Hydro Gate vs Golden Harvest for Gates: Pros/Cons & Best-Fit Applications

Introduction

For municipal and industrial engineers, the failure of a water control gate is rarely a minor operational annoyance; it is a critical vulnerability that can lead to catastrophic flooding, regulatory non-compliance, and significant safety hazards. While pumps often receive the lion’s share of attention in hydraulic modeling, the static and dynamic isolation provided by sluice and slide gates is fundamental to process integrity. A recurring decision point in facility design and upgrade cycles involves selecting the right manufacturer and technology platform. This analysis focuses on the engineering considerations surrounding Hydro Gate vs Golden Harvest for Gates: Pros/Cons & Best-Fit Applications.

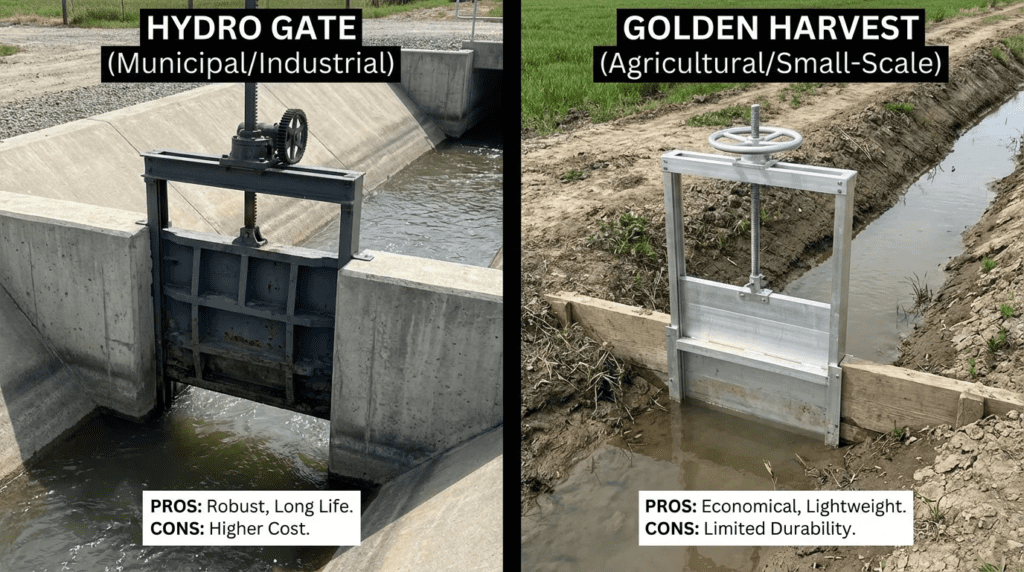

Hydro Gate (a Müller Water Products brand) and Golden Harvest are two industry stalwarts, often representing slightly different philosophical approaches to water control. Hydro Gate is historically synonymous with heavy-duty cast iron sluice gates (AWWA C560), representing the “traditional” robust approach favored for deep tunnel and high-head applications. Golden Harvest, while offering a broad range, has carved a massive niche in high-precision fabricated stainless steel and aluminum gates (AWWA C561 and C562), favoring modularity, leakage performance, and customization.

The choice between these manufacturers—and more importantly, the technologies they represent—is not merely about brand preference. It involves analyzing unseating head requirements, corrosion potential, actuation forces, and lifecycle maintenance costs. A poor specification that calls for a fabricated gate where a cast iron gate is required (or vice versa) can result in seal failure, structural deflection, or excessive maintenance burdens. This article aims to equip consulting engineers and utility decision-makers with the technical criteria necessary to navigate the Hydro Gate vs Golden Harvest for Gates: Pros/Cons & Best-Fit Applications landscape effectively.

How to Select and Specify Water Control Gates

Selection of the appropriate gate requires a rigorous analysis of the hydraulic profile and the physical constraints of the civil structure. Engineers must move beyond “boiler plate” specifications and evaluate the specific constraints of the application.

Duty Conditions & Operating Envelope

The primary driver in the selection process is the relationship between the gate and the hydraulic head. Engineers must explicitly define the seating head (pressure pushing the gate into the frame/seal) and unseating head (pressure pushing the gate away from the frame).

