofilters and chemical scrubbers to keep offensive smells at bay.

Together, these key components form a robust defense line that ensures only suitably prepared waste streams proceed through subsequent primary treatment phases—making headworks systems indispensable in modern wastewater management strategies.

The Role of Headworks Equipment in Wastewater Management

When it comes to wastewater management, think of headworks equipment as the bouncers at a nightclub. They are the first line of defense, ensuring only the right “guests” make it past the velvet ropes and into the treatment process. This critical role not only sets the stage for effective downstream treatment but also protects sensitive equipment from damage.

What Does Headworks Equipment Do?

- Screening Process: One of the primary functions of headworks equipment is to perform screening processes. Bar screens for wastewater separate large debris such as sticks, rags, and other coarse solids. Think of it as an initial sweep to ensure that nothing too chunky gets through.

- Grit Removal Systems: These systems function like your morning coffee filter but with a focus on removing inorganic materials such as sand and gravel from sewage. This process helps in preventing wear and tear on plant machinery.

Mechanical Screens: As more sophisticated members of the team, mechanical screens for sewage add automation into the mix, efficiently managing influent flow control without requiring constant human oversight.

The Importance of Headworks Design

A well-designed headworks facility layout is crucial for optimal wastewater pretreatment. The design not only depends on the anticipated volume and types of waste but also considers factors like headworks odor control systems and waste stream management techniques. An intelligent layout facilitates ease of operation and maintenance while ensuring that all components work cohesively towards primary treatment in wastewater [source].

Integration with Advanced Systems

Modern headworks facilities are now incorporating hydromechanical equipment and automation solutions that enhance operational efficiency. These advanced features help in adapting to varying influent flows and optimize solids handling in wastewater treatment processes.

The importance of headworks in wastewater management cannot be overstated. By efficiently performing preliminary treatment tasks, they safeguard subsequent stages, facilitate smoother operations, and ultimately contribute to better sludge management techniques over time [source]. So next time you flush with confidence, remember the unsung heroes—headworks equipment—that make it all possible!

Design Considerations for Headworks Facilities

When it comes to headworks wastewater facilities, the design phase is where the magic happens—or at least where we hope it does! It’s not just about setting up a few screens and hoping for the best. Oh no, it’s much more nuanced than that. Here are some key considerations to keep in mind:

1. Efficient Screening Process

The screening process in wastewater treatment is crucial for removing large debris and preventing damage to downstream equipment. According to a recent discussion on bar screens, these components are fundamental in ensuring efficient solids removal. Choosing between coarse screening equipment and fine screens can significantly impact pretreatment systems’ overall efficiency.

2. Grit Removal Systems

- Importance: Grit removal systems are like your garbage disposal’s best friend, preventing sediment accumulation that could otherwise lead to blockages.

- Types: Fluidized bed grit chambers and cyclone separators each offer unique benefits suitable for different influent conditions.

3. Influent Flow Control

This isn’t just about getting things moving; it’s about getting them moving right! Flow equalization tanks help manage peak flows, ensuring headworks systems aren’t overwhelmed during high-volume periods, such as post-storm surges or Monday mornings (when all that weekend activity finally shows up).

4. Headworks Automation Solutions

The future is here, and it’s automated! Incorporating automation into headworks facilities can enhance operation efficiency, reduce human error, and optimize labor costs. Automation systems can control everything from mechanical screens for sewage to hydromechanical equipment operations.

5. Odor Control Systems

No one wants a nose full of sewage aroma wafting through the office window—trust us on this one! Installing odor control systems is essential not just for compliance but also for community relations. Activated carbon filters and biofilters are popular choices due to their effectiveness in reducing offensive smells.

Aesthetic Considerations

- Sustainability: Green roofs or living walls can be incorporated into headworks building designs to promote sustainability while improving aesthetics.

- Community Integration: Thoughtful architectural designs help facilities blend into urban environments better than a chameleon at a tie-dye festival.

The importance of thoughtful headworks design can’t be overstated; after all, it’s literally the first line of defense in your wastewater management strategy. For more insights into primary treatment processes, check out our article on the first step in pollution control.

In conclusion, whether you’re designing a new facility or upgrading an existing one, these considerations will ensure your headworks system is both efficient and effective—keeping both engineers and Mother Nature smiling!

Advanced Technologies in Headworks Systems

In the world of modern wastewater treatment, advanced technologies in headworks systems are akin to the superhero gadgets found in a sci-fi movie—minus the capes, of course. These innovations are indispensable for enhancing efficiency and ensuring that primary treatment in wastewater kicks off on the right note.

1. Automated Screening Solutions

Gone are the days when operators had to manually manage bar screens. Today, automatic screening devices for wastewater plants have transformed this cumbersome process. These devices use mechanical arms and intelligent sensors to remove debris with precision. The real hero here is their ability to operate with minimal human intervention, reducing labor costs and improving safety—because who wants to deal with smelly sludge first thing on a Monday morning?

