Top OEMs for Pneumatic Valve Actuators

Introduction

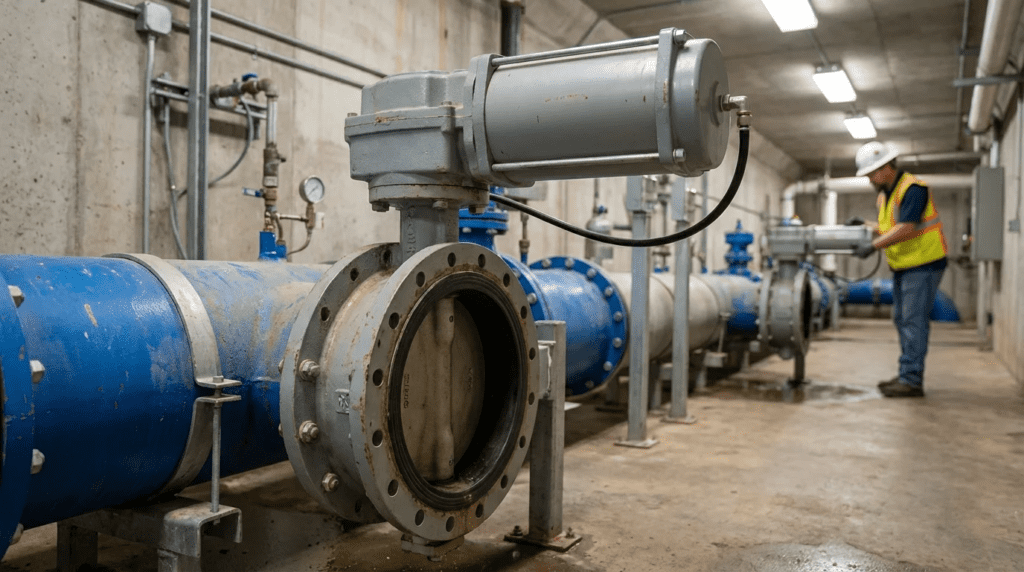

In the complex infrastructure of municipal water and wastewater treatment, the actuation of valves is the muscle behind process control. While electric actuation has gained ground due to advances in network connectivity, pneumatic valve actuators remain a cornerstone of industry reliability, particularly in applications requiring rapid response, high duty cycles, and fail-safe operation. For municipal consulting engineers, plant managers, and utility superintendents, understanding the engineering nuances of pneumatic actuation is critical for specifying systems that minimize downtime and lifecycle costs.

Pneumatic actuators utilize compressed air—typically “instrument air” dried and filtered to specific standards—to convert energy into mechanical motion. This motion controls the position of final control elements such as butterfly valves, ball valves, plug valves, and gate valves. In a Water Treatment Plant (WTP) or Wastewater Treatment Plant (WWTP), pneumatic actuators are ubiquitous. They are the standard for filter backwash sequences due to their speed and ability to handle high cycle counts without overheating. They are essential in aeration basin control, chemical feed modulation, and digester gas isolation systems.

The regulatory context for these devices involves strict adherence to safety and environmental standards. In wastewater headworks or anaerobic digesters, actuators must often meet explosion-proof ratings (Class I, Div 1 or 2). In drinking water applications, while the actuator itself does not touch the media, its lubricants and external coatings must be compatible with washdown environments and potential incidental contact. Furthermore, the push for energy efficiency in municipalities places scrutiny on the air generation system; leaky or inefficient actuators contribute to phantom loads on plant air compressors.

Selecting the Original Equipment Manufacturer (OEM) for pneumatic actuators is not merely a purchasing decision; it is a long-term engineering commitment. The compatibility of the actuator with the valve, the availability of seal kits ten years post-installation, and the resistance of the housing to corrosive hydrogen sulfide (H2S) atmospheres are all determined by the OEM’s manufacturing philosophy. This article provides a technical, specification-safe analysis of the leading OEMs in the pneumatic actuator market, tailored specifically for the water and wastewater sector.

How to Select Pneumatic Valve Actuators

Selecting the correct pneumatic actuator requires a holistic view of the process conditions, the valve torque profile, and the available instrument air infrastructure. Engineers must move beyond simple sizing charts and consider the physics of the application to ensure operational longevity.

1. Mechanism Design and Torque Profile

The internal mechanism of the actuator dictates its torque output curve, which must be matched to the valve’s torque requirement.

- Rack and Pinion: This is the most common design for quarter-turn valves (butterfly, ball, plug). It offers a linear torque output throughout the stroke. It is compact, cost-effective, and reliable for general isolation and modulation duties. However, because valve torque is typically highest at “break” (opening) and “reseat” (closing), a rack and pinion actuator must be sized for the peak torque, often resulting in excess torque during the mid-stroke.

