Preventing and Managing Pump Cavitation in Water Treatment Systems

Preventing and Managing Pump Cavitation in Water Treatment Systems

Introduction

Welcome to the wild world of cavitation pumps, where water treatment meets the drama of physics! If you’ve ever wondered why your pump sounds like a rock concert or why it seems to be losing its mojo, you might be dealing with the notorious villain known as cavitation.

Cavitation is not just a fancy word thrown around in engineering circles; it’s a real headache for municipalities and wastewater treatment operators. Understanding pump cavitation is crucial because it can lead to significant damage, inefficiencies, and even costly repairs. Think of it as the water treatment equivalent of a bad hair day if you don’t address it quickly, things can spiral out of control!

But fear not! In this guide, we will unravel the mysteries of pump cavitation from its causes and effects to prevention techniques that will keep your systems running smoother than a fresh jar of peanut butter. Whether you’re an engineer looking for solutions or an operator trying to troubleshoot issues, we’ve got you covered.

So grab your hard hat and let’s dive into the depths of pump cavitation because when it comes to keeping those pumps humming along happily, knowledge is power!

Understanding Pump Cavitation

So, what exactly is cavitation in pumps? Imagine a party where everyone is having a great time, but suddenly someone starts to scream. The music stops, and chaos ensues. That’s a bit like what happens in a pump when cavitation strikes. In simple terms, cavitation occurs when the pressure in a pump drops below the vapor pressure of the liquid being pumped, leading to the formation of vapor bubbles. These bubbles can collapse violently, creating shockwaves that can wreak havoc on your pump.

Understanding the mechanism of cavitation formation is crucial for anyone involved in water treatment systems. It typically begins when there’s an insufficient amount of liquid entering the pump or when there’s too much suction pressure drop. Think of it like trying to drink a thick milkshake through a straw; if you suck too hard (or fast), you might just get air instead of that delicious shake!

Key Takeaway: Recognizing the signs and symptoms of cavitation early can save you from costly repairs and downtime.

The importance of understanding pump cavitation cannot be overstated. Not only does it help in diagnosing issues early like detecting pump cavitation before it spirals out of control but it also plays a significant role in pump design and maintenance. By grasping how cavitation develops, engineers can make informed decisions to prevent it from occurring in the first place.

In essence, understanding pump cavitation is like having an advanced warning system for your pumps. With this knowledge, you can implement effective strategies for pump cavitation prevention, ensuring your water treatment systems run smoothly and efficiently.

Causes of Pump Cavitation

Understanding the causes of pump cavitation is like being a detective in a mystery novel. You need to piece together various clues to avoid the disastrous consequences that come with this pesky phenomenon. Let’s dive into the main culprits that lead to cavitation in pumps.

