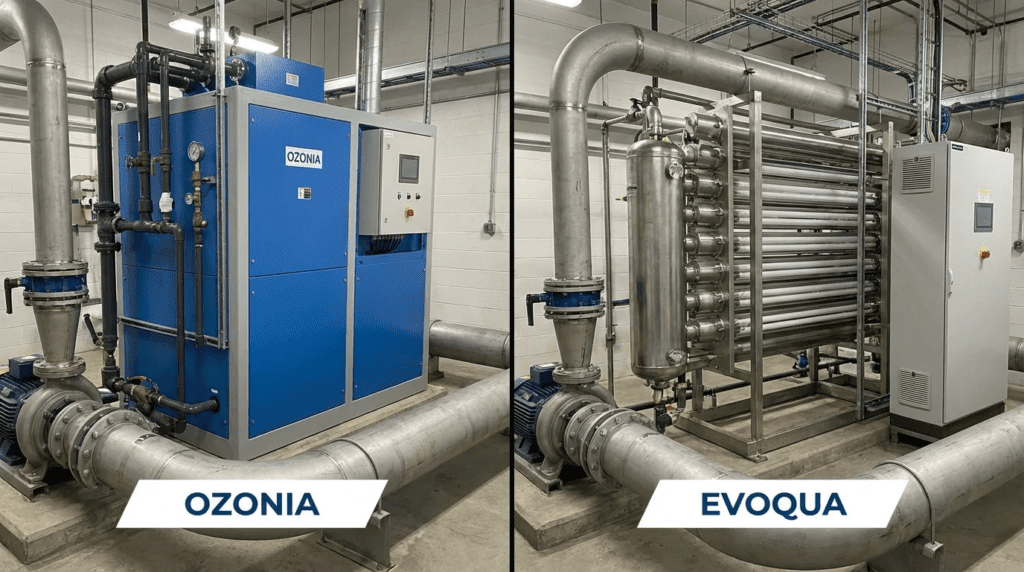

Ozonia vs Evoqua Disinfection Equipment: Comparison & Best Fit

Introduction

In the landscape of advanced water and wastewater treatment, few decisions impact long-term compliance and operational expenditure as heavily as the selection of primary disinfection and oxidation technologies. For decades, the market has been dominated by a select few manufacturers, leading engineers to frequently conduct an Ozonia vs Evoqua Disinfection Equipment: Comparison & Best Fit analysis during the preliminary design and equipment selection phases. However, recent industry consolidation—specifically Suez (owning Ozonia) integrating into Veolia, and Evoqua being acquired by Xylem—has complicated the specification landscape. Engineers are no longer just selecting equipment; they are navigating complex legacy portfolios that merge ozone generation, ultraviolet (UV) disinfection, and gas chlorination technologies.

The stakes in this selection process are high. Disinfection systems are the final barrier protecting public health against pathogens like Cryptosporidium and Giardia. Furthermore, in industrial and potable reuse applications, these systems are critical for the destruction of emerging contaminants via Advanced Oxidation Processes (AOP). A poor specification does not merely result in a slightly inefficient plant; it can lead to massive energy waste (as ozone and UV are energy-intensive), inability to meet log-inactivation credits, or catastrophic downtime due to proprietary parts obsolescence.

This article provides a rigorous, engineer-to-engineer analysis of these two technology giants. We move beyond marketing brochures to examine the hydraulic constraints, dielectric reliability, maintenance burdens, and control interfaces that define real-world performance. Whether you are retrofitting a 50 MGD municipal plant or designing a compact industrial effluent polishing system, understanding the nuances between these platforms is essential for operational success.

How to Select and Specify Disinfection Systems

When evaluating an Ozonia vs Evoqua Disinfection Equipment: Comparison & Best Fit scenario, the engineering team must look past nameplate capacity. The selection process requires a granular review of the operating envelope, material science, and integration capabilities. The following criteria define the specification framework.