- Scotch Yoke: This mechanism converts linear piston motion to rotary motion via a sliding yoke. The geometry generates a U-shaped torque curve, providing maximum torque at the beginning and end of the stroke—exactly where most valves need it. This design is preferred for large valves (24-inch and above) and high-torque applications, allowing for a smaller cylinder size relative to the valve.

- Rotary Vane: A vane actuator uses a single moving part (the vane) directly attached to the shaft within a pie-shaped chamber. This design minimizes backlash and friction, making it exceptional for high-cycle and precise modulating applications. It typically offers a long service life but may have lower torque limitations compared to massive scotch yoke units.

2. Duty Cycle and Hysteresis

In water filtration, backwash valves cycle frequently. In aeration control, valves modulate continuously to maintain Dissolved Oxygen (DO) setpoints.

- Modulating Service: Requires low friction and low hysteresis (the lag between the command signal and physical movement). Actuators with rolling diaphragms or precision-machined vanes are often superior here to piston seals that suffer from “stiction” (static friction).

- Isolation Service: Focus is on tight shutoff capability. The actuator must provide sufficient spring force (in spring-return models) to hold the valve closed against full line pressure during a power or air loss.

3. Environmental Considerations and Materials

Water and wastewater environments are aggressive.

- Corrosion Protection: Aluminum housings must be hard-anodized or epoxy-coated (e.g., thermally bonded polyester). In highly corrosive areas like chemical storage or sludge dewatering, 316 stainless steel housings or specialized coatings (like PTFE impregnation) are specified.

- Ingress Protection: Actuators should meet IP66/IP67 or NEMA 4X/6 standards. Water ingress into the spring housing is a common failure mode, leading to spring corrosion and eventual failure.

- Temperature: While most municipal plants operate in ambient ranges, outdoor installations in northern climates require low-temperature seals (silicone or specialized nitrile) to prevent air leakage in sub-zero conditions.

4. Air Supply Quality

Pneumatic actuators are only as reliable as the air supply.

- Pressure: Standard plant air is usually 80–100 psi. Sizing must be calculated based on the minimum available pressure (often 60 psi to be safe) to ensure the valve can still operate during system pressure dips.

- Filtration: Particulates and moisture are destructive. Specifications should require local filter-regulators. Dew points must be suppressed below the lowest ambient temperature to prevent freezing in the lines.

5. Fail-Safe Requirements

Engineers must determine the failure mode: Fail-Open, Fail-Close, or Fail-Last-Position.

- Spring Return (SR): Mechanical springs force the actuator to a safe position upon air loss. This is the standard for critical isolation valves. The spring sizing is critical; “End of Spring” torque must exceed the valve’s reseating torque.

- Double Acting (DA): Uses air to open and air to close. Upon air loss, the valve remains free or drifts. If a specific fail position is required with DA actuators, a reserve air volume tank and trip valve system must be engineered.

6. Lifecycle Cost and Maintenance

The purchase price of an actuator is often 10-20% of the total cost of ownership.

- Seal Wear: O-rings and dynamic seals wear out. Designs that allow for easy seal replacement without removing the actuator from the valve reduce maintenance OPEX.

- Air Consumption: Large actuators consume significant air volumes. Inefficient designs increase compressor energy costs. Vane actuators often have lower volumetric requirements than equivalent rack and pinion units.

Comparison Table: Pneumatic Actuator OEMs

The following table is intended to assist consulting engineers and utility operators in evaluating the primary characteristics of the top OEMs in the pneumatic actuator market. This is not a ranking from “best” to “worst,” as applicability depends entirely on the specific duty—a high-speed filter backwash application has different requirements than a 48-inch pump isolation valve.

Note: “Primary Mechanism” refers to the core technology the OEM is most renowned for in the municipal sector, though they may offer other types.

| OEM Name | Primary Mechanism Focus | Key Engineering Strength | Best-Fit Application | Maintenance Considerations |

|---|---|---|---|---|

| Kinetrol | Rotary Vane | Single moving part; exceptional cycle life and minimal friction/backlash. | High-cycle filter backwash; Precision modulation. | Modular design allows module replacement; extremely long intervals between service. |

| Bray | Rack & Pinion / Scotch Yoke | Broad compatibility; standardized mounting (NAMUR/ISO); extensive accessory integration. | General plant isolation; HVAC; Chemical feed (smaller lines). | Field-repairable with standard O-ring kits; hard anodized surfaces resist wear. |

| Rotork | Scotch Yoke / Rack & Pinion | Heavy-duty torque output; rigorous environmental sealing (IP68 options); robust pneumatic controls. | Large diameter transmission mains; Critical pump isolation; High-pressure service. | Modular construction allows cylinder swapping for pressure adjustments; requires robust support for weight. |

| Emerson Bettis | Scotch Yoke | Legendary reliability in harsh environments; Safety Integrity Level (SIL) capabilities. | Emergency Shutdown (ESD) valves; Extreme service conditions; Large diameter valves. | Designed for minimal maintenance; “fit and forget” philosophy for critical assets. |

| AUMA | Part-Turn Pneumatic / Gearboxes | Integration with complex control networks; high precision positioning. | Applications requiring sophisticated feedback/diagnostics alongside pneumatic power. | Often involves pairing pneumatic drivers with high-spec gearboxes; maintenance focuses on linkage and controls. |

