Top OEMs for Altitude Valves

Introduction

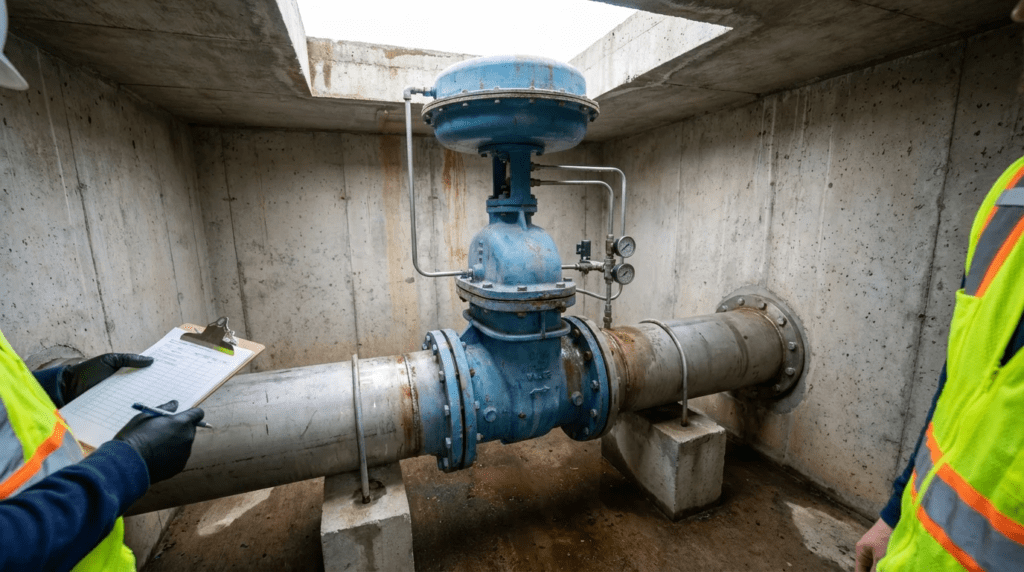

In municipal water distribution and industrial fluid handling, the management of reservoir and tank levels is a critical operational requirement. The altitude valve serves as the primary mechanical safeguard against overflows and the central mechanism for maintaining the hydraulic grade line within a specific pressure zone. These valves are specialized automatic control valves (ACVs) designed to shut off flow at a preset high-water level and reopen when the system pressure drops or the tank level recedes.

The application of altitude valves extends from elevated water towers in small municipalities to massive ground storage reservoirs in metropolitan water districts. Unlike standard isolation valves, altitude valves operate autonomously via hydraulic pilots, utilizing line pressure to actuate the main valve without the need for external power sources such as electricity or compressed air. This characteristic makes them indispensable in remote locations where SCADA connectivity or power infrastructure may be limited or nonexistent.

From a regulatory and safety perspective, the failure of an altitude valve carries significant consequences. A valve that fails to close results in tank overflows, leading to water loss, potential property damage, environmental erosion, and regulatory fines for unaccounted water. Conversely, a valve that fails to open can lead to system depressurization, causing backflow events, cavitation in booster pumps, and the loss of fire protection capabilities. Therefore, the selection of the Original Equipment Manufacturer (OEM) is not merely a procurement formality but a critical engineering decision that dictates the long-term reliability, maintainability, and lifecycle cost of the asset.

Consulting engineers and utility operators must evaluate manufacturers based on their engineering pedigree, the robustness of their pilot systems, the quality of casting and machining, and the availability of support for complex hydraulic troubleshooting. This article provides a comprehensive technical analysis of the leading OEMs for altitude valves—Singer Valve, Cla-Val, Bermad, Ross Valve Manufacturing, and Watts—focusing on their design philosophies, technical capabilities, and suitability for various engineering applications.

How to Select This Valve Type

Selecting the correct altitude valve requires a granular understanding of the system hydraulics and the specific operational philosophy of the storage facility. Engineers cannot simply specify a line-size valve; doing so frequently results in oversizing, instability, and premature failure. The following criteria define the engineering path to a robust specification.

