Aeration Blower Types: An In-depth Exploration

Aeration blowers are essential in various industries, particularly in wastewater treatment facilities, aquaculture, and chemical processing sectors. The primary function of these blowers is to supply air to systems requiring oxygenation or agitation. This prevents anaerobic conditions, promotes bacterial growth for decomposition, and ensures optimal process conditions. This article delves into different types of aeration blowers, examining their operations, applications, advantages, and disadvantages.

Introduction to Aeration Blowers

Importance of Aeration

Aeration is a critical process in many industries, aimed at introducing air into a liquid, promoting oxygen transfer. In wastewater treatment, aeration is essential for the biological degradation of organic pollutants. In aquaculture, it maintains oxygen levels to support healthy aquatic life.

Basics of Aeration Blowers

Aeration blowers are mechanical devices designed to inject air into liquids. They come in different shapes and sizes but share the common goal of ensuring sufficient oxygen transfer rates and efficient mixing.

Types of Aeration Blowers

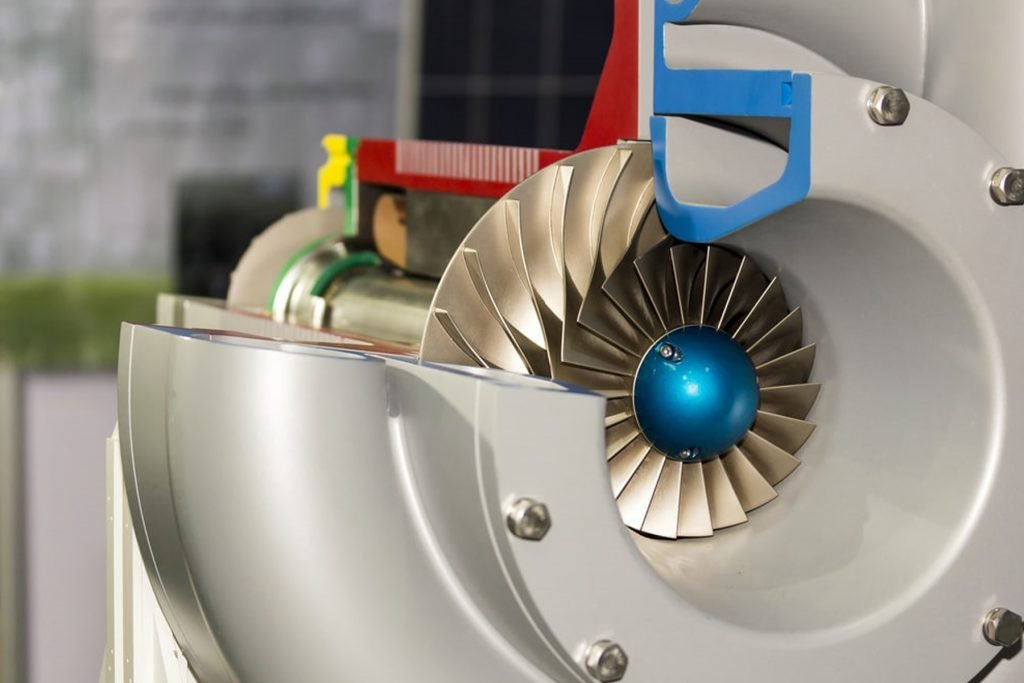

Centrifugal Blowers

Centrifugal blowers, also known as radial blowers, utilize centrifugal force to move air. They consist of a rotating impeller inside a casing. As the impeller spins, it accelerates the air outward to the edge of the casing, converting velocity into pressure.

Applications

- Wastewater Treatment: Used in large-scale aeration tanks.

- HVAC Systems: For air handling and ventilation.

- Industrial Processes: Common in pneumatic conveying and cooking operations.

Advantages

- High Efficiency: Capable of producing high airflow rates at lower energy consumption.

- Stable Performance: Offers consistent pressure output.

- Durability: Relatively long lifespan and low maintenance.

Disadvantages

- Complex Installation: Requires precise alignment and balancing.

- Noise Levels: Can be noisier compared to some other types.

Positive Displacement Blowers

Positive displacement blowers trap a specific volume of air and then force it into the aeration system. They come in various designs, including rotary lobe, screw, and piston blowers.

Rotary Lobe Blowers

Rotary lobe blowers utilize two intermeshing rotors to displace air. The rotors spin in opposite directions, trapping air in the pockets formed between the rotors and the casing.