Top OEM Manufacturers

The following manufacturers represent the tier-one standard for pneumatic actuation in the water and wastewater industry. Selection should be based on specific engineering requirements for torque, duty cycle, and environmental resistance.

Kinetrol

Kinetrol is unique in the actuation world due to its steadfast adherence to the rotary vane principle. Unlike rack and pinion designs which convert linear motion to rotary, the Kinetrol vane is a true rotary actuator. It consists of a single moving part—a vane integral with the shaft—moving within a shaped cavity.

Engineering Analysis: The primary advantage of the vane design is longevity. Without gears to wear or multiple pistons to seal, Kinetrol actuators are capable of millions of cycles, making them the premier choice for rapid-cycling applications like pulsing filters or sequence batch reactors (SBR). The lack of motion conversion linkage means there is virtually zero backlash, resulting in extremely precise control for modulating valves.

Municipal Application: In water treatment plants, Kinetrol is frequently specified for filter galleries where space is tight (vane actuators are generally more compact than rack and pinion) and where reliability is paramount. Their modular “add-on” system allows spring return units, limit switches, and positioners to be stacked on the basic actuator, simplifying inventory for maintenance departments.

Bray

Bray is a dominant force in the flow control industry, particularly renowned for the tight integration of their actuators with their butterfly valves. Their Series 92/93 pneumatic actuators are rack and pinion designs that have become an industry standard for general service applications.

Engineering Analysis: Bray actuators typically feature two opposing pistons with rack gears that drive a central pinion. This design provides constant torque output throughout the stroke. The engineering focus is on material durability; housings are extruded aluminum with hard anodizing, often followed by a polyester powder coat for corrosion resistance. They utilize acetal bearings and guides to prevent metal-to-metal contact between the piston and cylinder bore, extending seal life.

Municipal Application: Bray is the “workhorse” specification for general isolation in wastewater plants, including aeration lines, supernatant decant, and sludge handling. Their widespread distribution network ensures that parts and replacements are readily available, reducing supply chain risks for public utilities. They are also frequently used in HVAC and non-process water applications within the plant.

Rotork

Rotork is synonymous with heavy-duty actuation. While perhaps best known for electric actuators, their fluid power division produces some of the most robust pneumatic actuators available, specifically the CP, GP, and RC ranges. They specialize in scotch yoke mechanisms for high-torque applications.

Engineering Analysis: The scotch yoke design employed by Rotork (particularly in the CP and GP ranges) generates a torque curve that is high at the “break” and “end” positions. This is mechanically efficient for seating and unseating large butterfly and ball valves which may have been stationary for long periods. Rotork emphasizes environmental protection, with cylinders typically manufactured from carbon steel (electroless nickel plated) or stainless steel, ensuring survival in salt-laden or corrosive atmospheres.

Municipal Application: Rotork is the preferred choice for large-scale water transmission mains, intake structures, and pump discharge isolation valves where the valve size exceeds 24 inches. Their actuators are often found in critical infrastructure where failure is not an option, such as emergency isolation valves or flood control gates.

Emerson Bettis

Bettis, a brand under Emerson, carries a heritage deeply rooted in the oil and gas industry, which translates to “over-engineered” reliability for water applications. Their reputation is built on the scotch yoke design, a technology they pioneered and refined.

Engineering Analysis: Bettis actuators (such as the G-Series and C-Series) are designed to withstand extreme vibration, shock, and environmental stress. They offer high-performance sealing systems and modular construction that allows the power cylinder and spring cartridge to be removed or swapped safely. Their torque outputs can be massive, suitable for the largest valves in existence. The safety factors built into Bettis designs often exceed municipal requirements, providing a high margin of error.

Municipal Application: In the municipal sector, Bettis is often seen in high-pressure pumping stations, desalination plants (where corrosion resistance is critical), and large-diameter influent/effluent lines. They are also a top choice for ESD (Emergency Shutdown) applications where fast, guaranteed closure is required to protect downstream infrastructure.

AUMA

AUMA is globally recognized for its electric modular actuators, but they maintain a significant presence in the pneumatic sector, often through specific product lines or by pairing pneumatic drivers with their high-precision gearboxes.