Valve Function and Duty Cycle

Altitude valves are categorized by their flow characteristics and control logic. The most basic distinction is between one-way and two-way flow. A one-way altitude valve controls flow into the tank only; a separate check valve or bypass line allows flow out of the tank to the distribution system. A two-way altitude valve allows flow in both directions, closing only when the high-water level is reached to prevent overflow, but opening immediately when distribution pressure drops below the tank head.

Furthermore, engineers must decide between on/off (differential) control and modulating control. Modulating valves throttle the flow to maintain a constant level, which can lead to “wire-drawing” damage on the valve seat if the flow rates are consistently low. On/off valves, which open fully at a low set point and close fully at a high set point, are generally preferred for water towers to encourage tank turnover (mixing) and prevent water age issues, while also reducing wear on the valve trim.

Pressure and Flow Conditions

The hydraulic conditions dictate the valve body style and trim. The Cavitation Index must be calculated for the valve in its most throttled position. In applications where a tank is filled from a high-pressure zone, the pressure differential across the valve can be extreme. If the discharge pressure is close to the vapor pressure of the fluid relative to the inlet pressure, cavitation will occur, destroying standard valve seats and causing vibration. In these scenarios, anti-cavitation trim—often consisting of slotted cages or dual-ported seats—is a mandatory specification requirement.

Materials of Construction

Standard municipal specifications typically call for ASTM A536 Ductile Iron bodies, which offer superior tensile strength and shock resistance compared to cast iron, particularly in water hammer scenarios. For the internal trim (seat, disc guide, and stem), Stainless Steel (303 or 316) is the engineering standard for longevity, resisting both corrosion and erosion. The elastomeric components—primarily the diaphragm and seals—should be EPDM or Buna-N, with EPDM being preferred for chloraminated water systems due to its resistance to chloramine degradation.

Coatings are equally critical. Fusion Bonded Epoxy (FBE) coating, applied internally and externally in accordance with AWWA C550, is essential for corrosion protection and preventing tuberculation that can impede flow or clog pilot sensing lines.

Sealing Mechanisms and Actuation

Most modern altitude valves are diaphragm-actuated globe or angle pattern valves. The diaphragm separates the line pressure in the cover chamber from the process water. When the cover chamber is pressurized (via the pilot), the valve closes; when vented, it opens. The quality of the diaphragm is paramount. High-performance OEMs utilize nylon-reinforced rubber diaphragms that are pre-formed to minimize stress during the stroke. Some designs employ a rolling diaphragm, which provides consistent effective area throughout the stroke, improving control stability at low flows.

Alternatively, piston-actuated valves are used in heavy-duty or high-pressure applications. Pistons use a rigid seal (often with leather or synthetic cups) moving within a liner. While more robust against catastrophic pressure spikes, pistons can be more sensitive to debris and friction than diaphragms.

Sensing and Pilot Systems

The pilot system is the “brain” of the altitude valve. It typically consists of a spring-loaded diaphragm pilot that senses the static head of the tank. The connection of the sensing line is a common point of failure. The sensing line must tap into the tank or a static pressure point away from the turbulence of the valve outlet. If the sensing line is connected to the turbulent flow at the valve discharge, the valve will experience “false head” readings, leading to erratic cycling (hunting). Engineers must specify the location and material (usually copper or stainless steel tubing) of the sensing line clearly.

Maintenance and Serviceability

Lifecycle costs are driven by ease of maintenance. Top-entry designs allow operators to inspect and replace internal trim without removing the valve body from the pipeline. This is a critical feature for large valves (12 inches and larger). Engineers should also evaluate the complexity of the pilot system. While complex pilots offer features like delayed opening or adjustable closing speeds, they also present more small-bore tubing and orifices that can clog. A “less is more” approach often benefits long-term reliability in water systems with high turbidity or mineral content.

