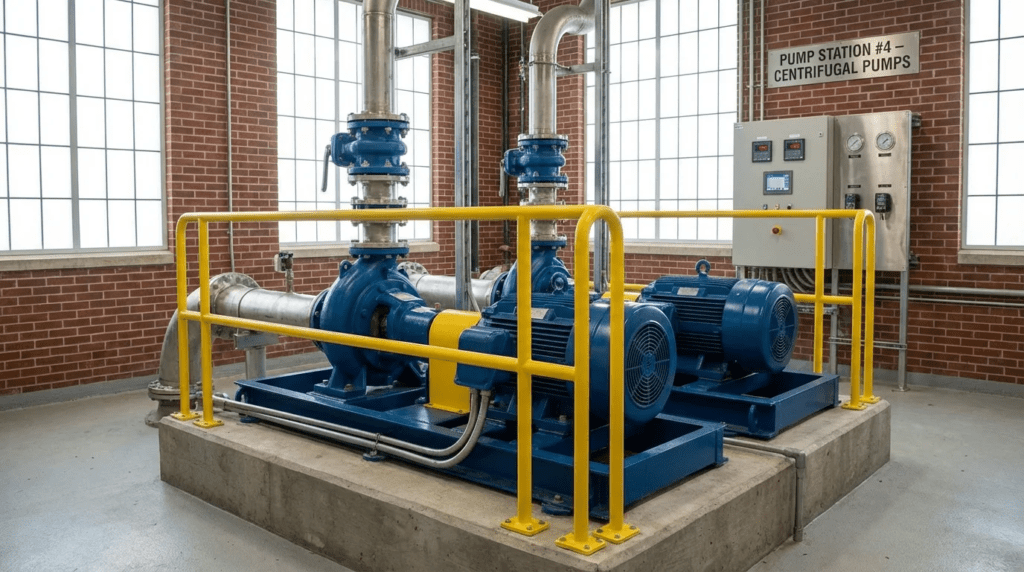

Top 10 Centrifugal Pumps Manufacturers for Water and Wastewater

Introduction

For municipal and industrial engineers, the centrifugal pump is the heartbeat of water conveyance and treatment infrastructure. However, a staggering number of pump installations fail to meet their expected lifecycle due to specification errors rather than manufacturing defects. Industry statistics suggest that over 60% of pump failures are attributed to operating outside the Preferred Operating Region (POR), poor suction piping design, or material mismatching, rather than inherent equipment flaws. The financial implication is severe: energy and maintenance costs typically account for 85-90% of a pump’s Total Cost of Ownership (TCO), dwarfing the initial capital expenditure.

This reality makes the evaluation of the Top 10 Centrifugal Pumps Manufacturers for Water and Wastewater a critical exercise in engineering due diligence. It is not merely about brand preference; it is about matching specific hydraulic technologies—such as chopper impellers, non-clog volutes, or high-efficiency split-case designs—to the unique rheology of the fluid being pumped. Whether designing a raw sewage lift station, a high-service water distribution plant, or an industrial effluent treatment system, the intersection of hydraulic efficiency and mechanical reliability is where engineering success is defined.

In the water and wastewater sector, applications range from handling potable water with low viscosity and no solids, to moving sludge with high solids content and potential ragging issues. Improper selection leads to cavitation, vibration, premature bearing failure, and catastrophic clogging. This article provides a rigorous, specification-safe analysis to help engineers navigate the market, understand the technical differentiators among leading OEMs, and specify systems that deliver long-term reliability.

How to Select and Specify Centrifugal Pumps

Selecting the right equipment from the Top 10 Centrifugal Pumps Manufacturers for Water and Wastewater requires moving beyond simple flow and head requirements. Engineers must evaluate the entire pumping system curve against the pump performance curve to ensure stability across all operating modes.

Duty Conditions & Operating Envelope

The foundation of pump specification is the accurate definition of the operating envelope. Engineers must calculate the Total Dynamic Head (TDH) at minimum, average, and peak flow rates. However, relying on a single operating point is a common pitfall.

- System Curves: Develop system curves for low (C=140/150) and high (C=100/110) friction scenarios to account for pipe aging.

- Variable Speed Operation: If using Variable Frequency Drives (VFDs), ensure the pump does not cross into unstable regions or fall below minimum scour velocities in the discharge piping at lower speeds.