Duty Conditions & Operating Envelope

The first step in specification is defining the operational boundaries. For ozone systems, this involves not just the ozone dosage (mg/L) but the ozone concentration (% by weight). Ozonia (Veolia) has historically pushed the envelope on high-concentration ozone generation (up to 12-14% wt), which significantly reduces the required feed gas flow and oxygen demand. Evoqua’s portfolio, incorporating legacy Pacific Ozone and Wallace & Tiernan technologies, often offers modular flexibility that fits variable duty points well.

For UV systems, the critical parameter is UV Transmittance (UVT). Engineers must evaluate the equipment’s ability to maintain dose pacing during low UVT events (e.g., storm flows).

- Turndown Ratio: Can the power supply units (PSUs) turndown linearly from 100% to 10%? Step-less dimming is critical for energy conservation in both UV and Ozone.

- Temperature Sensitivity: Ozone generator dielectrics are highly sensitive to cooling water temperature. Specifications must define the maximum cooling water temperature (typically 30°C or 35°C) and the required derating factor if ambient conditions exceed this.

Materials & Compatibility

Material selection is non-negotiable in disinfection environments. Ozone is a powerful oxidant that degrades standard elastomers rapidly.

- Ozone Generators: Look for 316L Stainless Steel vessel construction as a baseline. The dielectric tubes—the heart of the generator—vary between manufacturers. Ozonia typically utilizes a glass/ceramic hybrid dielectric designed for thermal shock resistance. Evoqua’s various product lines may use ceramic or glass dielectrics depending on the specific legacy brand (e.g., PCI vs. Pacific).

- UV Reactors: 316L SS is standard, but the internal surface finish (Ra value) affects hydraulic friction and bio-fouling. For aggressive wastewater, Super Duplex stainless steel may be required to prevent chloride stress corrosion cracking, particularly in coastal regions.

When specifying ozone generators, require a “fuse protection” system for individual dielectrics. If one tube fails, the individual fuse should blow, allowing the generator to continue operating at slightly reduced capacity rather than tripping the entire unit.

Hydraulics & Process Performance

Hydraulic profile analysis differs significantly between Ozone and UV.

UV Systems: The head loss across the reactor is a critical constraint. Low-pressure high-output (LPHO) systems often have different head loss characteristics compared to Medium Pressure (MP) systems due to lamp density and arrangement (staggered vs. inline). The specification must dictate the maximum allowable head loss to prevent upstream hydraulic bottlenecks.

Ozone Systems: The focus is on Gas Transfer Efficiency (GTE). The contactor design (often concrete baffles) interacts with the diffusion system. Whether using fine bubble diffusers or side-stream injection (Venturi), the equipment selection impacts the required contact time (CT). Sidestream injection, common in modern designs, requires high-pressure motive water pumps, which changes the energy balance compared to diffusers.

Installation Environment & Constructability

Space constraints often dictate the winner in the Ozonia vs Evoqua Disinfection Equipment: Comparison & Best Fit analysis.

- Footprint: High-concentration ozone generators are generally more compact. However, the ancillary equipment (Liquid Oxygen [LOX] tanks, evaporators, destruct units) consumes significant square footage.

- Skid vs. Stick-Built: Evoqua has a strong history of providing pre-packaged, skid-mounted solutions (especially via their Pacific Ozone line) which reduces field installation labor. Ozonia units for large municipalities are often large vessels requiring significant on-site mechanical assembly and piping.

- HVAC Requirements: Ozone generators dissipate heat into the room, and ozone monitors require specific air change rates for safety. UV ballasts also generate significant heat; specifications must account for control panel cooling (air-conditioned cabinets) in hot climates.

Reliability, Redundancy & Failure Modes

In municipal applications, “N+1” redundancy is standard. However, the definition of N+1 varies.

- Power Supply Units (PSU): Modern designs often use modular PSUs. If one power module fails, the generator/reactor loses only a fraction of its capacity. Specifications should favor modular PSU architectures over monolithic power supplies to improve Mean Time Between Failures (MTBF).

- Cleaning Systems: For UV, the automatic wiping system is the most common failure point. Pneumatic wipers vs. electric mechanical wipers have different reliability profiles. Engineer reviews should focus on the wiper ring material compatibility with the quartz sleeve.

