Top 10 Grinder Pump Manufacturers for Water and Wastewater

Introduction

For municipal engineers and utility directors, the proliferation of “flushable” wipes and increasing solids loading in wastewater streams has transformed the specification of pump stations. The days of standard solids-handling pumps working universally are over; difficult terrain and high-head requirements often necessitate Low Pressure Sewer (LPS) systems driven by robust grinder pumps. However, selecting the right equipment from the Top 10 Grinder Pump Manufacturers for Water and Wastewater is not merely a matter of brand preference—it is an exercise in matching hydraulic characteristics and cutting technology to specific site constraints.

A surprising statistic in the industry suggests that over 60% of premature grinder pump failures are due to misapplication—specifically, using centrifugal grinders where progressive cavity (PC) units are required, or vice versa, leading to operation off the best efficiency point (BEP) or thermal overload. Furthermore, the operational expenditure (OPEX) related to unclogging pumps has risen dramatically, making the “cutter hardness” and “torque” specifications more critical than initial capital cost.

Grinder pumps are typically utilized in two distinct environments: residential/commercial pressure sewer systems where gravity flow is cost-prohibitive, and in plant-internal applications for homogenizing sludge or handling screening debris. This article serves as a technical guide for engineers to navigate the Top 10 Grinder Pump Manufacturers for Water and Wastewater, ensuring that specifications lead to reliable, long-term infrastructure rather than chronic maintenance headaches.

How to Select / Specify

When evaluating the Top 10 Grinder Pump Manufacturers for Water and Wastewater, the specification process must move beyond simple flow and head requirements. Engineers must distinguish between the two primary technologies: Semi-Positive Displacement (SPD/Progressive Cavity) and Centrifugal. The selection criteria below provide the framework for a defensible, engineering-grade specification.

Duty Conditions & Operating Envelope

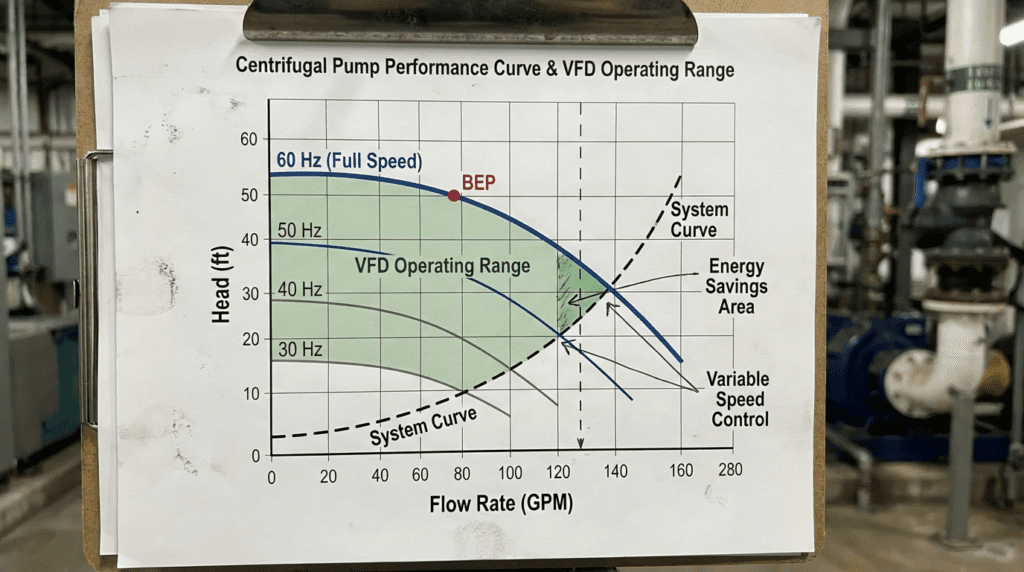

The operating envelope is the first filter in the selection process. Engineers must analyze the system curve against the pump curve, but with grinder pumps, the technology dictates the curve shape.

