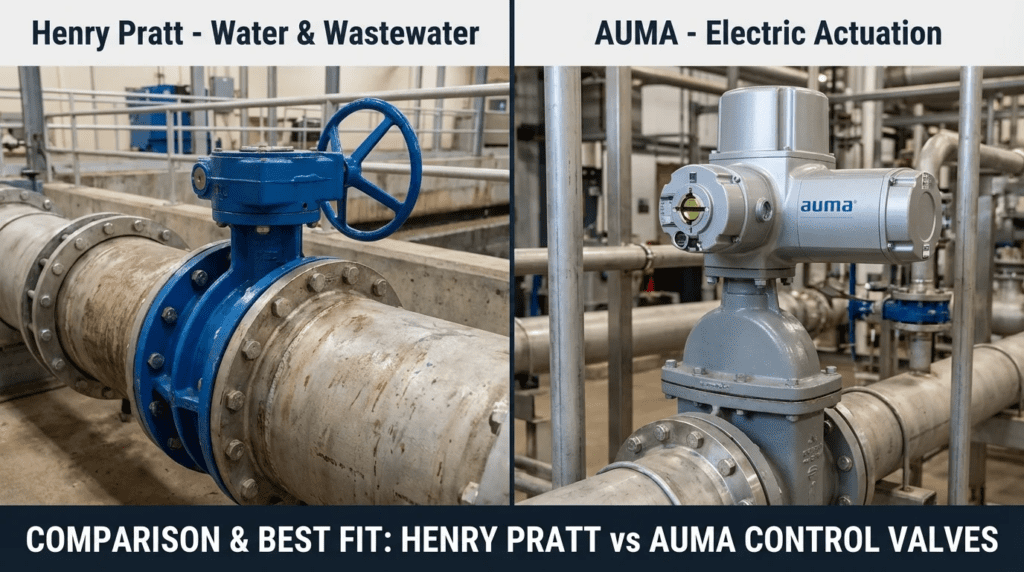

Henry Pratt vs AUMA Control Valves Equipment: Comparison & Best Fit

Introduction

One of the most persistent challenges in municipal water and wastewater design is the “interface gap”—the point where mechanical flow control meets electrical automation. When a critical isolation valve fails to close during a storm event, or a modulating control valve oscillates wildly, creating damaging water hammer, the root cause often lies in a mismatch between the valve body and the actuation unit. Engineers frequently face a specification dilemma: Should they specify a “single-source” package from a valve manufacturer, or should they decouple the specification to pair best-in-class mechanics with best-in-class electronics?

This brings us to the critical analysis of Henry Pratt vs AUMA Control Valves Equipment: Comparison & Best Fit. While Henry Pratt is a dominant force in North American fluid control (specifically large-diameter butterfly and plug valves), AUMA is a global leader in modular electric actuation. The comparison is rarely “Valve A vs. Valve B,” but rather a strategic decision between “Pratt’s Integrated Package” (Pratt valve + Pratt/OEM actuator) versus a “Component Specification” (Pratt valve + AUMA actuator).

This distinction is vital. In municipal treatment plants, raw water intakes, and distribution pump stations, the consequences of poor selection include premature motor burnout, stripped stems, and the inability to integrate with modern SCADA systems via protocols like Ethernet/IP or PROFIBUS. This article provides consulting engineers and utility directors with the technical framework to determine the Henry Pratt vs AUMA Control Valves Equipment: Comparison & Best Fit for their specific hydraulic and operational constraints.

How to Select / Specify

Selecting the correct control valve assembly requires analyzing the mechanical valve requirements alongside the automation capabilities. The engineering goal is to ensure the actuator can deliver the required torque across the full range of the valve’s lifecycle while providing the necessary data to the control system.

Duty Conditions & Operating Envelope

The first step in determining the fit is defining the duty cycle. Large AWWA C504 butterfly valves used for isolation typically operate infrequently (Open/Close service). In this scenario, a standard Pratt MDT (traveling nut) manual operator or a basic electric motor operator is often sufficient. However, if the application involves flow pacing or pressure control, the equipment enters “modulating duty.

Modulation classes (EN 15714-2) must be defined:

- Class A/B (On-Off/Inching): Standard isolation. Pratt’s standard bundled actuation is typically cost-effective here.

- Class C (Modulating): Requires up to 1,200 starts per hour. This is where AUMA’s specific modulating duty actuators (SAR range) often outperform standard OEM packages, managing heat dissipation and mechanical wear more effectively.