2. Intelligent Grit Removal Systems

If you think grit is just an annoying neighbor in your teeth after a beach day, wait until you see it wreak havoc in a wastewater treatment plant! Modern grit removal systems employ vortex technology, utilizing centrifugal forces to separate sand and other inorganic materials from water efficiently. By optimizing hydrodynamic conditions, these systems contribute significantly to effective waste stream management at headworks facilities.

- Example: Vortex-type grit chambers that maximize separation while minimizing required space.

- Benefit: Improved removal efficiency reduces wear and tear on downstream equipment.

3. Advanced Odor Control Technologies

No one wants their community engulfed in the aroma of yesterday’s dinner leftovers. Headworks odor control systems have evolved significantly, employing activated carbon filters and biofilters that digest odorous compounds naturally, ensuring that nearby residents can breathe easy without holding their noses.

According to the EPA, biofilters can reduce up to 95% of hydrogen sulfide emissions from headworks facilities.

4. Automation & Monitoring Systems

The integration of automation solutions into headworks systems is nothing short of revolutionary. Through real-time data collection and remote monitoring capabilities, engineers and operators can optimize influent flow control effectively and make informed decisions on-the-fly. It’s like having a crystal ball for your plant operations—only it’s powered by IoT and AI!

- Sensors: Monitor levels of solids and alert operators about potential bottlenecks before they occur.

- User Interface: Offers intuitive dashboards for quick access to key metrics.

The implementation of these advanced technologies not only enhances the efficiency of preliminary treatment in sewage plants but also aligns with sustainable practices critical for long-term environmental stewardship.

Maintenance Practices for Optimal Performance

When it comes to keeping your headworks wastewater systems in peak condition, a little TLC goes a long way. Just like how we wouldn’t skip our car’s oil change and expect it to run smoothly (spoiler alert: it won’t), regular maintenance of headworks equipment ensures efficiency and longevity. Here’s how you can maintain your headworks systems like a pro:

1. Regular Inspections

The cornerstone of any effective maintenance plan is consistent inspections. Scheduled checks help identify wear and tear before they turn into costly breakdowns. Inspect components such as mechanical screens, grit removal systems, and bar screens to ensure they’re free from debris buildup that could impede operation.

2. Cleaning Regimens

A clean system is a happy system. Establish cleaning schedules for critical components like influent screen systems and grit chambers. Removing inorganic materials at the headworks facilities helps prevent clogging and maintains optimal flow rates.

“An ounce of prevention is worth a pound of cure.” – Benjamin Franklin

3. Lubrication

Never underestimate the power of lubrication in ensuring that your hydromechanical equipment in headworks facilities operates smoothly. Keep gears and moving parts well-oiled to reduce friction and wear, much like your morning coffee keeps you from grinding to a halt!

4. Calibration Checks

Automated systems require periodic calibration checks to ensure accuracy in influent flow control and waste stream management. For instance, automatic screening devices should be calibrated regularly to maintain optimum efficiency in debris removal.

- Daily Check: Visual inspection of screens and chambers.

- Weekly Check: Clean mechanical screens for sewage.

- Monthly Check: Lubricate moving parts.

- Semi-Annual Check: Calibrate sensors and automated equipment.

- Annual Check: Comprehensive audit for headworks facility layout optimization.

A well-maintained system not only functions better but also contributes significantly to primary treatment in wastewater processes by preventing disruptions due to mechanical failures or blockages. For more insights on efficient wastewater management practices, explore our detailed article on the importance of primary treatment in wastewater:

Primary Treatment in Wastewater: The First Step in Pollution Control.

The role of proper maintenance cannot be overstated; it’s the secret sauce that keeps your headworks building design running smoothly while ensuring environmental safety. So roll up those sleeves and get ready for some hands-on labor—your wastewater system will thank you!

Conclusion

In the intricate world of wastewater treatment, headworks systems stand as the unsung hero—the vanguard ensuring that subsequent processes run smoothly and efficiently. By serving as the first line of defense, the headworks tackle everything from grit removal to influent flow control, minimizing wear and tear on downstream equipment and optimizing operational efficiency.

The design and maintenance of the headworks facility are critical for overall plant effectiveness. A well-designed headworks system ensures that everything downstream operates within its intended parameters, protecting sewage treatment investments and enhancing environmental safety. The evolution of technologies such as automatic screening devices, hydromechanical equipment, and innovative odour control systems have revolutionized this segment, making it more robust and efficient than ever.

- Sustainability: Cutting-edge headworks designs emphasize energy efficiency, reducing carbon footprints while maintaining high performance.

- Automation: Modern systems incorporate automation to enhance accuracy in debris removal, reducing manual labor costs.

- Diverse Applications: From municipal wastewater plants to large industrial setups, headworks solutions are customizable to fit specific needs.

Moreover, as we strive for sustainable water management, integrating advanced components like fine screens and automatic grit chambers can significantly impact sludge management techniques. These improvements align with global trends emphasizing sustainability in waste stream management at headworks facilities.

If you’re interested in diving deeper into how these systems function or wish to explore more about other stages like tertiary treatment processes, feel free to explore our extensive resources on wastewater treatment solutions for enhanced environmental safety.

The innovation in headworks systems not only caters to today’s demands but also prepares us for future challenges—ensuring that we remain a step ahead in protecting our most precious resource: water.