- Flow Stability vs. Head Variation: Progressive Cavity (PC) pumps utilize a rotor and stator to produce a near-vertical pump curve. This means flow remains relatively constant regardless of system pressure (head). This is ideal for large LPS networks where friction losses vary wildly as other pumps cycle on and off.

- Centrifugal Grinders: These operate like standard wastewater pumps with a steep efficiency curve. They provide higher flows at lower heads but suffer significant flow reduction as system pressure increases. They are typically better suited for lift stations pumping to a gravity manhole short distances away.

- Intermittent vs. Continuous Duty: Most 2HP residential grinders are rated for intermittent duty (e.g., 15 minutes on, 45 off). For commercial applications or lift stations, specifications must demand continuous duty ratings (S1) to prevent stator burn-out or motor overheating.

Materials & Compatibility

The longevity of a grinder pump is directly tied to the metallurgy of the cutting mechanism and the pump housing.

- Cutter Hardness: The industry standard for high-quality shredding rings and cutters is 440C Stainless Steel hardened to a minimum of Rockwell C 55-60. Specifications should explicitly reject carbon steel cutters or hardness ratings below 50 HRC, as these will dull rapidly against grit, leading to ragging.

- Corrosion Resistance: In septic tank effluent pumping (STEP) or grinder vaults, H2S concentrations can be high. Cast iron housings (ASTM A48 Class 30) are standard, but epoxy coatings are critical. For industrial applications with aggressive chemical streams, 316 Stainless Steel fitted pumps may be required.

- Stator Materials (PC Pumps): The elastomeric stator in PC pumps must be compatible with the wastewater temperature and chemistry. Standard Buna-N is typical, but high-temperature effluents may require Viton.

Hydraulics & Process Performance

Unlike standard non-clog pumps, efficiency is often secondary to torque and cutting ability in grinder pump selection. However, hydraulic integration remains vital.

- Scouring Velocity: The pump must generate sufficient flow to maintain a minimum of 2 feet per second (fps) scouring velocity in the force main to prevent solids deposition. PC pumps often have lower flows (e.g., 10-15 GPM), necessitating smaller diameter discharge piping (1.25″ to 2″) to achieve this velocity.

- NPSH and Submergence: While grinders are submersible, minimum submergence is critical to prevent vortexing and ensure motor cooling. Specifications must define the “pump off” level to ensure the volute or stator remains submerged.

Installation Environment & Constructability

The physical constraints of the installation site often dictate the manufacturer choice.

- Guide Rail Systems: For stations deeper than 5 feet, a stainless steel guide rail system (dual rail preferred for stability) is mandatory for safe removal. Threaded discharge connections requiring personnel entry should be prohibited in modern specs.

- Retrofit Capabilities: Several manufacturers offer “drop-in” cores designed to fit into competitors’ existing basins. This is a critical consideration for utilities managing aging LPS assets.

- Basin Geometry: Fiberglass (FRP) or HDPE basins must be sized to prevent “short cycling” of the pump. A common specification error is undersizing the basin, leading to motor starts exceeding the NEMA allowable starts per hour (typically 10-12 starts/hour max).

Reliability, Redundancy & Failure Modes

Engineers must design for the inevitable jam or component failure.

- Jam Recovery: Some advanced grinder controllers offer a “reversing” feature. If the pump detects a high-amp jam, it reverses rotation to clear the obstruction, then retries. This feature significantly reduces operator call-outs.

- Seal Redundancy: Specify dual mechanical seals with a moisture sensing probe in the oil chamber. This provides an early warning of the primary seal failure before the motor is compromised.

- Thermal Protection: Motors must have embedded thermal switches that automatically cut power upon overheating and reset after cooling.

Lifecycle Cost Drivers

The total cost of ownership (TCO) for grinder pumps is heavily skewed toward maintenance rather than energy.

- Stator Replacement (PC Pumps): PC pumps wear linearly. The stator will eventually wear out, especially if grit is present. The cost and ease of stator replacement should be evaluated.

- Cutter Cartridge Replacement: Integrated cutter cartridges that can be swapped as a single unit reduce field maintenance time compared to shimming and adjusting individual blades.

