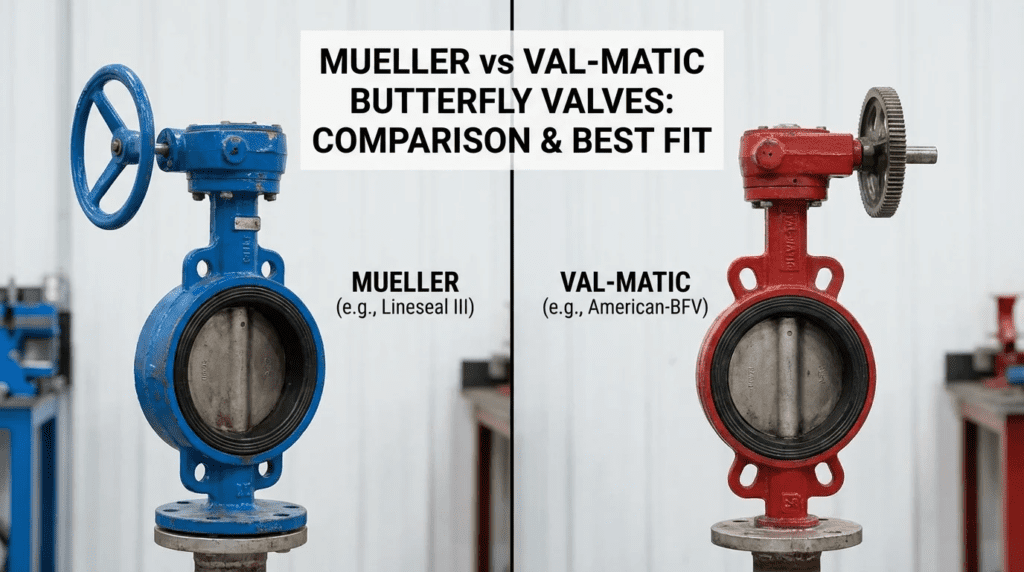

Mueller vs Val-Matic Butterfly Valves Equipment: Comparison & Best Fit

Introduction

In municipal water distribution and treatment plant design, the butterfly valve is often treated as a commodity specification—a “set and forget” component. However, statistical data from utility asset management plans suggests that valve failure during critical isolation events (such as main breaks) occurs in approximately 15-20% of aged assets. The cost of a seized or leaking valve during a catastrophic line break far exceeds the initial capital expenditure of the unit. This reality forces engineers to look beyond the generic “AWWA C504” label and scrutinize the specific design philosophies of manufacturers.

When analyzing Mueller vs Val-Matic Butterfly Valves Equipment: Comparison & Best Fit, engineers are evaluating two of the most dominant players in the North American water infrastructure market. Both manufacturers provide equipment that complies with AWWA standards, yet their approaches to seat retention, disc geometry, and shaft sealing differ significantly. These subtle engineering differences dictate performance in specific environments, such as high-cycle pump control versus infrequent isolation in buried service.

Mueller Co., particularly with its Lineseal family of valves, has long been a staple in distribution networks, favoring designs that prioritize robustness in buried applications. Val-Matic, conversely, often targets the plant and high-performance sector with the Series 2000, emphasizing hydraulic efficiency and adjustable seating mechanisms. This article provides a strictly technical comparison to assist consulting engineers and utility directors in determining the correct specification for their unique hydraulic profiles and operational constraints.

How to Select / Specify

Selecting between these manufacturers requires a detailed understanding of the application’s operating envelope. The “Mueller vs Val-Matic Butterfly Valves Equipment: Comparison & Best Fit” decision tree should be driven by the following engineering criteria.

Duty Conditions & Operating Envelope

The first step in specification is defining the hydraulic parameters. Both manufacturers offer valves rated for 150 psi (Class 150B) and 250 psi (Class 250B), but their performance at the margins differs.

- Flow Velocity: Standard AWWA C504 valves are rated for velocities up to 16 ft/s. However, if the application involves high-velocity discharge (e.g., emergency pump drawdown), verify the manufacturer’s specific disc strength calculations. Val-Matic’s lens-shaped disc is designed to minimize head loss and turbulence at higher velocities, which can be critical for energy calculations in high-flow transmission mains.

- Throttling Service: If the valve is intended for flow control rather than simple isolation, the disc geometry becomes critical. An offset disc design, commonly used by Val-Matic, allows for a wider effective control range before cavitation occurs compared to symmetric disc designs. Engineers must request

Cavitation Index data for the specific opening angles (typically 30° to 70°).