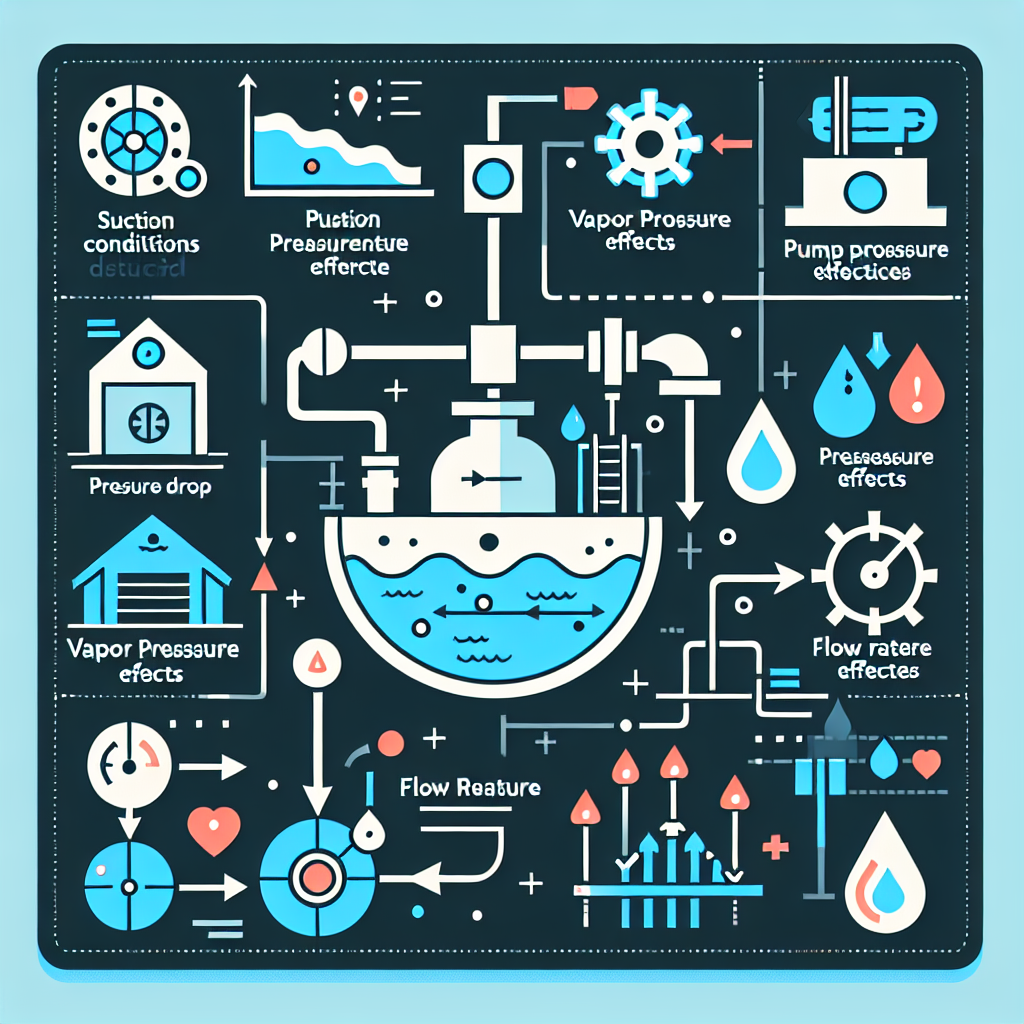

- Suction Conditions Affecting Pump Cavitation: The first suspect is often the suction side of your system. If the suction conditions are less than ideal think low pressure or high elevation you may be setting the stage for cavitation chaos. Insufficient liquid supply can lead to vapor bubbles forming, which can wreak havoc when they collapse.

- Pressure Drop and Its Connection to Cavitation: Next up, we have pressure drop. Imagine a roller coaster plummeting down a steep hill; that’s what happens when there’s a significant drop in pressure within your system. This sudden decrease can lower the pressure below the vapor pressure of the liquid, leading to cavitation. Maintaining optimal flow conditions is crucial!

- Vapor Pressure Role in Pump Cavitation: Speaking of vapor pressure, it plays a pivotal role in this whole drama. Each liquid has its own vapor pressure at different temperatures, and when your operating conditions dip below this threshold, you’re inviting trouble. It’s like inviting a vampire into your home you’ll regret it!

- Flow Rate and Pump Cavitation Relationship: Finally, let’s chat about flow rate. Too high or too low can lead you down the path of pump cavitation. A high flow rate can create turbulence that disrupts smooth operation, while too low might not provide enough energy to keep things flowing smoothly both scenarios can lead to those dreaded vapor bubbles.

Key Takeaway: To minimize pump cavitation risk, ensure optimal suction conditions, manage pressure drops effectively, understand vapor pressures at play, and maintain appropriate flow rates!

Signs and Symptoms of Pump Cavitation

Recognizing the signs and symptoms of pump cavitation is crucial for maintaining the health of your cavitation pumps. Ignoring these indicators can lead to costly repairs and downtime. Here’s what to look out for:

- Noise and Vibration Indicators: If your pump starts sounding like a rock concert with an offbeat drummer, it’s time to pay attention. Unusual noises such as grinding, knocking, or a distinct rattling sound can indicate cavitation at work. These noises are typically caused by vapor bubbles collapsing within the pump.

- Performance Degradation Signs: Is your pump not pumping like it used to? A noticeable drop in flow rate or pressure can signal that cavitation is wreaking havoc on performance. This degradation often results from the hydraulic inefficiencies caused by cavitating bubbles.

- Visual Inspection for Damage: Inspecting your pump regularly can reveal telltale signs of cavitation damage. Look for pitting or erosion on impellers and casing, particularly around the inlet area where cavitation is most likely to occur. Mechanical seal damage from cavitation can also be a red flag if seals are wearing out faster than expected, this could be a symptom of underlying issues.

Key Takeaway: Detecting pump cavitation early can save you from extensive repairs. Regular inspections and monitoring for noise and performance changes are essential in avoiding serious issues.