- Energy Consumption: While PC pumps generally draw lower amps, they may run longer to evacuate a basin due to lower flow rates. Centrifugal pumps draw higher amps for shorter durations. The net energy usage is often comparable, but demand charges may differ.

Comparison Tables

The following tables provide a structured comparison to assist engineers in developing “Approved Manufacturers” lists and selecting the correct technology. Table 1 focuses on the market positioning of the major OEMs, while Table 2 assists in the technological decision between Centrifugal and Progressive Cavity designs.

| Manufacturer | Primary Technology Focus | Typical Applications | Key Engineering Strengths | Limitations / Considerations |

|---|---|---|---|---|

| E/One (Environment One) | Progressive Cavity (SPD) | Regional LPS Systems, High Head Terrain | Dominant market leader in PC technology; constant flow regardless of head; complete station packages. | Lower flow rates (typ. 10-15 GPM); stators sensitive to run-dry events. |

| Xylem (Flygt) | Centrifugal | Municipal Lift Stations, Commercial | “N-Technology” self-cleaning impellers; high reliability; robust monitoring relays (MiniCAS). | Premium pricing; typically geared toward larger commercial/municipal stations rather than single homes. |

| Liberty Pumps | Centrifugal & PC | Residential, Light Commercial | “V-Slice” cutter technology; excellent availability; omnivore series combines high head with centrifugal ruggedness. | Primarily focused on fractional to 2HP range; less presence in large municipal master-lift stations. |

| Zoeller Engineered Products | Centrifugal & PC | Residential, Hazardous Locations | “Tri-Slice” cutter system; heavy-duty cast iron construction; reversible cutter action models available. | Conservative pump curves; heavy weight requires sturdy retrieval systems. |

| Sulzer (ABS) | Centrifugal | Municipal, Industrial | Piranha series offers exceptional shredding; adjustable bottom plates to maintain efficiency. | Maintenance requires specialized tools; parts availability varies by region. |

| Pentair Myers | Centrifugal & PC | Municipal LPS, Retrofits | Versatile product line; dual seal options standard on municipal specs; robust lift-out rail systems. | Wide product range can make specific model selection complex without rep guidance. |

| Crane Pumps (Barnes) | Centrifugal (Slicer) | Residential, Commercial | Blade XGV and OmniGrind series; focuses on “slicing” rather than just grinding to prevent roping. | Specific focus on retrofit markets; hydraulic curves favor medium heads. |

| Hydromatic (Pentair) | Centrifugal | Municipal, Residential | Two-stage grinding mechanism; capacitor start/run options for single phase; legacy reliability. | Older designs are heavy; overlapping portfolio with Myers (both Pentair brands). |

| Franklin Electric (Little Giant) | Centrifugal | Residential, Light Commercial | Patent-pending cutter designs; higher head centrifugal options (GP series). cost-effective. | Typically viewed as residential/light commercial grade rather than heavy industrial municipal spec. |

| Wilo | Centrifugal | Municipal, Commercial | High-efficiency motors; innovative cutter geometries; strong presence in European-style pressure networks. | US market penetration is regional; control interfaces may differ from NEMA standards. |

| Feature / Scenario | Centrifugal Grinder | Progressive Cavity (PC) Grinder | Engineering Implication |

|---|---|---|---|

| Head (Pressure) Capacity | Low to Medium (typ. < 100-140 ft TDH) | High to Very High (typ. > 200 ft TDH) | Use PC for long distances or elevation changes. Use Centrifugal for short, high-volume lifts. |

| Flow Characteristics | Variable (Dependent on system pressure) | Constant (Independent of system pressure) | PC allows for predictable scouring velocity in extensive networks where pressure fluctuates. |

| Solids Handling | High velocity chopping | Macerating and positive displacement | Centrifugal can handle slightly larger/harder objects without jamming; PC stators can be damaged by sharp grit/glass. |

| Wear Components | Impeller and Cutter Plate | Rotor and Stator | PC stators are a “consumable” wear item (3-7 years). Centrifugal wear is generally longer term but efficiency drops. |

| Dry Run Capability | Limited (Seal damage risk) | Zero (Stator will burn immediately) | PC pumps strictly require redundant level controls to prevent dry running. |

Engineer & Operator Field Notes

Successful implementation of equipment from the Top 10 Grinder Pump Manufacturers for Water and Wastewater depends heavily on field execution. The following notes are compiled from commissioning reports and operator logs.