Materials & Compatibility

While ductile iron bodies (ASTM A536) are standard for both, the differentiation often lies in the seat and shaft materials.

- Seat Materials: EPDM is the industry standard for water service, offering excellent resistance to chloramines. Buna-N is preferred for wastewater with high hydrocarbon content. Mueller’s Lineseal III typically utilizes a molded-in or mechanically retained seat on the body. Val-Matic’s Series 2000 features a mechanically retained seat that is often field-adjustable. The specification must dictate whether “field replaceability” is a hard requirement.

- Disc Edge: The interface between the disc edge and the rubber seat is the primary wear point. 316 Stainless Steel is the preferred specification for the disc edge to prevent tuberculation that would shred the rubber seat. Ensure the specification requires a Type 316 stainless steel edge, regardless of whether the disc body is cast iron or ductile iron.

Hydraulics & Process Performance

The flow coefficient ($C_v$) determines the head loss across the valve when fully open. In energy-intensive pumping applications, a higher $C_v$ translates to lower lifetime energy costs.

Val-Matic typically markets their disc design as having a higher flow area and lower head loss. For a large plant (e.g., 50 MGD), a difference in head loss of 0.5 psi across a valve bank can result in significant annual pumping costs. Engineers should request certified flow test data to compare the $C_v$ values of the specific models (e.g., Mueller Lineseal XP vs. Val-Matic Series 2000) for the specified diameter.

Installation Environment & Constructability

Buried Service: For distribution systems, Mueller has a distinct advantage in market ubiquity and supply chain familiarity among contractors. Their valves are designed with the assumption of “bury and forget.” The critical specification here is the actuator. Buried service requires a grease-packed, sealed gear actuator (typically varying from IP67 to IP68 standards depending on groundwater levels).

Plant/Gallery Service: In treatment plant pipe galleries, Val-Matic’s design often wins favor due to the adjustability of the seat without removing the valve from the line (in certain models) and the compact nature of their actuator mounting options. Space constraints in existing galleries often dictate the valve selection based on the “F” dimension (face-to-face) and actuator orientation.

Reliability, Redundancy & Failure Modes

The primary failure mode for butterfly valves is shaft seizure or seat degradation leading to pass-through leakage.

- Shaft Sealing: Look for V-type packing or self-adjusting chevron packing. Both manufacturers offer substantial shaft sealing, but preference should be given to designs that allow packing replacement under pressure (if safety protocols permit) or without major disassembly.

- Seat Failure: If a seat gets cut by debris, leakage occurs. A bonded seat (common in smaller Mueller valves) usually requires sending the valve back to the factory or replacing the unit. A mechanically retained seat (Val-Matic standard) allows for potential field replacement, though this is a complex maintenance task rarely performed perfectly in the field.

Lifecycle Cost Drivers

When analyzing Mueller vs Val-Matic Butterfly Valves Equipment: Comparison & Best Fit, the Total Cost of Ownership (TCO) equation must include:

- Acquisition Cost: Mueller is often more competitively priced for bulk distribution valve procurement.

- Energy Cost: Val-Matic may offer ROI advantages in high-head, continuous-pumping applications due to hydraulic efficiency.

- Maintenance Labor: If the utility forces (operators) are not trained in seat adjustment/replacement, the “repairable” feature of a more expensive valve becomes moot, and the valve becomes a replacement item upon failure regardless of brand.

Comparison Tables

The following tables provide a side-by-side engineering evaluation of the equipment. These comparisons focus on the standard municipal product lines (e.g., AWWA C504 compliant series) typically specified for water and wastewater service.

| Feature / Attribute | Mueller (Lineseal III / XP) | Val-Matic (Series 2000) | Engineering Significance |

|---|---|---|---|

| Primary Seat Design | Molded-in or Mechanically Retained (depending on size) | Mechanically Retained / Adjustable (Tri-Loc system) | Adjustable seats allow for leakage correction after years of service; molded seats are tamper-proof but harder to repair. |

| Disc Geometry | Streamlined, typically symmetric or slightly offset | Lens-shaped, double offset | Double offset reduces seat interference during travel, lowering torque requirements and wear. |

| Hydraulic Efficiency | Standard AWWA Compliance | High $C_v$ Focus | Critical for pump discharge applications where head loss equals energy dollars. |

| Shaft Sealing | V-Type Packing / O-Rings | V-Type Packing (adjustable) | Adjustable packing extends the time between major maintenance intervals. |