Lifecycle Cost Drivers

The CAPEX difference between Ozonia and Evoqua is often negligible compared to the 20-year OPEX.

- Energy Consumption: This is the largest driver. Ozone generation efficiency (kWh/kg Ozone) varies based on concentration. UV efficiency is measured in Watts/UV output.

- Consumables:

- UV: Lamp life (12,000 to 16,000 hours), quartz sleeves, and wiper seals.

- Ozone: Dielectric replacement (typically every 10-15 years, but expensive), LOX consumption, and cooling water costs.

Detailed Comparison Data

The following tables provide a direct comparison to assist engineers in the Ozonia vs Evoqua Disinfection Equipment: Comparison & Best Fit decision matrix. Note that “Evoqua” encompasses legacy Wallace & Tiernan, Pacific Ozone, and ATG UV product lines, while “Ozonia” represents the core Veolia ozone/UV portfolio.

Table 1: Technology & Portfolio Comparison

| Feature / Criteria | Ozonia (Veolia) | Evoqua (Xylem) |

|---|---|---|

| Primary Technology Focus | High-capacity Ozone Generation and Large-Scale UV Systems. Known for heavy industrial and large municipal infrastructure. | Extremely broad portfolio. Includes Gas Chlorination (W&T), Modular Ozone (Pacific), Polymer/UV (ATG), and On-site Generation (OSG). |

| Ozone Generation Tech | IGBT Technology: Intelligent Gap Protection (IGP). Optimized for high concentration (10-14% wt). Dielectrics are typically ceramic/glass hybrid. | Mixed Portfolio: Ranges from smaller air-cooled units (Pacific Ozone heritage) to larger water-cooled systems. Focus on modularity and skid integration. |

| UV Disinfection Tech | Aquaray Series: Strong in vertical lamp arrangements for open channels and high-performance LPHO/Amalgam systems. | ATG / ETS Legacy: Strong in Medium Pressure (MP) systems for aquatics and wastewater, and closed vessel UV. |

| Control Integration | Proprietary “SmartO3” or similar controllers. High level of diagnostics. Often requires strict adherence to their PLC standards. | Wallace & Tiernan controllers are the industry standard for chemical feed. Excellent integration of analyzers and dosing control loops. |

| Best Fit Application | Large Municipal WTP/WWTP (>50 MGD), Micropollutant removal, Pulp & Paper bleaching. | Small to Mid-sized Muni, Retrofits requiring skid-mounts, Chlorination/Dechlorination projects, Aquatics. |

Table 2: Application Fit Matrix

| Application Scenario | Preferred Approach | Key Engineering Considerations |

|---|---|---|

| Large Municipal Wastewater (Disinfection) | Competitive Split | Ozonia excels in vertical rack UV for open channels. Evoqua (via ATG/ETS) is strong in closed vessel MP UV where footprint is tight. |

| Potable Water (Taste & Odor / AOP) | Ozonia (Veolia) | High-concentration ozone generation is critical here to minimize bromate formation and maximize transfer efficiency. Ozonia’s large-scale generators are standard. |

| Small/Mid Industrial Skid | Evoqua (Pacific Ozone) | Evoqua’s pre-engineered ozone skids are “plug and play.” Ozonia units are often too custom/complex for simple industrial loops. |

| Gas Chlorination / Dechlorination | Evoqua (Wallace & Tiernan) | While Ozonia focuses on Ozone/UV, Evoqua owns the W&T brand, which is the undisputed standard for vacuum gas chlorination (V-Notch technology). |

| Wastewater Reuse (Title 22) | Ozonia or Evoqua | Both have validated systems (NWRI validation). Selection often comes down to lifecycle cost analysis of lamp replacement and power draw. |

Engineer & Operator Field Notes

Specifications on paper often differ from reality in the field. The following notes are compiled from commissioning experiences and long-term operational feedback regarding Ozonia vs Evoqua Disinfection Equipment: Comparison & Best Fit.

Commissioning & Acceptance Testing

Commissioning ozone and UV equipment requires specialized protocols.