Comparison Table

The following table provides a technical comparison of the top OEMs for altitude valves. This data is intended to assist engineers and operations managers in evaluating which manufacturer’s design philosophy aligns best with their specific project constraints. It should be interpreted not as a hierarchical ranking, but as a guide to application fit, highlighting the mechanical nuances that differentiate each brand in the context of municipal and industrial water infrastructure.

| OEM | Core Technology | Typical Applications | Engineering Strengths | Maintenance & Operational Considerations |

|---|---|---|---|---|

| Singer Valve | Rolling Diaphragm (ACV) | Municipal distribution, high-differential pressure zones, leakage management. | Low Flow Stability: Rolling diaphragm design ensures stable control down to near-zero velocity. Anti-Cavitation: Superior trim options for breaking down high pressure drops. |

Requires clean pilot lines; pilot system is precise but sensitive to debris. Single rolling diaphragm simplifies internals but requires careful handling during replacement. |

| Cla-Val | Diaphragm Actuated Globe/Angle | General municipal water, fire protection, fuels, marine. | Ubiquity: The industry standard specification; massive installed base. Versatility: Extremely wide range of pilots and added functions (e.g., solenoid override, check features). |

Parts availability is excellent worldwide. Complexity of pilot trees on multi-function valves can be daunting for untrained technicians. Standard flat diaphragms may have higher hysteresis than rolling types. |

| Bermad | Double Chamber / Diaphragm | Irrigation, municipal water, pressure management. | Hydraulic Efficiency: Double chamber design allows for quicker reaction and lower opening pressures. Flow Path: “Y” pattern bodies offer high flow coefficients (Cv). |

Unique “Y” body shape requires specific installation dimensions. The double chamber design is distinct and requires operators to understand the specific tubing layout different from single-chamber standards. |

| Ross Valve | Piston Actuated | Raw water, heavy industrial, large-scale municipal transmission. | Durability: Piston design is incredibly rugged and handles dirty water/debris better than diaphragms. Service Life: Known for decades of service before major overhaul. |

Heavier moving parts may have slower reaction times (beneficial for surge). Maintenance involves piston seals/packing which differs from diaphragm replacement. Higher initial weight/cost often justified by longevity. |

| Watts | Diaphragm Actuated (ACV) | Commercial plumbing, municipal water, fire protection. | Standardization: Stainless steel pilot tubing often standard. Integration: Strong integration with backflow prevention and commercial water systems. |

Excellent fit for standard municipal applications. May have fewer custom “engineered special” options for extreme hydraulic conditions compared to niche industrial manufacturers. |

Top OEM Manufacturers

Singer Valve

Singer Valve, now a brand under Mueller Water Products, is widely recognized among engineering consultants for its focus on solving difficult hydraulic challenges, particularly regarding pressure management and cavitation. In the context of altitude valves, Singer’s primary differentiator is the rolling diaphragm technology found in their main valves (Series 106/206). Unlike flat diaphragms that stretch and can distort under varying pressures, the rolling diaphragm unrolls along the valve bonnet.

This design feature provides a constant effective area throughout the entire stroke of the valve. For altitude applications, this results in extremely stable modulation and precise level control, even at low flow rates where other valves might experience “chatter.” Singer is typically the preferred specification when the altitude valve must also perform pressure sustaining or pressure reducing functions simultaneously, or when the fill line has high differential pressure requiring anti-cavitation trim. Their pilots are precision-machined, and the company offers robust “dual-point” set (opening and closing) capabilities to ensure adequate tank turnover.

Cla-Val

Cla-Val is arguably the most recognized name in the automatic control valve market, often serving as the “basis of design” for municipal specifications. The Cla-Val Model 100-01 Hytrol valve is the platform upon which their altitude configurations (Series 210) are built. Cla-Val’s strength lies in the sheer breadth of their catalog and the interchangeability of their components. For altitude valves, they offer one-way, two-way, and modulating options, along with delayed-action pilots that are mechanically adjustable.