- Parallel Operation: When specifying multiple pumps, analyze the combined pump curve against the system curve. Ensure that a single pump running alone does not “run out” to the far right of the curve, leading to cavitation and motor overload.

Materials & Compatibility

Water chemistry and solids composition dictate material selection. Standard cast iron volutes may suffice for neutral water, but aggressive wastewater requires robust metallurgy.

- Impellers: For wastewater containing grit, hardened chrome iron or duplex stainless steel (CD4MCu) offers superior abrasion resistance compared to standard ductile iron or bronze.

- Shafts: 400-series stainless steel is standard, but high-chloride environments (such as brackish water intake) necessitate 316L or proprietary alloys to prevent crevice corrosion.

- Wear Rings: Specify differing hardnesses between stationary and rotating wear rings (e.g., 50 Brinell difference) to prevent galling during minor operational transients.

Hydraulics & Process Performance

Balancing hydraulic efficiency with solids-passing capability is the primary challenge in wastewater pumping.

- Solids Handling: For raw sewage, specify the minimum sphere-passing diameter (typically 3 inches / 76mm). However, for fluids with high rag content, sphere size is less relevant than “self-cleaning” or semi-open impeller geometries.

- Net Positive Suction Head (NPSH): Calculate NPSH Available (NPSHa) conservatively. Require a margin of at least 1.5 to 2.0 meters (or a ratio of 1.1 to 1.3) above NPSH Required (NPSHr) to prevent cavitation, especially in suction-lift applications.

- Efficiency: While high wire-to-water efficiency is desirable, it should not compromise reliability. A vortex impeller may be less efficient than an enclosed channel impeller but offers significantly higher reliability in rag-heavy applications.

Installation Environment & Constructability

The physical constraints of the facility heavily influence manufacturer and model selection.

- Submersible vs. Dry Pit: Submersible pumps (IP68) offer flood protection and lower noise but require hoists for maintenance. Dry pit submersible pumps combine the access of dry installation with the flood resilience of a submersible motor.

- Vertical Turbine Pumps: For clean water deep wells or wet wells, ensure adequate submergence to prevent vortex formation. Verify structural stiffness to avoid resonant frequencies (Reed Critical Frequency analysis).

Reliability, Redundancy & Failure Modes

Reliability is quantified by Mean Time Between Failures (MTBF). In critical municipal applications, N+1 redundancy is the minimum standard.

- Seal Failure: Mechanical seals are the most common failure point. Specify dual mechanical seals with moisture detection sensors for wastewater applications. Cartridge seals are preferred for ease of replacement.

- Bearing Life: Specify L10 bearing life of minimum 50,000 hours, with 100,000 hours preferred for critical continuous-duty stations.

Controls & Automation Interfaces

Modern centrifugal pumps are intelligent assets. Specification must define the interface between the pump protection module and the plant SCADA.

- Monitoring: Require integral sensors for stator temperature, bearing vibration, and seal leakage.

- VFD Integration: Ensure the motor insulation is Class H or F with VFD-rated wiring (inverter duty) to withstand voltage spikes (dV/dt).

Maintainability, Safety & Access

Design for the operator who must service the equipment at 2:00 AM.

- Access: For self-priming pumps, ensure the back-pull-out assembly or inspection cover is accessible without removing discharge piping.

- Lifting: Specify permanent lifting eyes or davit cranes rated for the specific weight of the heaviest maintainable component.

Lifecycle Cost Drivers

Engineers must perform a Lifecycle Cost Analysis (LCCA) that includes:

- Energy Consumption: Based on the weighted average of operating points, not just the Best Efficiency Point (BEP).

- Maintenance Labor: Estimate hours for seal changes and clearance adjustments.

- Parts Availability: Consider the manufacturer’s local support network and lead times for critical spares like impellers and motors.