Applications

- Wastewater Treatment: Often used in aeration tanks and digesters.

- Industrial Vacuum: Applied in conveying systems.

- Pneumatic Transport: Useful in material handling operations.

Advantages

- Simplicity: Simple design and robust construction.

- Variable Flow Rates: Capable of adjusting flow rates.

- Low Maintenance: Minimal moving parts contribute to lower maintenance.

Disadvantages

- Noise: Known for being noisy, especially at higher pressures.

- Efficiency: Less efficient than centrifugal blowers at higher pressures.

Screw Blowers

Screw blowers utilize twin helical screws to compress and transport air. These screws rotate and mesh in a synchronized manner, creating a continuous flow of air.

Applications

- Wastewater Treatment: Suitable for aeration systems requiring continuous airflow.

- Process Industries: Used in food processing and chemical plants for fermentation processes.

Advantages

- Efficiency: High efficiency over a broad range of operating conditions.

- Noise Reduction: Quieter than rotary lobe blowers due to less pulsation.

- Thermal Management: Reduced heat generation compared to other positive displacement blowers.

Disadvantages

- Cost: Generally more expensive to purchase and maintain.

- Complexity: More complex design resulting in intricate maintenance procedures.

Piston Blowers

Piston blowers use a reciprocating piston mechanism to displace air. The air is drawn into a cylinder and compressed as the piston moves through its cycle.

Applications

- Medical Applications: Often used in respiratory devices and ventilators.

- Precision Aeration: Applied in systems where precise air control is critical.

Advantages

- Precision: Capable of providing highly accurate air delivery.

- Pressure Capabilities: Can achieve very high pressures.

Disadvantages

- Complexity: Requires frequent maintenance due to more moving parts.

- Noise and Vibration: Tends to be noisier and more prone to vibration issues.

Liquid Ring Blowers

Liquid ring blowers, also known as liquid ring compressors, employ a rotating assembly that includes a pump casing partially filled with liquid. Air is drawn into the casing, and the liquid forms a moving ring that compresses the air.

Applications

- Vacuum Processing: Common in applications requiring low-pressure vacuum.

- Dewatering Systems: Utilized in industries that need continuous dewatering.

- Steam Recovery: Used in systems recovering vapor and steam.

Advantages

- Reliability: Robust and reliable performance.

- Low Noise Levels: Operates more quietly than other blower types.

- Handles Contaminants: Can handle air mixed with liquids or small amounts of particulates.

Disadvantages

- Efficiency: Generally less efficient compared to centrifugal blowers.

- Complexity: Requires careful maintenance to manage the liquid medium and avoid leaks.

Regenerative Blowers

Regenerative blowers, also known as side channel blowers, use an impeller with numerous blades that pass through a channel. Air is drawn into the impeller and circulated several times within the blower housing to increase pressure before being discharged.

Applications

- Aquaculture: Maintains oxygen levels in fish farms.

- Vacuum Lifting: Used in material lifting and conveying systems.

- OEM Equipment: Incorporated into various OEM systems requiring low-pressure, high-volume airflow.

Advantages

- Compact Design: Small footprint and lightweight.

- Low Maintenance: Minimal wear components, leading to reduced maintenance.

- Operational Versatility: Can be used in both pressure and vacuum applications.

Disadvantages

- Performance Limitations: Less effective for high-pressure applications.

- Efficiency: May have lower efficiency at higher pressures compared to centrifugal blowers.

Factors to Consider When Choosing Aeration Blowers

- Specific Application Requirements: Different systems require different airflow rates, pressures, and duty cycles.

- Energy Efficiency: Higher efficiency can result in significant cost savings over time.

- Noise and Vibration: Some blower types are inherently quieter and produce less vibration.

- Maintenance Requirements: Consider the maintenance schedule and ease of access.

- Initial Cost vs. Lifetime Cost: Factor in energy consumption and maintenance costs over time.

Advancements in Aeration Blower Technology

- Smart Blowers: Real-time monitoring enables predictive maintenance and optimization.

- Variable Speed Drives (VSD): Adjust blower speeds to match process needs, improving efficiency.

- Noise Reduction Technologies: Developments in acoustic engineering have led to quieter blowers.

Conclusion

Aeration blowers are crucial across industries. Understanding the nuances of each type and staying informed about technological advancements helps industries optimize aeration processes for better performance, sustainability, and cost-efficiency.