- Seating vs. Unseating: Cast iron gates (typically associated with Hydro Gate’s heavy-duty lines) rely on machined bronze wedges and heavy mass to handle immense unseating heads with minimal deflection. Fabricated gates (a strong suit of Golden Harvest) utilize UHMWPE (Ultra-High Molecular Weight Polyethylene) sliding surfaces. While modern fabricated gates are robust, high unseating heads require substantial reinforcement ribs, which can affect flow characteristics and cost.

- Modulating vs. Isolation: If the gate is intended for flow modulation (throttling), the gate must be designed to resist vibration and cavitation. Cast iron’s dampening properties are often superior in severe throttling applications, whereas fabricated gates must be carefully analyzed for natural frequency to avoid resonance.

- Flow Direction: Is the flow uni-directional or bi-directional? Bi-directional applications (e.g., tidal gates or equalization basins) generally favor the wedging action of cast iron or high-specification fabricated gates with active seating mechanisms.

Materials & Compatibility

The material choice dictates the lifespan of the asset and its suitability for the process environment. This is often where the Hydro Gate vs Golden Harvest for Gates: Pros/Cons & Best-Fit Applications decision is made.

- Cast Iron (ASTM A126 Class B): The traditional choice for raw sewage and heavy-duty intakes. It offers excellent vibration dampening and corrosion resistance when properly coated. However, it is heavy and requires significant infrastructure for installation.

- Stainless Steel (304L/316L): The standard for modern treatment plants, particularly in aeration basins and UV channels. It offers superior corrosion resistance without the need for coating maintenance. Passivation is critical to prevent surface rust.

- Aluminum (6061-T6): Frequently used in stormwater and clean water applications due to its light weight and lower cost. However, it is generally unsuitable for high-pH wastewater or environments with significant grit, which can abrade the softer metal.

- Galvanic Corrosion: Engineers must be vigilant about dissimilar metals. Pairing a stainless steel gate with a carbon steel thimble in a highly conductive wastewater electrolyte can lead to rapid failure of the anodic component.

Hydraulics & Process Performance

The physical presence of the gate affects the hydraulic grade line. Manufacturers like Hydro Gate and Golden Harvest provide specific coefficients for head loss, but these are often based on fully open conditions.

For weir gates (downward opening), the accuracy of level control is paramount. Fabricated gates often allow for tighter manufacturing tolerances on weir plates, making them ideal for decanters or precise level control in SBR (Sequencing Batch Reactor) basins. Leakage rates are another critical hydraulic factor. AWWA C561 (Fabricated) generally allows for lower leakage rates than AWWA C560 (Cast Iron) due to the nature of polymeric seals versus metal-to-metal seating, though both can be specified to high standards.

Installation Environment & Constructability

Constructability is a major differentiator. A 72-inch cast iron sluice gate may weigh several tons, requiring a crane, a thimble wall penetration, and a complex grouting procedure. A comparable fabricated stainless steel slide gate might be significantly lighter and anchor-bolt mounted directly to the concrete face.

In retrofit applications where crane access is limited (e.g., inside a crowded pump station), the lighter weight and modularity of fabricated gates (Golden Harvest’s forte) often provide a decisive advantage. Conversely, for new construction of deep pump stations where the gate is embedded in the initial concrete pour, the robust thimble-mount design of a heavy cast iron gate (Hydro Gate’s forte) ensures long-term structural integrity.

Reliability, Redundancy & Failure Modes

Failure modes differ between technologies. Cast iron gates can suffer from graphitic corrosion over decades, eventually losing structural strength while retaining shape. They can also crack under sudden shock loads (water hammer). Fabricated gates are more ductile but can suffer from weld fatigue or seal delamination if not properly maintained.

Reliability Data:

- MTBF (Mean Time Between Failures): Properly specified gates of either brand often exceed 20-30 years for the gate body. The actuation system is usually the limiting factor.

- Common Failure Point: The stem nut (operating nut). As the sacrificial wear component, usually bronze, it will strip if the gate is over-torqued or if the stem is not lubricated.

Maintainability, Safety & Access

Operator safety is paramount. Rising stem gates provide a visual indication of gate position, which is a critical safety feature. Non-rising stem gates require position indicators. Maintenance access for stem lubrication is essential. If the operating floor is 30 feet above the gate, intermediate stem guides are required to prevent column buckling. The spacing of these guides is a function of the stem diameter (L/r ratio), which the engineer must verify against the manufacturer’s recommendation.