- Class D (Continuous Modulation): High-performance control. AUMA actuators designed for this duty eliminate the “hunting” often seen in less sophisticated gear trains.

Materials & Compatibility

While Henry Pratt valves are renowned for their robust cast iron and ductile iron construction (meeting ASTM A126/A536), the actuator housing material is equally critical. In wastewater headworks or corrosive chemical feed rooms, aluminum actuator housings can suffer rapid degradation. When comparing Henry Pratt vs AUMA Control Valves Equipment: Comparison & Best Fit, engineers must evaluate the coating systems.

AUMA typically offers a double-sealed enclosure design where the terminal compartment is separate from the internal electronics, protecting the unit from moisture ingress during wiring—a common failure point in humid pipe galleries. Pratt’s mechanical gearboxes are heavy-duty but rely on external limit switches and positioners when automated with third-party hydraulics or basic motors, creating more potential ingress points.

Hydraulics & Process Performance

The valve’s Cv (flow coefficient) curve dictates the actuator’s required speed and precision. A butterfly valve has a non-linear flow characteristic. To achieve linear flow control, the actuator must be capable of multi-point characterization (mapping the input signal to a non-linear output position). AUMA’s integral controls (AC .2) allow for customizable characteristic curves directly at the device level, correcting the valve’s hydraulic non-linearity without burdening the PLC logic.

Installation Environment & Constructability

Space in valve vaults is premium real estate. Pratt butterfly valves are compact (short laying length), but the actuation assembly can be bulky.

- Orientation: Can the actuator be mounted in any orientation? AUMA actuators generally support 360-degree mounting, but oil-filled gearboxes from legacy lines may have specific orientation limits to ensure lubrication of the worm gear.

- Cabling: Decoupled systems (Valve + separate Actuator) may require more complex field coordination regarding mounting brackets and stem couplings compared to a factory-assembled Pratt package.

Reliability, Redundancy & Failure Modes

Reliability analysis focuses on the “Loss of Signal” and “Loss of Power” behavior.

Safe Failure: Does the valve need to fail open, fail closed, or fail in last position?

Pratt Hydraulic Systems: Often superior for “Fail Safe” applications requiring rapid closure (using accumulators or spring returns) without electric power.

AUMA Electric: Requires a battery backup module (FQM) or supercapacitors to drive to a safe position upon power loss, which adds complexity but offers better diagnostics than hydraulics.

Controls & Automation Interfaces

This is the primary differentiator in the Henry Pratt vs AUMA Control Valves Equipment: Comparison & Best Fit analysis. AUMA excels in high-level data integration.

- Data Density: AUMA actuators can transmit torque profiles, motor temperature, vibration data, and stroke counts via fieldbus.

- Pratt Standard: Often utilizes standard dry contacts (Limit Open/Close, Torque Trip) unless a high-spec actuator is requested.

Lifecycle Cost Drivers

CAPEX: A Pratt valve with a standard commercial actuator is almost always cheaper initially than a Pratt valve with a specified AUMA actuator.

OPEX: AUMA units reduce OPEX through non-intrusive setting (no opening covers to set limits) and predictive maintenance data (warning of tight valves before they stall). Standard actuators may require manual limit switch adjustment which involves lockout/tagout and opening the enclosure.

Detailed Comparison Data

The following tables provide a structured comparison to assist engineers in specification. Table 1 focuses on the technological differences between a standard Pratt OEM actuation package and a specified AUMA solution. Table 2 provides an application matrix to identify the best fit for specific plant areas.

Table 1: Technology & Feature Comparison

| Feature / Attribute | Henry Pratt (Standard OEM/Integrated Pkg) | AUMA (Specified Actuation) | Engineering Implication |

|---|---|---|---|

| Primary Focus | Valve Mechanics & Fluid Control | Automation, Intelligence & Motor Control | Pratt is the expert in the seal; AUMA is the expert in the movement. |

| Actuation Technology | Hydraulic cylinders, MDT manual gears, basic electric (varies by sub-vendor). | Modular Electric (Multi-turn, Part-turn, Linear) with integral controls. | Use Pratt Hydraulic for high-speed emergency closure; use AUMA for precision control. |

| Commissioning Method | Often intrusive (remove cover to set mechanical cams/switches). | Non-intrusive (Bluetooth or magnetic wand via glass). | Non-intrusive is safer in wet/hazardous environments and faster to commission. |

| Diagnostics | Basic (Open/Close/Overload). | Advanced (Torque curves, vibration, starts/hour, temperature). | Advanced diagnostics support predictive maintenance (PdM) programs. |

| Mounting Standard | Proprietary or AWWA C504/C542. | ISO 5211 (Global Standard). | ISO 5211 facilitates easier future retrofits of the actuator. |

| Corrosion Protection | Epoxy / Paint (standard industrial). | Powder coating with double-sealed enclosure (KN/KS variants). | AUMA generally preferred for highly corrosive atmospheres (H2S environments). |