The engineering merit of Cla-Val lies in the robustness of their casting and the modularity of their pilot system. A standard Cla-Val altitude valve can be easily retrofitted in the field with additional controls, such as solenoids for SCADA override or rate-of-flow limiters, without removing the main valve from the line. Their “X101” valve position indicator is a standard industry reference. While their traditional design utilizes a flat diaphragm which has stood the test of time, they typically rely on the pilot system’s sensitivity to manage the hysteresis inherent in that design.

Bermad

Bermad brings a distinct engineering philosophy centered on hydraulic efficiency and composite materials alongside traditional metals. While they offer standard metal ACVs, they are notable for their “Y” pattern bodies and double-chamber technologies. In a double-chamber valve, the diaphragm is subjected to hydraulic pressure on both sides (opening and closing chambers), rather than relying solely on line pressure versus a spring.

For altitude applications, the double-chamber design allows for immediate response to level changes and, crucially, allows the valve to open fully at very low line pressures. This is particularly advantageous in gravity-fed systems where the driving head to fill the tank is minimal. Bermad’s 700 Series valves are designed for high-pressure and critical municipal applications, featuring excellent flow geometry that minimizes head loss across the valve—a critical factor when energy costs for pumping are calculated over the asset’s lifecycle.

Ross Valve Manufacturing

Ross Valve Manufacturing occupies a unique niche in the sector, favoring piston-actuated designs over the diaphragm-actuated styles prevalent elsewhere. A Ross altitude valve operates using a sliding piston within a cylinder. This design is inherently more robust and less prone to sudden catastrophic failure than a rubber diaphragm, which can tear. The piston design also allows the valve to handle raw water or water with higher suspended solids more effectively, as the scraping action of the piston can clear minor debris that might foul a diaphragm seat.

Engineers often specify Ross valves for large-diameter transmission mains, raw water reservoirs, and older infrastructure where water quality is variable. The heavy-duty construction of Ross valves typically translates to a longer Mean Time Between Failures (MTBF). They are also highly customizable; Ross is known for manufacturing “drop-in” replacements for obsolete valves, matching face-to-face dimensions of valves that have been in service for 50+ years.

Watts

Watts, a massive conglomerate in the water industry, produces a comprehensive line of Automatic Control Valves (formerly associated with brands like Ames and Watts ACV). Their altitude valves are engineered for reliability and compliance with AWWA standards. A key engineering feature often seen in Watts specifications is the standardization of stainless steel pilot tubing and fittings as a baseline, whereas other manufacturers may offer copper or brass as standard with stainless as an upgrade.

Watts altitude valves (Series 1100) are designed for easy maintenance, with a focus on simple cover removal and accessible seat rings. While they may not specialize in the extreme high-pressure/cavitation niches as aggressively as Singer, or the heavy industrial piston designs of Ross, they provide a highly reliable, cost-effective solution for the vast majority of standard municipal water tower and ground storage applications. Their synergy with backflow prevention products also simplifies procurement and support for plant engineers managing commercial or mixed-use facilities.

Application Fit Guidance

Selecting the right OEM often depends on the specific environmental and hydraulic context of the installation. The following guidance aligns manufacturer strengths with common engineering scenarios.

Municipal Water Distribution (Towers & Standpipes)

For standard potable water towers, Cla-Val and Watts are the dominant choices. Their parts availability through local distribution networks is critical for municipal operators who cannot afford downtime. The ability to easily retrofit solenoid overrides for SCADA integration makes these brands highly suitable for modern smart water grids. If the tower requires significant turnover to prevent ice formation or stagnation, specifying a valve with a wide “differential” pilot (adjustable open/close gap) from these manufacturers is best practice.