Lifecycle Cost Drivers

When analyzing Hydro Gate vs Golden Harvest for Gates: Pros/Cons & Best-Fit Applications, the total cost of ownership (TCO) often diverges from the initial CAPEX.

- CAPEX: Fabricated stainless gates are generally less expensive to purchase and install than cast iron sluice gates, primarily due to lower weight and the elimination of wall thimbles.

- OPEX: Cast iron gates may require periodic abrasive blasting and re-coating every 15-20 years, a significant expense. Stainless steel gates largely eliminate this cost but may require more frequent seal replacements (every 7-10 years) depending on the abrasion level of the fluid.

Comparison Tables

The following tables provide a structured comparison to assist engineers in differentiating between the typical offerings associated with these manufacturers and technologies. While both companies offer a range of products, their core strengths and historical market positions differ. Use these tables to align product selection with application requirements.

Table 1: Technology & Manufacturer Focus Comparison

| Feature / Criteria | Hydro Gate (Traditional Strength) | Golden Harvest (Traditional Strength) | Engineering Implication |

|---|---|---|---|

| Primary Material Focus | Cast Iron / Ductile Iron (Heavy Duty) | Fabricated Stainless Steel & Aluminum | Cast iron for mass/dampening; SS for corrosion resistance/light weight. |

| Applicable AWWA Standard | AWWA C560 (Cast Iron Sluice Gates) | AWWA C561 (Fab SS) & C562 (Alum) | C560 implies metal-to-metal seating; C561 implies polymeric sealing. |

| Sealing Mechanism | Bronze Wedges (Metal-to-Metal) | UHMWPE / EPDM / Neoprene (Polymeric) | Metal seats are durable but leak more; Polymer seats are tight but wear faster. |

| Typical Leakage Rate | 0.1 gpm/ft of seating perimeter (Standard) | 0.05 gpm/ft or less (High Performance) | Fabricated gates often specified for tighter leakage requirements. |

| Unseating Head Capacity | Excellent (Due to wedge system) | Good (Requires stiffeners/reinforcement) | Cast iron preferred for extreme unseating head scenarios (>50 ft). |

| Installation Complexity | High (Requires thimbles, grout, cranes) | Moderate (Anchor bolts, lighter weight) | Fabricated gates reduce civil works costs and install time. |

Table 2: Application Fit Matrix

| Application Scenario | Best-Fit Technology | Why? | Key Specification Constraint |

|---|---|---|---|

| Deep Tunnel Isolation | Cast Iron Sluice Gate | Extreme head pressures, difficult access, 50+ year lifespan required. | Must specify unseating head rating equal to full tunnel depth. |

| UV Disinfection Channels | Fabricated Stainless Steel | Level control accuracy, zero contamination, low head pressure. | Specify 316L SS to prevent rouge/corrosion interfering with UV. |

| Headworks / Grit Chamber | Cast Iron OR Heavy Fab SS | Abrasion resistance is key. Grit destroys soft seals. | If fabricated, specify flush-bottom seal to prevent grit trap. |

| Stormwater Outfall | Fabricated Aluminum/SS | Intermittent use, large size, low pressure. | Ensure flap gates have break-open force calculations. |

| Existing Channel Retrofit | Self-Contained Fab SS | No existing superstructure; mounts directly to channel walls. | Verify channel wall structural integrity for reaction loads. |

Engineer & Operator Field Notes

Real-world performance is often determined by the quality of installation and maintenance rather than the manufacturing defect. The following notes are compiled from field experiences with both Hydro Gate and Golden Harvest installations.

Commissioning & Acceptance Testing

Commissioning a gate involves more than just opening and closing it. The Factory Acceptance Test (FAT) should verify material certifications and dimensional tolerances. However, the Site Acceptance Test (SAT) is where the rubber meets the road.

- Leakage Testing: The most contentious part of commissioning. The gate must be subjected to the full design head. Engineers should specify a “dry field test” using feeler gauges to check seat contact before water is introduced. When testing with water, leakage should be measured using a calibrated container and stop-watch, normalized to gallons per minute per foot of seal perimeter.

- Amperage Draw: During SAT, record the motor amperage during the full travel of the gate. Spikes in amperage often indicate binding in the guides or a bent stem. This establishes a baseline for future predictive maintenance.