Table 2: Application Fit Matrix

| Application Scenario | Best Fit Strategy | Key Decision Factor |

|---|---|---|

| Buried Service Isolation | Pratt MDT (Manual) | No electricity required; extremely rugged; submersible; zero maintenance. |

| Raw Water Intake (High Torque/Debris) | Pratt Valve + AUMA Actuator | AUMA’s “torque retry” logic can attempt to clear obstructions; high torque capability handles debris loads. |

| Filter Effluent Control (Modulating) | Pratt Valve + AUMA SAR (Modulating) | Requires high precision (Class C/D) to maintain level/flow; prevents hunting and gear wear. |

| Emergency Pump Check (Rapid Close) | Pratt Hydraulic System | Electric actuators are generally too slow for surge prevention; hydraulics provide stored energy closure. |

| Remote Lift Station (SCADA Integrated) | Pratt Valve + AUMA w/ Profibus/Ethernet | Minimizes I/O wiring; allows remote monitoring of valve health where operators rarely visit. |

Engineer & Operator Field Notes

Field experience often differs from catalog specifications. The following notes are compiled from commissioning logs and long-term maintenance records regarding the Henry Pratt vs AUMA Control Valves Equipment: Comparison & Best Fit.

Commissioning & Acceptance Testing

The “Seating” Controversy: A common dispute during commissioning is whether to set the valve limits based on “Position” or “Torque.”

- Pratt Butterfly Valves: Generally seat on position. The rubber seat interferes with the disc edge to create the seal. Driving on torque can over-compress and damage the seat.

- AUMA Default: High-end actuators often default to torque seating for wedge gate valves. Engineers must verify the AUMA logic is set to “Limit Seating” for butterfly valves during the FAT/SAT to prevent seat damage.

Common Specification Mistakes

One of the most frequent errors in specifications is the “Master/Slave” relationship confusion.

Mistake: Specifying the actuator torque exactly at the valve’s unseating torque requirement.

Reality: Valves that sit closed for months (calcification/stiction) require significantly higher “break-to-open” torque.

Correction: Always apply a safety factor (typically 1.5x) to the valve manufacturer’s torque requirement when sizing the AUMA actuator. Ensure the valve shaft’s MAST (Maximum Allowable Stem Torque) exceeds the actuator’s stall torque, or stem twisting will occur during a jam.

O&M Burden & Strategy

Operators prefer consistency. If a plant is 80% AUMA, introducing a different actuator brand via a Pratt package creates training gaps.

Maintenance Interval:

- Pratt MDT Gears: Grease packed. Often “lubed for life” for buried service, or annual inspection for vaults.

- AUMA Actuators: Oil bath lubrication. Check oil levels annually; replace seals every 5-7 years depending on environment. Battery replacements for display units are a recurrent maintenance item (typically every 5 years).

Troubleshooting Guide

Symptom: Actuator trips on torque in mid-travel.

Potential Cause: This is rarely a valve body issue unless there is major debris. More often, it is a tight packing gland or a bent shaft.

Diagnostic: AUMA actuators can display a “Torque Profile.” If the torque spikes at a specific degree of rotation, it indicates mechanical interference. If torque is high throughout, it suggests overtightened packing or bearing seizure.

Design Details: Sizing & Interfaces

Sizing Logic & Methodology

To ensure a successful integration in the Henry Pratt vs AUMA Control Valves Equipment: Comparison & Best Fit, the following calculation path is recommended:

- Determine Hydrodynamic Torque (T_dyn): $T_{dyn} = C_t times D^3 times Delta P$. (Where $C_t$ is the torque coefficient provided by Pratt).

- Determine Seating/Unseating Torque (T_seat): This is friction-dominated and highest at closure.

- Apply Safety Factor (SF): $T_{req} = max(T_{dyn}, T_{seat}) times 1.5$.

- Select Actuator: Choose an AUMA model where Rated Torque > $T_{req}$.