Commissioning & Acceptance Testing

The Site Acceptance Test (SAT) is the final gate before ownership transfer. For grinder pumps, specific checks are required:

- Rotation Check: This is the most critical step. Running a grinder pump in reverse reduces capacity and, for threaded impellers, can unscrew the impeller, destroying the housing. Pro Tip: Do not rely on arrow markings alone; observe the “kick” of the pump on startup (it kicks opposite to rotation) or observe flow.

- Amp Draw Baseline: Record amperage on all three legs (for 3-phase) or start/run windings (1-phase) while pumping liquid. This establishes the baseline for future troubleshooting. An empty tank test is insufficient; the pump must be under load.

- Shut-off Head Test: Close the discharge valve momentarily to verify the pump produces the rated shut-off head. This confirms the hydraulics are intact and the wear rings/stator are tight.

Common Specification Mistakes

Consulting engineers often copy-paste specifications, leading to two common errors in grinder applications:

- Mixing Technologies in a Common Manifold: Specifying centrifugal grinders to discharge into a force main shared by PC pumps is a recipe for disaster. The PC pumps (constant flow, high pressure) can hydraulically “dead head” the centrifugal pumps, preventing them from discharging or forcing them to operate at shut-off, leading to overheating.

- Ignoring Air Release Valves (ARVs): In LPS systems with undulating terrain, air pockets form at high points. Without proper combination ARVs designed for wastewater, air binding will increase head pressure, potentially stalling centrifugal grinders or causing excessive wear on PC stators.

O&M Burden & Strategy

Operators should plan for the following distinct maintenance activities:

- Cutter Adjustment (Annual): As cutter blades wear, the gap between the stationary and rotating element increases. If this gap exceeds 0.005-0.010 inches (manufacturer dependent), materials like wipes will “rope” rather than shred. Many modern pumps allow for external adjustment; older models require pulling the pump.

- Stator Inspection (PC Pumps – 3-5 Years): Monitor pump runtime. If the pump runs significantly longer to evacuate the same volume, the stator is worn (blow-by). Replace the stator before it fails completely.

- Grease Cap Removal: Grinder stations are notorious for grease accumulation. High-pressure washing of the floats and basin walls is required quarterly to prevent float hang-ups.

Design Details / Calculations

To properly size a unit from the Top 10 Grinder Pump Manufacturers for Water and Wastewater, specific hydraulic calculations are necessary.

Sizing Logic & Methodology

Step 1: Determine Peak Flow.

For single homes, a standard value is often used (e.g., 10-15 GPM). For multiple connections, use probability methods (like the Hunter Curve modified for pressure sewers) to determine the maximum simultaneous operation.

Step 2: Calculate Total Dynamic Head (TDH).

$$TDH = H_{static} + H_{friction} + H_{residual}$$

Where:

Hstatic: Elevation difference between the “pump off” level and the discharge point.

Hfriction: Friction loss in the pipe (Hazen-Williams C=130-140 for plastic pipe). Note: In small diameter pipes (1.25″-2″), friction losses escalate rapidly.

Hresidual: Residual pressure required at the connection to the main.

Step 3: Overlay System Curve on Pump Curves.

If using Centrifugal Grinders, ensure the intersection point is to the left of the run-out and to the right of the minimum stable flow. If using PC pumps, ensure the TDH does not exceed the pressure rating of the stator (typically 40-60 psi per stage). A 2-stage PC pump can handle ~80-100 psi.

Specification Checklist

Ensure your specification section (typically CSI MasterFormat 43 21 39) includes:

- [ ] Motor Service Factor: Minimum 1.15.

- [ ] Insulation Class: Class F or H required.