Manufacturer and Technology Comparison

The following tables provide an objective engineering comparison of leading manufacturers and pump technologies. Table 1 outlines the strengths and typical applications of the Top 10 Centrifugal Pumps Manufacturers for Water and Wastewater. Table 2 provides a matrix for selecting the correct pump architecture based on application constraints. These comparisons are based on general industry capabilities and standard product lines.

| Manufacturer | Primary Technical Strengths | Typical Applications | Engineering Considerations | Maintenance Profile |

|---|---|---|---|---|

| Xylem (Flygt) | Self-cleaning “N-Technology” impellers; Integrated intelligence (Concertor); Submersible motor design. | Raw wastewater lift stations; Stormwater retention; RAS/WAS pumping. | Proprietary mounting systems (guide rails); High initial capital cost for intelligent units. | Moderate; requires specialized tools for some proprietary seals. |

| Grundfos | High-efficiency vertical multistage (CR series); Digital dosing; Smart motor controls (MGE). | Water boosting; Dosing/Disinfection; Tertiary treatment; Groundwater supply. | Less dominant in large-solids raw sewage compared to others; focus is often on clean water efficiency. | Low; cartridge seals allow fast changes; widely available parts. |

| KSB | Heavy-duty industrial construction; Large axial flow pumps; Amarex series wastewater pumps. | Large municipal intake; Flood control; Industrial wastewater; Slurry transport. | Lead times can be longer for custom heavy-duty units; excellent hydraulic efficiency. | Robust; designed for long intervals between overhauls. |

| Sulzer | Clog-resistance (Contrablock); High-speed turbocompressors (adjacent); Submersible mixers. | Headworks; Screening channels; Anoxic zones; Abrasive sludge. | Verify hydraulic coverage for very low flow/high head applications. | Standard mechanical maintenance; adjustable wear plates on some models. |

| Flowserve | Massive scale infrastructure; Vertical turbine; Split-case double suction. | Raw water intake; Desalination; Large distribution networks. | Generally over-engineered for small package lift stations; best for custom, large-scale specs. | High expertise required; typically requires crane access and site machining. |

| Gorman-Rupp | Self-priming centrifugal technology; Above-ground maintenance philosophy. | Lift stations with suction lift requirements; Package systems; Bypass pumping. | Limited by NPSHa and suction lift physics (approx. 25 ft max); footprint larger than submersibles. | Excellent; operator-friendly access plates allow clearing clogs without tools. |

| Wilo | ECM motor technology; Ceram coatings; Solid separation systems. | Commercial buildings; Municipal water supply; Sewage collection. | Stronger presence in Europe/Asia; verify local support network in specific North American regions. | Low; focus on maintenance-free motor designs. |

| Ebara | Stamped stainless steel manufacturing; Submersible grinder pumps. | Drainage; Sump applications; Small to medium wastewater transfer. | Lighter duty construction on small models compared to cast iron heavyweights; excellent corrosion resistance. | Disposable mentality for smaller units; standard repair for larger range. |

| Pentair (Fairbanks Nijhuis) | Solids handling; Chopper pumps; Vortex hydraulics; Bi-directional flow pumps. | Tough solids applications; Flood protection; Fire water systems. | Wide variety of brands under umbrella can complicate specification consistency. | Standard; chopper components require periodic sharpening/adjustment. |

| Cornell Pump | Cutter pumps; Run-Dry capability (Cycloseal); High head waste pumps. | Agricultural waste; Municipal digesters; Mining/Dewatering. | Niche focus on challenging hydraulics; fewer options for standard vertical multistage clean water. | Specialized; seal system is unique and highly reliable if maintained correctly. |

| Scenario | Recommended Technology | Critical Constraints | Operator Skill Impact | Relative Cost (CAPEX) |

|---|---|---|---|---|

| Raw Sewage Lift Station (Deep) | Submersible Non-Clog (Dry or Wet Pit) | Clogging (Rags/Wipes); H2S Corrosion | Low (if monitoring is automated) | Medium |

| Raw Sewage (Suction Lift <20ft) | Self-Priming Centrifugal | NPSH Available; Priming time | Medium (Clearances/Belts) | Medium-High |

| Clean Water Distribution | Horizontal Split-Case or Vertical Turbine | Efficiency; Seal maintenance | Medium (Alignment/Greasing) | High |

| Sludge / Digester Recirculation | Chopper or Screw Centrifugal | Viscosity; Abrasiveness; Hard Solids | High (Cutting tolerances) | High |

| High Pressure Booster | Vertical Multistage | Inlet pressure; Deadhead protection | Low (Cartridge seals) | Low-Medium |

Engineer and Operator Field Notes

Successful pumping systems rely on more than just the datasheet. The following insights bridge the gap between design theory and operational reality when dealing with the Top 10 Centrifugal Pumps Manufacturers for Water and Wastewater.