- Check MAST: Verify that Actuator Max Torque < Valve Shaft MAST. If Actuator Torque > MAST, you risk shearing the shaft if the valve jams. If this condition exists, a torque limiter must be programmed into the actuator control logic.

Standards & Compliance

AWWA C504 (Rubber-Seated Butterfly Valves): Defines the proof of design tests for the valve.

AWWA C542 (Electric Motor Actuators): The governing standard for the actuator.

NEMA / IP Ratings: For wastewater applications, specify NEMA 6 (IP68) submersible rating for 72 hours at 20 feet minimum. Vaults flood; standard NEMA 4X (rainproof) is insufficient for below-grade piping galleries.

Frequently Asked Questions

Why separate the valve and actuator specification?

Decoupling the specification allows the engineer to standardize the “brain” (actuator) across the plant while selecting the best “muscle” (valve) for each specific fluid application. While Henry Pratt provides excellent valves, a plant may want AUMA actuators everywhere to simplify SCADA integration, spare parts inventory, and operator training, regardless of who makes the valve body.

What is the difference between Henry Pratt’s MDT and AUMA’s Gearbox?

Henry Pratt’s MDT (Traveling Nut) manual operator is a proprietary design optimized for their butterfly valves, offering high mechanical advantage and self-locking characteristics essential for preventing water hammer. AUMA’s worm gearboxes are general-purpose multi-turn to quarter-turn reducers. While both work, the Pratt MDT is specifically engineered to match the torque curve of Pratt valves.

Can AUMA actuators be retrofitted onto old Pratt valves?

Yes, this is a common upgrade. However, it requires an adaptation bracket and a stem coupling. Old Pratt valves often have keyed shafts or square nuts. Accurate field measurements of the “top works” (mounting flange and stem dimensions) are critical. You must also verify the valve is still mechanically sound; automating a seized valve will only result in broken equipment.

How does the cost compare between a bundled package and a custom AUMA spec?

Specifying a Henry Pratt valve with a requested AUMA actuator typically costs 15-25% more than the standard Pratt package (valve + commercial actuator). This premium covers the hardware cost difference, the separate procurement logistics, and the custom mounting fabrication. However, the lifecycle cost may be lower due to standardized maintenance and superior diagnostics.

Does Henry Pratt manufacture their own electric actuators?

Henry Pratt offers branded actuation solutions, but they historically partner with actuator OEMs or use industrial-grade commercial actuators for their standard electric packages. They also manufacture heavy-duty hydraulic actuation systems. AUMA, conversely, is a dedicated actuator manufacturer. Understanding this core competency is key to the Henry Pratt vs AUMA Control Valves Equipment: Comparison & Best Fit.

What is the best choice for checking water hammer?

For pump check service where water hammer is a concern, standard electric actuation (AUMA or otherwise) may be too slow. Henry Pratt’s hydraulic control systems with accumulators are often the “Best Fit” here, as they can provide adjustable two-speed closing profiles to dampen surge energy effectively, independent of the power grid.

Conclusion

Key Takeaways

- Define Responsibility: Choose between Single Source Responsibility (Pratt Pkg) for simplicity or Component Specification (Pratt + AUMA) for performance standardization.

- Check the Duty: For standard isolation, Pratt’s native setup is sufficient. For modulation (Class C/D), AUMA is superior.

- Safety Factors: Ensure Actuator Torque < Valve Shaft MAST to prevent mechanical failure.

- Environment: Specify NEMA 6/IP68 for all vault-installed equipment.

- Integration: If your SCADA relies on PROFIBUS/Ethernet, AUMA offers deeper data integration than standard mechanical setups.

In the final analysis of Henry Pratt vs AUMA Control Valves Equipment: Comparison & Best Fit, the “winner” depends entirely on the application criticality and the plant’s operational philosophy.

For decentralized, manually operated, or simple open/close isolation valves in distribution systems, Henry Pratt’s integrated manual or basic electric packages offer rugged reliability and single-source warranty simplicity. They are the cost-effective, “install and forget” solution.

However, for critical process control, filter galleries, and highly automated treatment facilities, pairing the robust mechanics of a Henry Pratt butterfly or plug valve with the intelligence of an AUMA multi-turn or part-turn actuator is often the optimal engineering choice. This hybrid approach provides the mechanical longevity required for water service with the diagnostic granularity required for modern asset management.

Engineers should move away from generic “or equal” specifications and instead explicitly define the actuator performance criteria—duty cycle, enclosure rating, and data protocols—to ensure the selected equipment meets the 20-year lifecycle demands of municipal infrastructure.