The Effects of Cavitation on Pumps

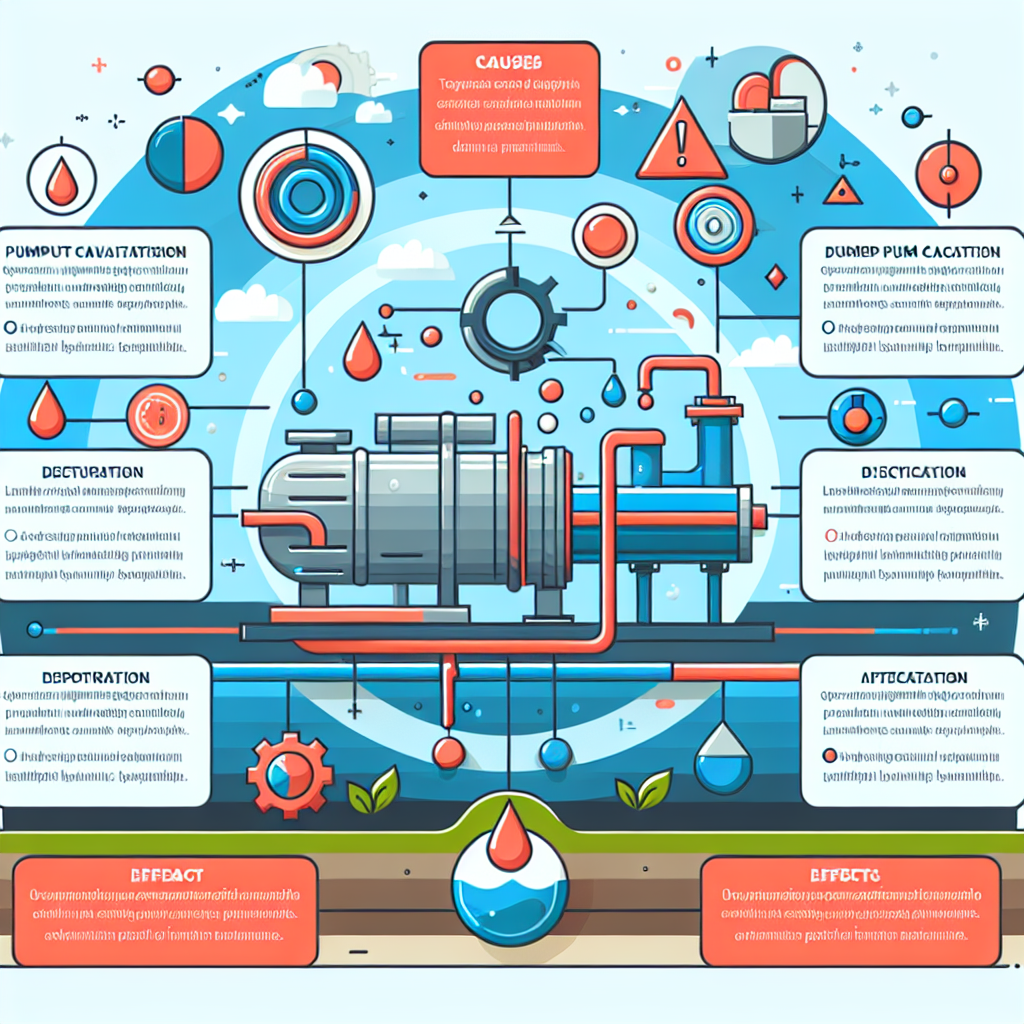

Cavitation is not just a buzzword thrown around in engineering circles; it’s a serious concern for anyone dealing with cavitation pumps. Understanding the effects of cavitation on pumps is crucial for maintaining efficiency and longevity in water treatment systems.

-

Cavitation Damage in Pumps: Types and Severity

Cavitation can wreak havoc on your pumps, leading to various types of damage:

- Erosion: High-velocity bubbles collapse near the pump surfaces, leading to material loss. Think of it as tiny explosions that slowly eat away at metal.

- Vibration: The turbulence caused by cavitation can lead to excessive vibration, which not only affects performance but can also loosen fittings and cause mechanical failures.

- Noise: If your pump sounds like it’s auditioning for a horror movie, you might be dealing with cavitation. This noise is often described as a gravel-like sound, indicating that things are not running smoothly.

-

Impact of Cavitation on Pump Performance and Efficiency

The presence of cavitation can significantly reduce the efficiency of your pump. When bubbles form and collapse, they disrupt the flow of fluid, leading to:

- Reduced Flow Rate: As cavitation interrupts the smooth operation, you may notice a drop in the flow rate. It’s like trying to drink through a straw that keeps collapsing!

- Poor Pressure Delivery: Inconsistent pressure output can throw off downstream processes, making it harder for your system to operate effectively.