Commissioning & Acceptance Testing

The Site Acceptance Test (SAT) is the final gatekeeper before ownership transfer. Do not rely solely on the Factory Acceptance Test (FAT).

- Vibration Baseline: Establish a vibration baseline across the full operating range (minimum to maximum Hz). Use ISO 10816-7 (Pumps) standards. High vibration at low speeds often indicates resonance or critical speed issues in VFD applications.

- Hydraulic Verification: Verify the duty point by measuring suction and discharge pressure gauges simultaneously with flow metering. Calibrate gauges before testing; a 2 psi error can significantly skew head calculations.

- Amp Draw: Compare amperage readings on all three phases. Imbalance greater than 5% indicates power quality issues or winding defects.

Common Specification Mistakes

Analysis of failed projects often reveals recurring errors in the Request for Proposal (RFP) or bid documents.

- Oversizing: Engineers often apply excessive safety factors, resulting in a pump that operates far to the left of the Best Efficiency Point (BEP). This causes high radial loads, shaft deflection, and premature seal failure. Aim for operation between 80% and 110% of BEP.

- Ignoring Net Positive Suction Head (NPSH): Assuming sea level atmospheric pressure at higher elevations is a fatal error. Always correct for altitude and water temperature (vapor pressure) when calculating NPSHa.

- Vague Material Specs: Specifying “Stainless Steel” is insufficient. Specify grades (e.g., 316, 317L, CD4MCu, 2205 Duplex) based on chloride content and pH levels.

O&M Burden & Strategy

Operational strategies must align with the specific pump type selected.

- Impeller Clearance: For semi-open impellers and chopper pumps, hydraulic performance degrades as the gap between the impeller and wear plate increases. Schedule clearance adjustments every 6-12 months to restore efficiency and cutting capability.

- Seal Water Systems: If using external flush seals, the seal water system requires as much maintenance as the pump itself. Ensure flow indicators are functional and filters are clean.

- Lubrication: Avoid mixing grease types. Polyurea and Lithium-based greases are generally incompatible and can harden, causing bearing failure.

Troubleshooting Guide

Symptom: No Flow or Low Flow

- Air lock in the volute (common in sewage pumps after maintenance).

- Incorrect rotation direction.

- Clogged suction line or impeller.

- Excessive wear ring clearance.

Symptom: Excessive Noise/Vibration

- Cavitation (Gravel sound): NPSHa is lower than NPSHr. Check for suction blockage or high temperature.

- Recirculation (Crackling sound): Pump is operating too far back on the curve (low flow).

- Mechanical: Misalignment, bent shaft, or unbalance.

Design Details and Calculations

Rigorous calculation is the antidote to operational surprises. When selecting from the Top 10 Centrifugal Pumps Manufacturers for Water and Wastewater, applying consistent sizing logic is mandatory.

Sizing Logic & Methodology

The Total Dynamic Head (TDH) calculation must be precise. The formula is:

TDH = hs + hf + hv + hp

- hs (Static Head): The vertical distance from the suction water level to the discharge water level. Note: This changes as wet well levels fluctuate.

- hf (Friction Head): Energy loss due to pipe friction and fittings. Use the Hazen-Williams equation for water/wastewater.

Equation: hf = 10.44 * L * Q1.85 / (C1.85 * d4.87) - hv (Velocity Head): V2/2g. Often negligible in high-head systems but critical in low-head, high-flow applications.

- hp (Pressure Head): The pressure required at the discharge point (e.g., to feed a pressurized force main).

Specification Checklist

Ensure your specification document includes the following specific requirements:

- Performance Testing: Require testing to Hydraulic Institute (HI) 11.6 or 14.6 standards. Specify Grade 1U or 1B tolerances if efficiency is critical.

- Coating Systems: For wastewater, specify ceramic epoxy or fusion-bonded epoxy for the volute interior to resist abrasion and corrosion.

- Motor Service Factor: Specify a 1.15 service factor, but size the motor to operate without using the service factor at the end of the curve (run-out).

Standards & Compliance

Adherence to industry standards ensures safety and interoperability.

- AWWA E103: Standard for Horizontal and Vertical Line-Shaft Pumps.

- ANSI/HI 9.6.1: Guideline for NPSH margin.

- ANSI/HI 9.6.3: Guideline for Allowable Operating Region (AOR) and Preferred Operating Region (POR).