Engineering Analysis: AUMA’s approach to pneumatic actuation often focuses on the interface between the pneumatic muscle and the control system. Their solutions emphasize precise positioning and feedback. When AUMA gearboxes are paired with pneumatic drives, they provide a very stable, self-locking (in some worm gear configurations) solution that prevents valve movement under fluctuating hydrodynamic torque.

Municipal Application: AUMA pneumatic solutions are often found in European-designed plants or facilities requiring high levels of automation integration. They are suitable for complex modulation tasks where the actuator must integrate seamlessly with a larger Profibus or Modbus control network, necessitating high-quality positioners and feedback units mounted to the pneumatic drive.

Application Fit Guidance

Matching the OEM strength to the specific plant application is key to specification success.

Municipal Water Distribution

For distribution networks involving large diameter ball or butterfly valves, Rotork and Emerson Bettis are preferred. Their scotch yoke designs provide the necessary breakout torque to overcome the stiction of valves that may sit in one position for months. The rugged construction suits underground vaults or exposed outdoor service.

Municipal Wastewater Treatment (Inside Fence)

For general process isolation (aeration, sludge, clarifiers), Bray is widely utilized due to cost-effectiveness and the widespread availability of parts. The rack and pinion design is sufficient for the torque requirements of standard 3-12 inch valves.

Filtration and High-Cycle Applications

For filter backwash valves or SBR decanters that cycle dozens of times a day, Kinetrol is the engineer’s choice. The rotary vane design eliminates the wear points found in rack and pinion or scotch yoke linkages, drastically extending the Mean Time Between Failures (MTBF).

Corrosive and Aggressive Media

In areas with high H2S concentrations (headworks, solids handling), or chemical feed (ferric chloride, hypochlorite), the exterior coating of the actuator is as important as the internals. All listed OEMs offer specific corrosion-resistant packages (stainless steel or epoxy coated). However, Kinetrol’s epoxy enamel finish and simple external geometry (fewer crevices) make it particularly resilient in washdown areas.

Automated vs. Manual Integration

For highly automated systems requiring smart positioners (HART, Foundation Fieldbus), AUMA and Rotork excel in providing integrated control heads that mount directly to the pneumatic actuator, providing rich diagnostics back to SCADA regarding valve signature and air pressure status.

Engineer & Operator Considerations

Even the highest quality OEM actuator will fail if applied or maintained incorrectly.

Installation Best Practices

Mounting Kits: The bracket and coupling connecting the actuator to the valve stem are critical. Engineers should specify rigid, machined brackets rather than stamped metal. Misalignment here causes side-loading on the valve stem and actuator bearing, leading to premature packing leaks.

Air Lines: Use stainless steel or high-grade polymer tubing. Copper tubing, while traditional, can work harden and crack under vibration. Ensure the air supply line is sized correctly (often 1/2″ or larger for big actuators) to prevent air starvation during rapid stroking.

Common Specification Mistakes

Undersizing for Safety Factor: Relying on the valve manufacturer’s “operating torque” without adding a safety factor (typically 1.25x or 1.5x) is a recipe for failure. Valve torque increases over time due to scale buildup and seal hardening.

Ignoring “Fail” Position: Specifying a double-acting actuator for a valve that absolutely must close during a power outage is a critical error. Always specify spring-return for fail-safe applications unless a dedicated air receiver tank is engineered.

Maintenance and Spare Parts

Access: Install actuators with maintenance in mind. Can the cover be removed to change springs? Is the positioner at eye level?

Spring Fatigue: In spring-return units, springs can fatigue over years of service or corrode if the breather vent draws in moisture. Operators should inspect breather ports regularly to ensure they are not clogged (by insects or paint) or positioned to draw in rain.

Long-Term Reliability

Operational experience suggests that the primary killer of pneumatic actuators is not the actuator itself, but the air quality. Water in the air line washes away factory grease; oil from compressor blow-by can swell EPDM seals. A robust preventative maintenance program must focus on the air dryers and filter-regulators upstream of the actuator.

Conclusion

For municipal water and wastewater applications, the pneumatic valve actuator is a device of deceptive simplicity. While less complex than its electric counterpart, it requires rigorous engineering attention regarding torque physics, air quality, and environmental suitability.

There is no single “best” manufacturer. Kinetrol offers unmatched longevity for high-cycle modulation; Bray delivers reliable, standardized performance for general process isolation; Rotork and Emerson Bettis provide the brute force and ruggedness required for critical, large-diameter infrastructure; and AUMA bridges the gap between pneumatic power and sophisticated control integration.

Consulting engineers and utility decision-makers must evaluate these OEMs based on the specific lifecycle requirements of the application—balancing initial capital cost against the long-term operational costs of air consumption, maintenance, and potential downtime. By matching the mechanical strengths of the actuator design to the hydraulic realities of the system, utilities can ensure decades of reliable operation.