High-Pressure & Mountainous Systems

In applications with high static heads—such as filling a lower-zone reservoir from a high-zone feed—cavitation is a primary failure mode. Singer Valve is frequently the preferred engineering choice here due to their proprietary anti-cavitation trim designs. Their dual-diaphragm or rolling diaphragm technology provides the stability required to throttle against high differential pressures without vibration.

Raw Water & Industrial Wastewater

When the fluid medium is not perfectly clean potable water—for instance, raw water intake for a treatment plant or industrial process water containing grit—Ross Valve Manufacturing is the standout candidate. The piston actuation is far more forgiving of particulates than diaphragm valves. Diaphragms can suffer from abrasion or get punctured by sharp debris, whereas a piston with rugged seals will continue to operate.

Low Pressure / Gravity Feed

In scenarios where the supply pressure is very low (e.g., a gravity-fed tank with minimal head), Bermad‘s double-chamber design offers distinct advantages. The hydraulic assistance provided by the double chamber ensures the valve opens fully and closes tightly even when the available line pressure is marginal, ensuring the tank fills as rapidly as possible.

Engineer & Operator Considerations

Beyond the selection of the OEM, the successful deployment of an altitude valve relies on system design and maintenance protocols.

Installation Best Practices

A common engineering oversight is the omission of isolation valves and air release valves. Every altitude valve must be flanked by isolation valves (gate or butterfly) to facilitate maintenance. Furthermore, an air release valve must be installed on the downstream side of the altitude valve (or on the valve bonnet if designed for it). When the altitude valve closes, the downstream line can become vacuum-bound or air-locked, creating erratic operation upon reopening. Additionally, the sensing line must be installed correctly. It should tap into the reservoir at a point of static pressure, well away from the inlet turbulence. Using the valve’s internal sensing port is only acceptable if the tank is immediately adjacent and the line loss is negligible.

Common Specification Mistakes

Oversizing is the enemy of control valve life. Engineers often size the altitude valve to match the line size (e.g., a 12-inch valve on a 12-inch pipe). However, if the normal flow rate only requires a 6-inch valve opening, a 12-inch valve will operate near the “cracked open” position. This causes seat chatter, cavitation, and premature wear. It is almost always better to size the valve based on flow coefficient (Cv) requirements rather than pipe diameter, often resulting in a valve one size smaller than the line, installed with reducers.

Maintenance and Spare Parts

Operators should prioritize the pilot system during routine maintenance. The pilot strainer is the first line of defense; if it clogs, the valve will fail (usually in the closed position, but potentially open depending on the pilot type). A monthly or quarterly blow-down of the Y-strainer is recommended. Regarding spare parts, diaphragm kits and rubber goods have a shelf life. Utilities should avoid stockpiling rubber parts for more than 5 years. Instead, standardized on an OEM that guarantees rapid shipment of rebuild kits.

Cold Weather Considerations

In northern climates, altitude valves are susceptible to freezing, particularly the small-bore pilot tubing which holds static water. If the valve is in a vault, heating is required. If the sensing line runs externally up a tank, it must be heat-traced and insulated. Failure to do so will result in the sensing line freezing, usually causing the valve to “think” the tank is full (or empty, depending on failure mode), leading to overflow or supply loss.

Conclusion

The altitude valve is a linchpin in hydraulic storage management. While the fundamental concept of using line pressure to control level is consistent across the market, the execution differs significantly among top OEMs. Singer Valve excels in high-differential, precision control applications; Cla-Val offers unmatched versatility and market ubiquity; Bermad provides high-efficiency hydraulic designs; Ross Valve dominates the heavy-duty, dirty-water niche; and Watts delivers reliable, standard-compliant solutions for broad municipal and commercial use.

For the consulting engineer and the utility manager, the goal is to match the valve’s mechanical characteristics—diaphragm vs. piston, single vs. double chamber, anti-cavitation trim requirements—to the specific hydraulic reality of the site. By prioritizing accurate sizing, proper sensing line installation, and ease of maintenance over the lowest initial bid, water systems can achieve decades of reliable, overflow-free operation.