- Increased Energy Consumption: More energy is required to compensate for the inefficiencies caused by cavitation, resulting in higher operational costs.

-

Long-Term Consequences of Unchecked Cavitation Issues

If left unaddressed, cavitation can lead to severe long-term consequences:

- Pump Failure: Eventually, all this wear and tear adds up. A pump that could have lasted years may fail prematurely due to cavitation damage.

- Increased Maintenance Costs: More frequent repairs mean more downtime and higher costs. It’s like paying for a gym membership but never going money down the drain!

- Total System Disruption: A failing pump can lead to broader system failures within water treatment plants, affecting everything from water quality to compliance with regulations.

Takeaway: Understanding the effects of cavitation on pumps is essential for effective management. Early detection and proactive measures are key to avoiding costly repairs and maintaining optimal performance.

Cavitation Prevention Techniques for Pumps

Preventing cavitation in pumps is like keeping your favorite ice cream from melting on a hot day timely action can save you from a sticky situation. Let’s dive into some effective techniques to keep your cavitation pumps running smoothly!

NPSH (Net Positive Suction Head) Considerations

The NPSH is your pump’s best friend when it comes to avoiding cavitation. Ensuring that the available NPSH exceeds the required NPSH is crucial. This means:

- Calculating the NPSH accurately based on system conditions.

- Regularly monitoring and adjusting suction conditions to maintain optimal levels.

- Considering elevation changes that could impact pressure.

Pump Design Considerations to Avoid Cavitation Issues

A well-designed pump is like a well-tailored suit it fits perfectly and performs flawlessly. Here are some design considerations:

- Impeller Design: Opt for an impeller with a larger diameter or multiple stages to reduce velocity and minimize cavitation risk.

- Volute Design: A properly designed volute can help manage flow rates and reduce turbulence, which are key in preventing cavitation.

- Material Selection: Use materials resistant to cavitation damage, especially if your pumps will be handling abrasive or corrosive fluids.

Pump Maintenance for Cavitation Avoidance Strategies

An ounce of prevention is worth a pound of cure, especially when it comes to pump maintenance. Here are some strategies to keep in mind:

- Regular Inspections: Keep an eye out for signs of wear and tear, such as vibrations or unusual noises that could indicate developing cavitation issues.

- Lubrication Checks: Ensure all moving parts are adequately lubricated; dry components can exacerbate cavitation effects.

- Suction Strainer Maintenance: Clean or replace suction strainers regularly to prevent blockages that could lead to pressure drops and subsequent cavitation risks.

Remember: Early detection is key! Detecting pump cavitation early can save you from costly repairs and downtime. Make sure your team is trained to recognize the early signs!

Troubleshooting Pump Cavitation Issues

So, you’ve spotted the signs of pump cavitation, and now it’s time to roll up your sleeves and dive into some troubleshooting. Think of it as being a detective in the world of water treatment systems. Let’s break down how to diagnose and tackle those pesky cavitation issues that can wreak havoc on your cavitation pumps.

Diagnosing Pump Cavitation: Methods and Tools

First things first: you need to identify whether cavitation is indeed the culprit behind your pump’s woes. Here are some methods that will help you get to the bottom of it:

- Vibration Analysis: Use a vibration analyzer to detect unusual vibrations that could indicate cavitation.

- Noise Monitoring: Listen for that distinct “gravel” or “marbles” sound, which is essentially your pump screaming for help.

- Pressure Measurement: Monitor inlet pressure closely and compare it with the required NPSH (Net Positive Suction Head) for your specific pump model.

Cavitation Testing in Pump Laboratories

If you’re still scratching your head, consider sending a sample of your pump to a specialized laboratory for cavitation testing. These facilities can simulate various operating conditions to pinpoint the exact cause of cavitation. They’ll look at factors like:

- Hydraulic conditions: They will analyze how flow rates and pressures interact within your system.

- Material integrity: Assessing any potential damage from repeated cavitation events.

- Pump design flaws: Identifying if design aspects are contributing to cavitation.

Cavitation Simulation in Pump Design

If you’re in the design phase or considering upgrades, utilizing simulation software can be a game-changer. This technology allows engineers to visualize how changes in design will impact performance under various conditions, including:

- Flow dynamics: Understanding how fluid moves through different geometries.

- Cavitating conditions: Predicting when and where cavitation might occur based on operational scenarios.

- Material selection: Choosing materials that can withstand potential cavitation damage.

Key Takeaway: Early detection is crucial! Regular monitoring and employing advanced testing methods can save you from costly repairs down the line. Make sure to have a solid maintenance plan in place!