- Ozone Leak Tests: Never rely solely on ambient monitors during commissioning. Use handheld spot checkers at all flange connections. Ozonia’s vessels are robust, but transport vibration can loosen internal dielectric connections.

- Harmonic Distortion: Both manufacturers use Variable Frequency Drives (VFDs) or complex power supply units (PSUs) to regulate output. This creates Total Harmonic Distortion (THD) on the electrical bus.

Field Note: Ensure the specification requires an IEEE 519 compliance study. Active harmonic filters are often required for large Ozonia or Evoqua installations to prevent frying other sensitive electronics in the plant. - UV Intensity Verification: During Site Acceptance Testing (SAT), verify the UV intensity sensors against a reference sensor. Sensor drift is a common issue with Evoqua and Ozonia systems if not calibrated correctly initially.

Common Specification Mistakes

Engineers often copy specs from 5-year-old projects. Do not specify “Ozonia” or “Wallace & Tiernan” alone. Specify the performance requirement and list acceptable manufacturers including their current parent companies (Veolia/Xylem). Old model numbers (e.g., Ozonia CFS series) may be obsolete, leading to costly change orders during submittals.

- Under-specifying Cooling Water: Ozone generators are water-cooled. If the plant service water (W2 or W3) has high hardness or chlorides, the generator heat exchangers will scale or corrode. Specify a closed-loop chiller system if plant water quality is suspect.

- Ignoring “System Responsibility”: A common error is splitting the ozone generator supply from the ozone destruct unit supply. The generator manufacturer must be responsible for the destruct unit to ensure safety interlocks function correctly.

O&M Burden & Strategy

Ozonia (Veolia):

Maintenance teams report that Ozonia’s dielectrics are durable but difficult to access in older models. Newer designs have improved access. The primary O&M burden is the cooling water system and the Power Supply Unit (PSU) air filters. If filters clog, IGBTs overheat and fail.

Evoqua (Xylem/W&T/ATG):

For their UV systems, the wiping mechanism is the main maintenance item. Operators must check wiper seals monthly. For W&T chlorinators, injector cleaning and diaphragm replacement are routine. Evoqua’s ozone skids are generally accessible but require strict adherence to desiccant dryer maintenance if not using LOX.

Design Details and Calculations

Sizing Logic: Ozone

Sizing an ozone system revolves around the CT Value (Concentration × Time).

Calculation: $$ CT = C_{residual} times T_{10} $$

Where $C_{residual}$ is the dissolved ozone concentration (mg/L) at the outlet, and $T_{10}$ is the time for 10% of the water to pass through the contactor.

Sizing Step:

- Determine the Ozone Demand of the water (TOC, Nitrite, Iron/Manganese demand).

- Add the required Decay Demand.

- Calculate required Applied Dose.

- Convert Dose (mg/L) and Flow (MGD) to lbs/day or kg/hr.

- Selection Point: Select a generator where the required output is at 80% of maximum capacity to allow for aging and fouling.

Sizing Logic: UV

UV sizing is based on Bioassay Validation rather than theoretical calculation alone.

Key Formula: $$ Dose = Intensity times Time $$

However, engineers must specify the End of Lamp Life (EOLL) factor (typically 0.8 to 0.9) and the Fouling Factor (typically 0.8 to 0.95 depending on the cleaning system).

When comparing Ozonia vs Evoqua UV:

- Check the validated range. If your flow requires 40 mJ/cm², ensure the reactor is validated for that dose at the specific UVT of your water.

- Verify Head Loss calculations at Peak Wet Weather Flow (PWWF).

Standards & Compliance

- AWWA B304: Standard for Liquid Oxygen for Ozone Generation.

- NWRI Guidelines: The bible for water reuse UV sizing (National Water Research Institute).

- UL 508A: Mandatory for control panels.

- NFPA 820: Fire protection standard for wastewater treatment plants (critical for ozone destruct units located in classified areas).

Frequently Asked Questions

What is the main difference between Ozonia and Evoqua ozone generators?