| Typical Best Fit | Buried Distribution, Transmission Mains | Plant Galleries, Pump Stations, High-Cycle Service | Aligns equipment strengths with environmental constraints. |

| Application Scenario | Best Fit Considerations | Mueller Suitability | Val-Matic Suitability | Key Decision Driver |

|---|---|---|---|---|

| Buried Distribution Isolation | Infrequent operation, zero maintenance access, robust actuator. | Excellent – Industry standard, rugged design. | Good – Higher cost may not yield ROI underground. | CAPEX & Ruggedness |

| WTP Filter Effluent | Modulating service, frequent cycling, high consequence of failure. | Good – If properly sized for throttling. | Excellent – Offset disc offers better control range. | Control Precision |

| High Service Pump Discharge | High flow, continuous operation, energy sensitivity. | Good – Check head loss curves. | Excellent – Lower head loss design saves energy. | OPEX (Energy) |

| Wastewater Aeration Control | Air service, high temperature potential. | Limited – Requires specific trim. | Good – High temp seat options available. | Material Compatibility |

Engineer & Operator Field Notes

Real-world performance often deviates from catalog specifications. The following notes are compiled from commissioning reports and operator feedback regarding Mueller vs Val-Matic Butterfly Valves Equipment: Comparison & Best Fit.

Commissioning & Acceptance Testing

During the Factory Acceptance Test (FAT) or Site Acceptance Test (SAT), engineers must verify seat integrity. A common issue is the “dry seat” test. Rubber seats may stick after long storage periods.

- Torque Verification: Ensure that the actuator stops are set correctly. Over-torquing a butterfly valve in the closed position does not improve the seal; it compresses the rubber beyond its recovery point, leading to premature failure.

- Cycle Testing: Run the valve full open to full close at least 3 times. Listen for “popping” noises, which indicate the disc edge is catching on the seat rubber rather than sliding smoothly.

Common Specification Mistakes

Another frequent error is ignoring the actuator extension shaft in buried applications. If the ground settles, a rigid extension shaft can transfer load to the valve bonnet, causing misalignment and leakage. Specifications should require a slip-joint or intermediate coupling to isolate ground loads.

O&M Burden & Strategy

Valve Exercising: This is the single most critical maintenance task. Both Mueller and Val-Matic valves require annual or semi-annual cycling to prevent calcification and rubber adhesion. Mueller valves in distribution systems are notoriously prone to freezing if left static for 5+ years.

Packing Adjustment: Val-Matic’s accessible packing gland allows operators to tighten packing if shaft leakage is observed. Operators must be trained to tighten these evenly; uneven tightening can score the shaft. Mueller’s designs often use O-rings or self-adjusting packing that requires less intervention but offers fewer options if a leak develops.

Troubleshooting Guide

- Symptom: Valve won’t close completely.

Cause: Debris in the bottom of the body (common in wastewater) or actuator limit switch drift.

Action: Back-flush by opening slightly and closing. Check actuator stops. Do not force! - Symptom: Leakage past seat.

Cause: Seat wear, disc corrosion, or insufficient seating torque.

Action: For Val-Matic, attempt seat adjustment (Tri-Loc). For Mueller, check if the debris is lodged. Verify actuator torque output.

Design Details / Calculations

Sizing Logic & Methodology

Sizing a butterfly valve is not simply matching the line size. While line-size valves are common in isolation duties, throttling valves must be sized based on velocity and pressure drop.

Velocity Calculation:

$$V = frac{0.4085 times Q}{d^2}$$

Where $V$ is velocity (ft/s), $Q$ is flow (gpm), and $d$ is valve diameter (inches).

Limit: Keep $V < 16$ ft/s for standard C504 applications. If $V > 16$ ft/s, consult the manufacturer for torque increases.

Torque Calculations

Actuator sizing depends on three torque components:

- Seating Torque ($T_s$): Friction between the seat and disc edge.

- Bearing Torque ($T_b$): Friction at the shaft bearings due to hydrostatic load.

- Dynamic Torque ($T_d$): Fluid dynamic forces tending to close the valve (flow reversal).

Val-Matic’s offset disc design generally results in lower seating torque compared to symmetric designs, potentially allowing for smaller actuators on large valves. Engineers should require torque calculation sheets in the submittal package that show safety factors (typically 1.25 to 1.5) applied to the worst-case operating conditions.