Do not overlook the actuator gearing. A common mistake is specifying an actuator that moves the gate too fast (causing water hammer) or too slow (delaying process reaction). For large gates, travel speeds of 12 inches per minute are typical. Verify this against the total travel distance to ensure cycle times meet operational protocols.

Common Specification Mistakes

In the context of Hydro Gate vs Golden Harvest for Gates: Pros/Cons & Best-Fit Applications, errors often stem from mismatched expectations.

- Over-Specifying Leakage: Demanding “zero leakage” is engineering malpractice. All slide gates leak to some degree. Specifying limits tighter than AWWA standards drives up cost exponentially without operational benefit.

- Ignoring Stem Buckling: For deep channels, the unsupported length of the stem is critical. Engineers often forget to specify the location and number of intermediate stem guides, leading to stems that bow under compressive closing loads.

- Material Mismatches: Specifying a 304 SS gate in a coastal wastewater plant (high chlorides) invites pitting corrosion. 316L or Duplex Stainless Steel should be standard for these environments.

O&M Burden & Strategy

Maintenance teams prefer equipment that is “set and forget,” but gates require care.

- Stem Lubrication: The number one cause of gate failure is a dry stem. Automated lubrication systems are highly recommended for critical gates.

- Exercising: Gates that remain in one position for years will freeze. A quarterly exercise program (moving the gate 10-20% of travel) keeps the threads clean and the seals pliable.

- Seal Adjustment: Fabricated gates often have adjustable wedges or seal retainers. Operators must be trained on how to tighten these without over-compressing the seal, which increases friction and motor load.

Troubleshooting Guide

Symptom: Gate is binding / Motor trips on overload.

- Root Cause 1: Debris lodged in the bottom seal. (Common in grit chambers).

- Root Cause 2: Stem nut wear. As threads wear, friction increases dramatically.

- Root Cause 3: Frame distortion. If the concrete wall has settled or the anchor bolts were over-torqued, the frame may have twisted, pinching the slide.

Design Details & Calculations

Accurate sizing of the gate and its actuation system is a fundamental engineering responsibility. Relying solely on the vendor to size the actuator puts the engineer at risk if the assumptions are incorrect.

Sizing Logic & Methodology

The force required to operate a gate is a summation of several resistance factors. The general formula for calculating the required stem thrust ($F_{total}$) is:

$F_{total} = F_{f} + F_{w} + F_{h} + F_{s}$

- $F_{f}$ (Friction Force): Derived from the hydrostatic load multiplied by the coefficient of friction between the slide and the seat.

- $F_{f} = mu times P times A$

- Where $mu$ is the friction coefficient (typically 0.35 for bronze-to-bronze, 0.2 for UHMWPE-to-SS).

- $P$ is the pressure (Head).

- $A$ is the area.

- $F_{w}$ (Weight): The weight of the slide and the stem.

- $F_{h}$ (Hydrostatic Uplift/Downpull): Forces generated by water flow across the bottom of the gate (significant in throttling).

- $F_{s}$ (Seating/Unseating Force): The force required to wedge the gate into the seated position.

The force required to start moving a gate (breakaway) is typically 1.5 to 2 times the running force. Engineers must ensure the electric actuator is sized for this peak starting torque, not just the running load.

Specification Checklist

When drafting the RFP or technical specification for Hydro Gate or Golden Harvest products, ensure the following are explicitly defined:

- Opening Size (W x H): Clearly state if this is the clear opening or the frame size.

- Design Head: Max seating and max unseating head in feet of water column.

- Invert Elevation: Critical for stem length calculations.

- Operating Floor Elevation: Determines pedestal height and stem length.

- Actuation Type: Manual (Handwheel/Crank), Electric (Voltage/Phase), or Hydraulic.

- Mounting Style: Wall mount (anchor bolt), Thimble mount (flange), or Embedded.

- Leakage Class: Reference AWWA C560 or C561 specific limits.

Standards & Compliance

Adherence to standards ensures interchangeability and quality.

- AWWA C560: Standard for Cast-Iron Slide Gates. Focuses on material thickness, safety factors (typically 5:1), and bronze seating surfaces.

- AWWA C561: Standard for Fabricated Stainless Steel Slide Gates. Focuses on structural calculations to prevent deflection that would compromise the seal.