The primary difference lies in the dielectric technology and market focus. Ozonia (Veolia) typically uses proprietary glass/ceramic dielectrics optimized for very large-scale, high-concentration (12%+) applications typical of large water treatment plants. Evoqua (Xylem) offers a broader range of technologies, including modular, skid-mounted units (legacy Pacific Ozone) that are often better suited for industrial applications or smaller municipal retrofits, alongside their larger legacy systems.

How does maintenance cost compare between the two manufacturers?

Maintenance costs are generally comparable but concentrated in different areas. Ozonia systems may have higher individual part costs (proprietary dielectrics and IGBT cards) but potentially longer intervals between major overhauls. Evoqua’s UV systems (ATG/ETS) rely heavily on wiper maintenance and seal replacements. For ozone, both require strict maintenance of the cooling water system to prevent expensive vessel failures.

Can I integrate an Evoqua controller with an existing Ozonia SCADA system?

Yes, but it requires careful specification of communication protocols. Both manufacturers support Ethernet/IP, Modbus TCP/IP, and Profinet. The challenge is not the protocol but the data mapping. You must specify a “Unified Tag List” in the design phase to ensure the Evoqua controller exposes the necessary alarms and status words to the SCADA system in a format that matches the plant’s standards.

Which manufacturer is better for wastewater UV disinfection?

It depends on the channel configuration and effluent quality. For open channel systems in large plants, Ozonia’s Aquaray vertical lamp systems are highly regarded for ease of access (changing lamps without removing racks). For closed vessel applications (pipe runs), Evoqua’s ATG/ETS Medium Pressure systems offer high power density, which is excellent for footprint-constrained plants, though energy costs may be higher than Low Pressure High Output (LPHO) alternatives.

What is the typical lifespan of ozone dielectrics?

With proper cooling water quality and air preparation (dew point < -60°F), ozone dielectrics should last 10 to 15 years. However, thermal shock (rapid changes in cooling water temp) or moisture in the feed gas can cause dielectric failure in minutes. This vulnerability exists in both Ozonia and Evoqua equipment, emphasizing the need for robust ancillary system design.

Why is “Harmonic Mitigation” critical when specifying these units?

Both Ozone PSUs and UV Ballasts are non-linear electrical loads. They draw current in pulses, creating harmonics that can distort the voltage waveform across the plant’s power grid. Without Active Harmonic Filters (AHF) or 18-pulse drives, this distortion can cause overheating in transformers and nuisance tripping of other sensitive equipment. Always specify IEEE 519 compliance at the Point of Common Coupling (PCC).

Conclusion

Key Takeaways: Engineering Selection Summary

- Consolidation Matters: Remember that Ozonia is now Veolia and Evoqua is now Xylem. Support structures and parts supply chains have merged.

- Ozone Strength: Ozonia generally holds the edge for massive, custom-built infrastructure projects requiring high-concentration ozone.

- System Breadth: Evoqua (Xylem) offers a wider “total disinfection” portfolio, including superior gas chlorination (W&T) and modular ozone/UV skids.

- Total Cost of Ownership: Energy consumption dominates the lifecycle cost. A 2% difference in generator efficiency outperforms a 10% savings in initial capital cost.

- Cooling is Critical: 80% of ozone generator failures are traced to poor cooling water or feed gas preparation, not the generator brand itself.

The decision in the Ozonia vs Evoqua Disinfection Equipment: Comparison & Best Fit analysis is rarely about which brand is objectively “better,” but rather which platform aligns with the specific constraints of the project. For large-scale municipal infrastructure where footprint is available and operator expertise is high, Ozonia’s high-efficiency ozone generators are a formidable standard. Conversely, for projects requiring modularity, tight integration of diverse disinfection technologies (like UV + Chlorine), or retrofit capabilities, the Evoqua (Xylem) portfolio often provides superior flexibility.

Engineers should focus their specifications on performance metrics—Specific Energy Consumption (kWh/lb Ozone), UVT validation ranges, and strict material compatibility—rather than brand loyalty. By forcing a rigorous technical comparison of the sub-systems (dielectrics, wipers, ballasts), utilities can ensure they purchase a system that provides reliable disinfection for the next 20 years, regardless of the logo on the nameplate.