Standards & Compliance

When writing the spec for Mueller vs Val-Matic Butterfly Valves Equipment: Comparison & Best Fit, cite the following:

- AWWA C504: Rubber-Seated Butterfly Valves.

- NSF/ANSI 61 & 372: Drinking Water System Components (Lead-Free).

- ASTM A536: Ductile Iron Castings (Standard for Body/Disc).

- Proof of Design (POD): Require evidence that the manufacturer has performed the cycle testing (typically 10,000 cycles) required by AWWA standards for the specific model offered.

Frequently Asked Questions

What is the difference between AWWA C504 and C516 butterfly valves?

AWWA C504 is the standard for rubber-seated butterfly valves typically used in waterworks, covering sizes 3″ to 72″, with pressure classes up to 250 psi. AWWA C516 covers large-diameter valves (up to 108″ and beyond) and is often applied to vacuum service or higher cycle applications. For most municipal distribution and plant piping (up to 72″), C504 is the governing standard for both Mueller and Val-Matic product lines.

How does the “Tri-Loc” seat system in Val-Matic valves work?

The Tri-Loc system is a Val-Matic feature where the rubber seat is mechanically retained in the valve body but can be adjusted. The seat is held by a series of stainless steel segments and locking screws. This allows maintenance personnel to tighten or adjust the compression of the seat against the disc edge in the field to stop minor leaks, extending the valve’s life without requiring full removal or rebuilding.

Can Mueller Lineseal valves be used for throttling service?

Yes, Mueller Lineseal valves can be used for throttling, but with limitations. Like most butterfly valves, the effective linear flow control range is typically between 30° and 70° open. Operating continuously below 30° can cause seat erosion due to high velocity (wire drawing) and cavitation. Engineers should verify the cavitation index for the specific operating point.

Why is the “offset” disc design important in valve selection?

An offset disc (eccentric) design moves the shaft axis away from the centerline of the disc and the pipe. This geometry causes the disc to “cam” into the seat only at the very end of the closing stroke. This reduces continuous friction between the rubber and the metal disc edge during travel, lowering operating torque and reducing wear on the rubber. Val-Matic heavily utilizes this design to improve longevity and reduce actuator size.

Which valve is better for buried service: Mueller or Val-Matic?

Both are capable, but Mueller is often considered the “best fit” for standard buried distribution service due to cost-effectiveness and a design optimized for infrequent isolation. Val-Matic valves are often seen as “over-qualified” for simple buried isolation unless the line is critical transmission where head loss is a major financial factor. The choice often comes down to budget versus hydraulic performance requirements.

What is the typical lifespan of these butterfly valves?

In clean water applications with proper exercising, both Mueller and Val-Matic butterfly valves typically last 20 to 30 years. However, the seat (rubber component) is the limiting factor. In high-chloramine or high-ozone environments, rubber degradation may occur sooner (10-15 years) if the wrong elastomer is specified. Mechanically retained seats (Val-Matic) offer a path to extend life via repair, whereas molded seats (some Mueller models) may require full valve replacement.

Conclusion

Key Takeaways

- Application Splits: Specification strategy typically favors Mueller for general buried distribution and Val-Matic for plant process, pump control, and accessible gallery piping.

- Seat Technology: The choice between molded-in (tamper-proof, disposable) and mechanically retained (adjustable, repairable) is the primary differentiator.

- Hydraulics Matter: For continuous pumping, calculate the Net Present Value (NPV) of energy costs using the specific $C_v$ of each valve. Val-Matic often holds an edge here.

- Specification Safety: Always specify “AWWA C504 Proof of Design” and required actuator safety factors (1.5 recommended) to avoid undersized actuators.

- Maintenance Reality: If the facility lacks a skilled maintenance crew for seat adjustment, the “repairable” advantages of premium valves may not be realized.

Ultimately, the analysis of Mueller vs Val-Matic Butterfly Valves Equipment: Comparison & Best Fit is not about declaring a superior manufacturer, but rather matching the equipment’s engineering DNA to the specific problem. Mueller provides a robust, standardized solution that serves as the backbone of North American water distribution networks—reliable, cost-effective, and familiar to every contractor.

Val-Matic offers a more feature-rich, hydraulically optimized solution that shines in treatment plants and pump stations where flow efficiency, adjustability, and control precision justify a potentially higher initial investment. Engineers should utilize the lifecycle cost analysis and duty cycle constraints outlined in this guide to make the final determination, ensuring that the selected equipment delivers reliability commensurate with the criticality of the service.