- AWWA C562: Standard for Fabricated Aluminum Slide Gates. Similar to C561 but addresses aluminum-specific properties.

- NSF/ANSI 61: Mandatory for any gate in contact with potable water.

Frequently Asked Questions

What is the primary difference between Hydro Gate and Golden Harvest regarding gate types?

While both manufacturers offer broad product lines, Hydro Gate is historically best known for heavy-duty cast iron sluice gates (AWWA C560) used in high-head and deep infrastructure applications. Golden Harvest is widely recognized for expertise in fabricated stainless steel and aluminum gates (AWWA C561/C562), often preferred for their modularity, lower leakage rates in low-head applications, and customization capabilities.

How do you select between a Cast Iron and a Fabricated Stainless Steel gate?

Select Cast Iron (Hydro Gate style) for applications with high unseating heads (>20-30 ft), severe vibration potential, or where longevity exceeding 50 years without seal replacement is prioritized. Select Fabricated Stainless Steel (Golden Harvest style) for applications requiring tight leakage control, corrosion resistance without coating maintenance, ease of installation (lighter weight), or custom geometries (e.g., weird channel sizes).

What is the typical lifespan of a sluice gate in wastewater service?

A properly maintained cast iron sluice gate can last 50+ years; some have been in service for over 80 years. Fabricated stainless steel gates typically have a design life of 25-40 years, with seal replacements required every 7-15 years depending on usage frequency and grit abrasion. The actuator usually requires replacement or overhaul every 15-20 years.

Why does unseating head matter in the Hydro Gate vs Golden Harvest selection?

Unseating head pushes the gate away from its frame. Cast iron gates utilize rigid wedges and heavy metal frames to mechanically lock the gate against the seal, handling high unseating pressure well. Fabricated gates rely on the stiffness of the slide and frame assembly; under high unseating pressure, they may deflect, causing seal separation. Therefore, for high unseating head applications, cast iron or heavily reinforced fabricated gates are necessary.

How often should water control gates be maintained?

Stems should be cleaned and lubricated semi-annually (every 6 months) or per manufacturer recommendations. The gate should be fully cycled (opened and closed) at least quarterly to prevent seizing. Gearboxes on electric actuators should have oil levels checked annually and changed every 5 years or based on the manufacturer’s duty cycle recommendations.

Can I replace an old cast iron gate with a new fabricated one?

Yes, this is a common retrofit strategy. However, the engineer must verify the anchor bolt pattern and the flatness of the existing concrete wall. Fabricated gates are more flexible than cast iron and require a flat mounting surface to seal properly. Often, a layer of non-shrink grout is required between the wall and the new gate frame to ensure a plumb and flush installation.

Conclusion

Key Takeaways

- Duty Defines Design: Do not default to “Standard Sluice Gate.” Analyze Seating vs. Unseating head explicitly for every gate schedule line item.

- Material Matters: Use Cast Iron (AWWA C560) for heavy, high-head, long-life deep infrastructure. Use Fabricated Stainless (AWWA C561) for lighter, corrosion-resistant, high-sealing applications.

- Installation Costs: Fabricated gates (Golden Harvest style) significantly reduce civil constraints and crane requirements compared to heavy Cast Iron (Hydro Gate style).

- Maintenance Trade-off: Cast iron requires painting but has durable metal seats. Stainless requires no painting but has softer polymer seals that wear faster.

- Actuator Sizing: Verify breakaway torque calculations. Undersized actuators are the most common cause of early operational failure.

The debate surrounding Hydro Gate vs Golden Harvest for Gates: Pros/Cons & Best-Fit Applications ultimately serves as a proxy for the broader engineering choice between heavy-duty cast construction and modern custom fabrication. Hydro Gate’s portfolio, with its deep roots in cast iron, remains the benchmark for applications where mass, vibration dampening, and extreme longevity under high pressure are non-negotiable. Golden Harvest’s agility in the fabricated stainless steel market offers engineers superior options for leakage control, corrosion resistance, and retrofit versatility.

For the consulting engineer or plant director, the “best” choice is never universal. It is found in the specific hydraulic profile of the channel, the chemical composition of the fluid, and the long-term operational capabilities of the maintenance staff. By adhering to the selection criteria, calculation methods, and installation best practices outlined in this guide, utilities can ensure that their isolation assets perform reliably for decades, regardless of the nameplate on the frame.