- [ ] Cable Entry: Epoxied, potted cable entry to prevent capillary wicking of water into the motor.

- [ ] Basin Anti-Flotation: Concrete ballast collar calculation included for fiberglass basins in high water table areas.

- [ ] Panel Rating: NEMA 4X (Stainless Steel or Fiberglass/Polycarb) with inner dead-front door.

FAQ Section

What is the difference between a grinder pump and a macerator pump?

While the terms are often used interchangeably, a grinder pump is designed for raw sewage and utilizes a robust metal cutter to shred solids like cloth, plastic, and wipes into a fine slurry. Macerators are typically lighter-duty units used in marine (boat) toilets or specific industrial food processing applications. For municipal wastewater, “grinder” is the correct specification term.

When should I specify a Progressive Cavity (PC) grinder over a Centrifugal grinder?

Specify a PC grinder when the Total Dynamic Head (TDH) is very high (over 140-150 feet) or when the discharge pressure varies significantly due to other pumps turning on and off in a shared force main. PC pumps maintain constant flow regardless of pressure, ensuring scour velocity is maintained. Centrifugal grinders are better for lower head, shorter runs, and where solids might be abrasive.

How long do grinder pumps typically last?

A well-specified grinder pump typically lasts 10-15 years. However, the wet-end components have different lifecycles. The cutter assembly may need adjustment or replacement every 3-5 years. In PC pumps, the elastomer stator typically lasts 5-7 years depending on use and grit content. The motor often outlasts the hydraulic components.

What is the impact of “flushable” wipes on the Top 10 Grinder Pump Manufacturers?

Despite the “flushable” label, non-dispersible wipes are the leading cause of pump failure. All top manufacturers have updated their cutter designs (e.g., Flygt’s N-impeller, Liberty’s V-Slice) specifically to handle this challenge. Older pump designs (pre-2010) are significantly more prone to binding on wipes than current models specified in this article.

Why is 2 feet per second (fps) velocity critical for grinder pump systems?

Grinder pumps create a slurry. If the velocity in the force main drops below 2 fps, the solids in that slurry will settle out of suspension. Over time, this sediment restricts the pipe diameter, increasing friction head and eventually causing a blockage or forcing the pump to operate at dangerous pressures.

Can I retrofit a new grinder pump into an old station?

Yes. Manufacturers like E/One, Liberty, and Myers offer “upgrade cores.” These are self-contained pump/motor/control units designed to slide into existing basins from other manufacturers. This is often more cost-effective than excavating and replacing the entire fiberglass wet well.

Conclusion

KEY TAKEAWAYS

- Technology First: Decide between Progressive Cavity (high head/constant flow) and Centrifugal (lower head/variable flow) before selecting a brand.

- Hardness Specs: Specify cutter materials with a minimum Rockwell C hardness of 55-60 to resist dulling.

- System Analysis: Never mix PC and Centrifugal pumps in the same pressure manifold without complex hydraulic modeling.

- Standardization: Limit the bid list to 2-3 compatible manufacturers to reduce the utility’s spare parts inventory burden.

- Velocity Matters: Ensure discharge piping is sized (typically 1.25″ – 2″) to maintain 2 fps scouring velocity.

- Panel Logic: Include “jam reversal” logic and redundant float/pressure controls in the electrical specification.

Selecting from the Top 10 Grinder Pump Manufacturers for Water and Wastewater requires a balance of hydraulic theory, materials science, and practical maintenance foresight. Whether designing a complex low-pressure sewer system for a new subdivision or retrofitting a failing lift station, the engineer’s goal is to maximize reliability.

By focusing on the specific strengths of manufacturers—such as E/One’s dominance in high-head PC applications or Flygt and Sulzer’s advancements in centrifugal solids handling—engineers can specify equipment that fits the hydraulic curve and the operational reality. The cost of a grinder pump is not the purchase price; it is the cost of the midnight call-out when the pump jams. Rigorous specification of materials, proper hydraulic sizing, and adherence to installation standards are the only safeguards against these failures.