- NFPA 820: Standard for Fire Protection in Wastewater Treatment and Collection Facilities (dictates explosion-proof motor requirements).

Frequently Asked Questions

What defines the “Top 10 Centrifugal Pumps Manufacturers for Water and Wastewater”?

The “Top 10” are generally defined by their global installed base, breadth of product portfolio, compliance with ANSI/HI standards, and ability to support municipal and industrial scale projects. Companies like Xylem, Grundfos, KSB, and Flowserve consistently appear in major engineering specifications due to their proven reliability, parts availability, and advanced hydraulic designs (such as non-clog or chopper impellers) specifically engineered for water and wastewater challenges.

How do I determine the Best Efficiency Point (BEP) for a centrifugal pump?

The BEP is the flow rate at which the pump operates at maximum hydraulic efficiency for a given impeller diameter and speed. It is located at the peak of the efficiency curve provided by the manufacturer. Engineers should size the pump so that the primary duty point falls within 80% to 110% of the BEP. Operating significantly outside this range increases radial loads, vibration, and cavitation risk.

What is the difference between static head and dynamic head?

Static head is the vertical distance the water must be lifted (from source surface to discharge point) and is constant regardless of flow rate (unless tank levels change). Dynamic head (or friction head) is the energy required to overcome friction in pipes and fittings, which increases exponentially with flow. Total Dynamic Head (TDH) is the sum of both. Understanding this distinction is crucial for system curve development.

Why is NPSH margin important in pump selection?

NPSH (Net Positive Suction Head) margin is the safety buffer between the energy available in the fluid (NPSHa) and the energy required by the pump to prevent cavitation (NPSHr). A margin of at least 1.5 to 2.0 meters (5-7 feet) is recommended. Without this margin, localized pressure drops inside the impeller can cause fluid to vaporize and collapse (cavitation), causing severe pitting damage and noise.

When should I specify a chopper pump versus a standard non-clog pump?

Specify a chopper pump when the waste stream contains long fibers, rags, wipes, or tough solids that typically bind standard impellers. Chopper pumps use sharpened blades to condition solids into a slurry. Standard non-clog pumps rely on large sphere-passing capability (vortex or channel impellers). If “ragging” is a frequent maintenance issue, a chopper pump or a macerating stage is often the best solution despite slightly lower hydraulic efficiency.

How does a VFD impact centrifugal pump selection?

A Variable Frequency Drive (VFD) allows a pump to operate across a range of flows, matching output to demand. However, when selecting a pump for VFD use, engineers must ensure the pump does not operate below the minimum flow required for cooling or solids suspension (scour velocity) in the pipe. Additionally, the motor must be “inverter duty” rated to withstand the electrical stress caused by the drive.

Conclusion

KEY TAKEAWAYS

- Define the Fluid: Analyze solids content, pH, and temperature before selecting materials. Ductile iron is standard; Duplex Stainless is for corrosion/abrasion.

- Calculate, Don’t Guess: Establish accurate system curves for minimum and maximum friction scenarios. Calculate NPSHa for the worst-case suction condition.

- Respect the Curve: Select pumps to operate within the Preferred Operating Region (80-110% of BEP). Avoid the “danger zones” of recirculation and run-out.

- Total Cost of Ownership: Energy and maintenance account for ~90% of lifecycle costs. A 5% efficiency gain or a non-clog design often justifies a higher initial purchase price.

- Standardization: Selecting from the Top 10 Centrifugal Pumps Manufacturers ensures access to spare parts, service data, and standardized flange dimensions.

- Verify Installation: Proper grouting, alignment, and piping design (straight run into suction) are as critical as the pump hardware itself.

Selecting equipment from the Top 10 Centrifugal Pumps Manufacturers for Water and Wastewater is a multifaceted engineering challenge that balances hydraulics, mechanical integrity, and operational reality. There is no single “best” manufacturer; rather, there is a “best fit” for every specific application. A heavy-duty slurry pump from one OEM may be ideal for a grit chamber, while a high-efficiency vertical turbine from another is superior for finished water distribution.

Engineers and operators must collaborate to define the true constraints of the system. By prioritizing the operating envelope, ensuring material compatibility, and designing for maintainability, utilities can secure assets that provide decades of reliable service. The goal is to move beyond the initial specification and focus on the 20-year operational horizon, where the true value of engineering rigor is realized.