Cavitation Control Methods and Solutions for Pumps

When it comes to cavitation pumps, a proactive approach can save you from a world of hurt both financially and operationally. Think of cavitation as the villain in your pump’s superhero story; understanding how to control it is your secret weapon. Let’s dive into some effective methods and solutions to keep those pesky bubbles at bay!

-

Pump Protection from Cavitation Damage Techniques

First things first, let’s talk about protection. Just like you wouldn’t let your favorite vintage car drive through a hailstorm without cover, your pumps need safeguarding too! Here are some techniques:

- Installation of Anti-Cavitation Devices: Devices such as vortex plates or diffusers can help manage flow patterns and reduce the likelihood of cavitation.

- Use of Variable Frequency Drives (VFDs): These allow for precise control over pump speed, adjusting flow rates dynamically to maintain optimal suction conditions.

- Proper Sizing: Ensure that the pump is appropriately sized for its application. Oversized pumps can lead to excessive flow rates, increasing cavitation risks.

-

Cavitation Reduction Through Operational Adjustments

Sometimes, all it takes is a little tweaking! Operational adjustments can make a big difference in reducing pump cavitation:

- Monitoring NPSH Available (NPSHa): Always ensure that your NPSHa exceeds the NPSH Required (NPSHr) by a comfortable margin to prevent cavitation.

- Avoiding Sudden Flow Changes: Implement gradual changes in flow rates rather than abrupt shifts which can create pressure drops conducive to cavitation.

- Regular Maintenance Checks: Schedule routine inspections and maintenance to detect any signs of wear or damage that could exacerbate cavitation issues.

-

Evolving Technologies for Minimizing Pump Cavitation Risk

The world of pump technology is ever-evolving, and staying on top of new innovations can be your best defense against cavitation:

- Cavitating Flow Simulation Software: Invest in advanced software that simulates fluid dynamics within your system, helping you identify potential cavitation zones before they become problematic.

- Smart Sensors and IoT Technology: Utilize smart sensors that monitor pressure and vibration in real-time, allowing for immediate adjustments when signs of pump cavitation are detected.

- Cavitating Pump Designs: Explore newly designed pumps specifically engineered to handle higher levels of cavitation without damage.

Takeaway: Effective management of pump cavitation not only prolongs the life of your equipment but also enhances overall system efficiency. Stay ahead with proactive maintenance, operational adjustments, and embracing new technologies!

Conclusion

So, there you have it! Understanding and managing cavitation in pumps is not just a technical necessity; it’s a vital part of ensuring your water treatment systems run smoothly and efficiently. By grasping the causes of pump cavitation, recognizing its signs, and implementing effective prevention techniques, you can save yourself from costly repairs and downtime.

The ripple effects of cavitation can be damaging literally! From mechanical seal damage to performance degradation, the impacts are far-reaching. But fear not! With the right strategies in place like monitoring your NPSH and adjusting operational parameters you can significantly reduce the risk of cavitation.

Key Takeaways:

- Regularly assess suction conditions to prevent pump cavitation.

- Conduct routine maintenance to catch symptoms early.

- Utilize advanced technologies for real-time monitoring of cavitation risks.

Remember, diagnosing pump cavitation isn’t just about fixing problems; it’s about creating a proactive culture around your equipment. Equip yourself with knowledge and tools to tackle this issue head-on. After all, when it comes to managing cavitation pumps, an ounce of prevention is worth a pound of cure!

Ready to dive deeper into pump management? Explore our resources or reach out for expert advice tailored to your specific needs!

article blockquote,article ol li,article p,article ul li{font-family:inherit;font-size:18px}.featuredimage{height:300px;overflow:hidden;position:relative;margin-top:20px;margin-bottom:20px}.featuredimage img{width:100%;height:100%;top:50%;left:50%;object-fit:cover;position:absolute;transform:translate(-50%,-50%)}article p{line-height:30px}article ol li,article ul li{line-height:30px;margin-bottom:15px}article blockquote{border-left:4px solid #ccc;font-style:italic;background-color:#f8f9fa;padding:20px;border-radius:5px;margin:15px 10px}article div.info-box{background-color:#fff9db;padding:20px;border-radius:5px;margin:15px 0;border:1px solid #efe496}article table{margin:15px 0;padding:10px;border:1px solid #ccc}article div.info-box p{margin-bottom:0;margin-top:0}article span.highlight{background-color:#f8f9fb;padding:2px 5px;border-radius:5px}article div.info-box span.highlight{background:0 0!important;padding:0;border-radius:0}article img{max-width:100%;margin:20px 0}